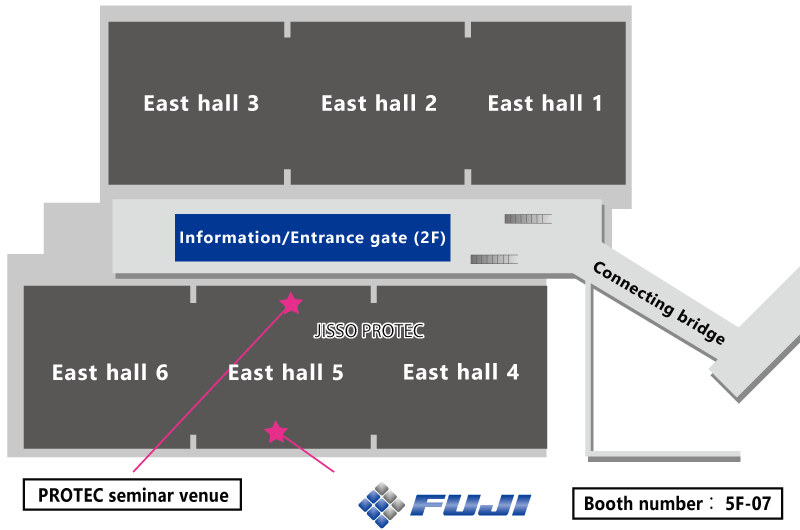

Dates: May 31 (Wed) - June 2 (Fri), 2023

Venue: Tokyo Big Sight, East Hall 5

Fuji booth number: 5F-07

The JISSO PROTEC 2023 Exhibition is to be held for 3 days from May 31st (Wednesday) to June 2nd (Friday) at Tokyo Big Sight and Fuji will be there exhibiting our latest machines.

At this exhibition, we will be showcasing the AIMEXR SMT pick and place machine for the first time in Japan, which comes equipped with core technologies that are at the heart of our new "R" machine lineup. Detailed explanations will be available on-site for the features of these machines and the newly developed RH heads that can also be used with NXTR machines. We will also demonstrate proposals for automation solutions on a line consisting of the NXTR PM printer and NXTR A model pick and place machine, which are at the core of FUJI Smart Factory 2.0.

Update history

-

Exhibition special website was opened.

Footage of the exhibition floor

Movie

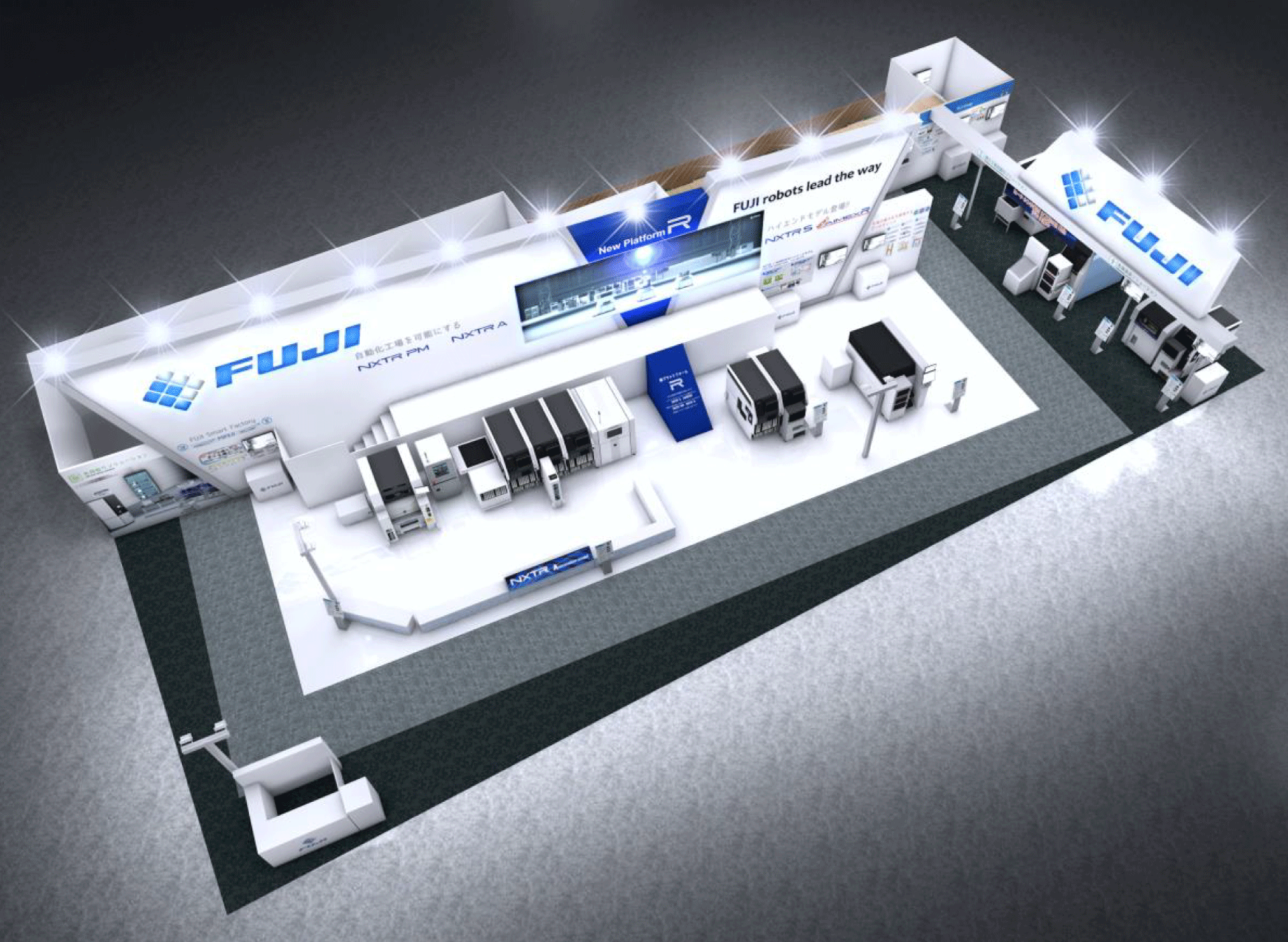

Booth layout

- 03 -

- 03 -Offline Changeover Solutions

FUJI Smart Factory - 06 -

System Solutions

Integrated Production System - Nexim - 04 -

Cutting-edge Automation Solutions

NXT III / GPX-CII - 02 -

Automation solutions

NXTR A model / NXTR PM - 01 -

Next Generation Placement Solutions

NXTR S model / AIMEXR - 05 -

Automated Solutions for Insertion Processes

sFAB-D / SW-BA

Exhibited product information

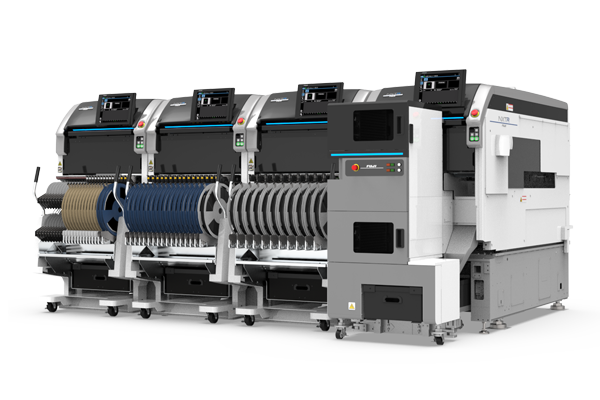

Next Generation Placement Solutions

Fuji will exhibit its latest SMT pick and place machines, which inherit the modular concept that is the hallmark of Fuji's pick and place machines and have been enhanced in terms of speed and quality.

NXTR S model

The latest in the NXT-series Fuji Scalable Placement Platform.

By thoroughly enhancing quality check functions and expanding the range of supported panel sizes, these machines support all types of panel production, from small panels used in mobile devices, to the large panels required for automotive and base stations.

AIMEXR

The latest in the AIMEX-series Fuji Flexible Placement Platform.

This next-evolution platform is equipped with state-of-the-art placement heads that cater to all types of production. It is particularly suited to ramping up new production and changeover work, as needs to be performed repeatedly for high-mix and variable-mix, variable-volume production.

Automation solutions

We have on show a state-of-the-art automated line that automatically changes and transfers feeders and screen masks, greatly reducing operator workloads.

In the exhibition hall, we will demonstrate automatic transfer of screen masks using PM Smart Changer together with an AMR, automatic exchange of screen masks by a PM Smart Changer, and automatic feeder exchange using the Smart Loader.

NXTR PM

This cutting-edge solder printer supports a wide range of panel sizes and screen mask sizes, and boasts excellent fine pattern printing capability.

Automatic exchange of screen masks, backup pins, and backup blocks, and automatic calculation of printing parameters, reduce the time and effort required for changeover, and also reduce the lead time for ramping-up production.

NXTR A model

This cutting-edge pick and place machine comes equipped with an automatic feeder exchange system.

The accompanying Smart Loader exchanges feeders automatically, freeing operators from changeover and supply work. The machine also has additional features that strengthen the ability to maintain high-quality and productivity.

Offline Changeover Solutions

Offline changeover work is intricate and time-consuming, as it involves a lot of work from checking out parts to setting up feeders, as well as having to perform all the required checks. In addition, this process is highly dependent on people, which means that work times vary depending on the skills of the workers.

During the exhibition we will introduce support units and systems that work to eliminate errors and variation in changeover work.

FUJI Smart Factory

Fuji works in alliance with other SMT equipment manufacturers to be able to provide customers with the best in automation and smart solutions.

FUJI Smart Factory members

SMT solutions that integrate systems and automation technology

FUJI Smart Factory pageMachine-to-machine communication standards

for smart factories that replaces SMEMA

introductory video

Cutting-edge Automation Solutions

NXT III

This high-speed multipurpose pick and place machine boasts the industry's highest level of area productivity.

At this year's event we will be exhibiting equipment configurations suitable for high-speed, high-density placement of ultra-small parts such as 0201 mm (008004") parts, which are increasingly being used in products; especially mobile devices.

Units on show

Automatic supply unit for bulk-supplied parts - Vibratory array feeder

Part replenishment without splicing - Auto Loading Feeder

GPX-CII

This is a superior cost performance printer that can cater to a wide range of panel sizes.

From small panels with fine patterns for 0201 mm (008004") parts, to large 610 x 610 mm panels, this machine delivers high-quality printing.

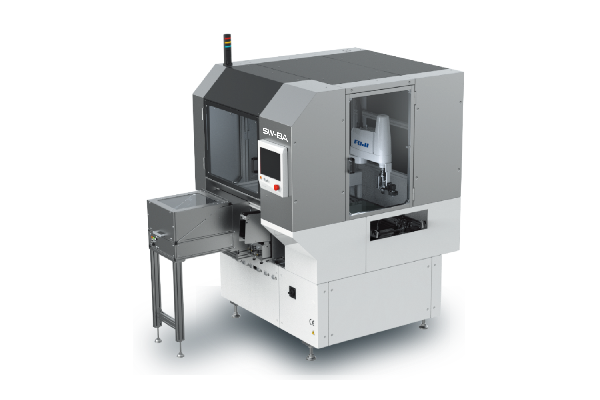

Automated Solutions for Insertion Processes

sFAB-D

This is a high-speed, high-accuracy insertion machine that supports large parts up to 200 x 200 mm lengthwise, and up to 75 mm in height.

With the highest level of supported part sizes in the industry, and supply units ready to support a wide variety of packaging types, this machine boasts an impressive automation rate.

Loadable units

Radial part supply unit - Radial tape feeder

Loose parts supply unit - BPU2

Lead correction unit

SW-BA

This is an insertion machine that uses a SCARA robot.

With a dual camera system, with one mounted on the base and the other on the end of the arm, it is possible to perform complex insertion and assembly operations.

We will perform demonstrations of inserting and arranging heat sink and diode parts during the exhibition.

System Solutions

Nexim

Integrated Production System - Nexim, the core of FUJI Smart Factory will be featured, along with demonstrations.

Software functions that are indispensable for production improvement will be introduced using three key words: "Non-stop," "Maintain," and "Reduce".

Our technical staff will be happy to answer any questions you may have about our software.

PROTEC Seminar

Our staff will be taking to the platform daily.

We will introduce the pick and place technology required for current and future panel production and the latest SMT floor automation solutions.

Note: Seminars are only available in Japanese.

Seminar venue: East Hall 5 entrance, exhibition organizer's office

Current position of FUJI Smart Factory 2.0

FUJI Smart Factory that maximizes production

We will introduce the full picture and the current position of FUJI Smart Factory 2.0 aiming further evolved automation and laver saving.

- Lecturer -

Robotic Solutions Division

ASP Project

Team Leader

Masataka Iwasaki

The latest surface mount technology for supporting connected societies

We will introduce the pick and place machine AIMEXR, which has been developed to realize stable production from NPI to mass production flexibly and at high speed.

- Lecturer -

Robotic Solutions Division

AIMEXR Project

Project Manager

Takayuki Mizuno

Sustainable manufacturing and surface mount technology trends as seen in automotive board assembly

Focusing on the automotive products that is driving the market expansion, we will introduce the key points to realize sustainable and stable manufacturing in response to the mounting trends that can be seen from the current situation.

- Lecturer -

Robotic Solutions Division

Sales Planning Department

Sachimaru Takeno

Note: There is a limit on the number of people who can participate. Be sure to register early to ensure that you do not miss out.

Exhibition booth information

Tokyo Big Sight (Tokyo International Exhibition Center)

East exhibition hall, east hall 5

Fuji booth number: 5F-07

Learn more about Fuji products

Visitor pre-registration