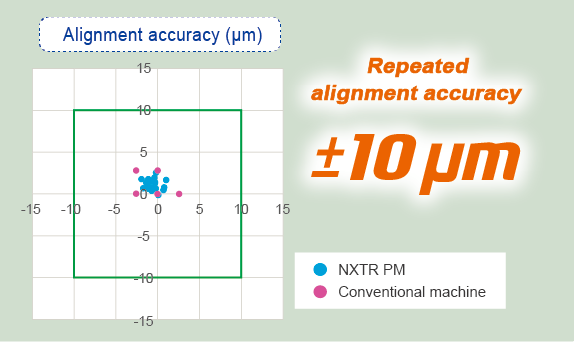

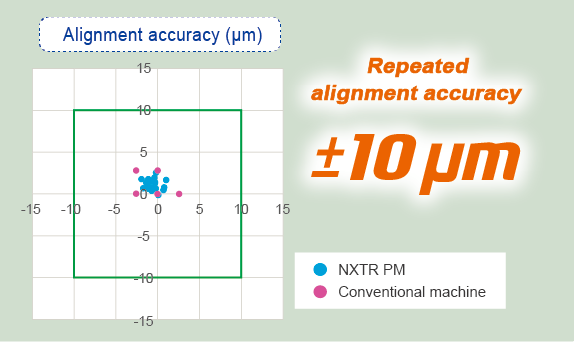

Repeated alignment accuracy ±10µm(6σ)

Better responsiveness to positioning the mask results from the lighter-weight offsetting mechanism with reduced sliding resistance in addition to advanced image recognition accuracy for fine marks that is driven by the high resolution camera.

This brings a high level of alignment performance with stable printing quality.

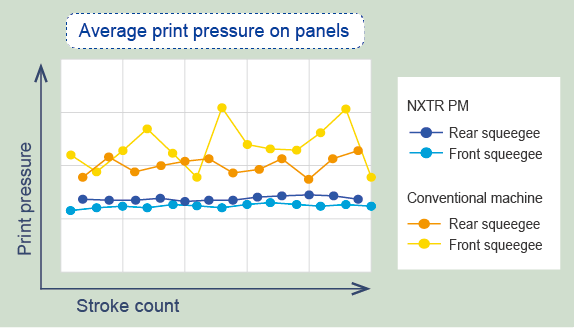

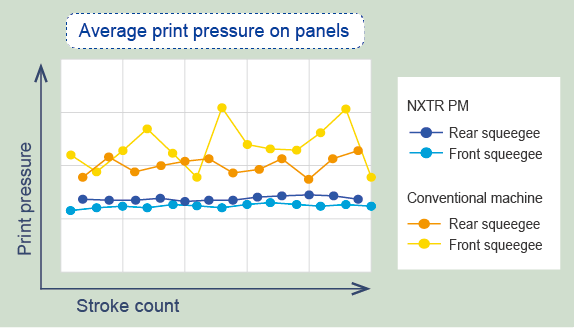

Using the appropriate print pressure

It is essential to apply the appropriate pressure to print the correct volume of solder. Our real-time print pressure feedback control and newly developed squeegee head stabilize the print pressure at all times and maintain the angle of the squeegee edge.

This ensures the correct volume of solder.

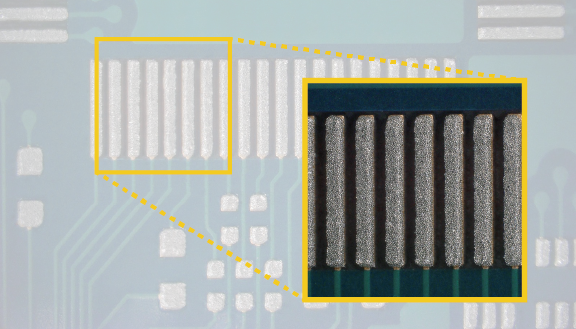

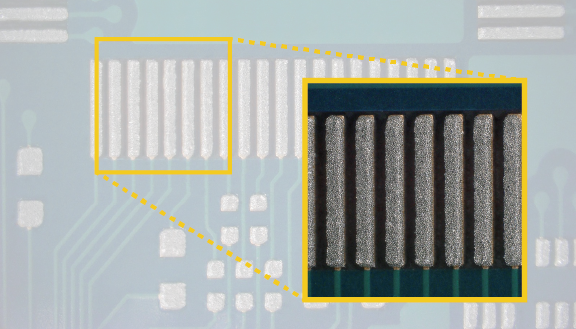

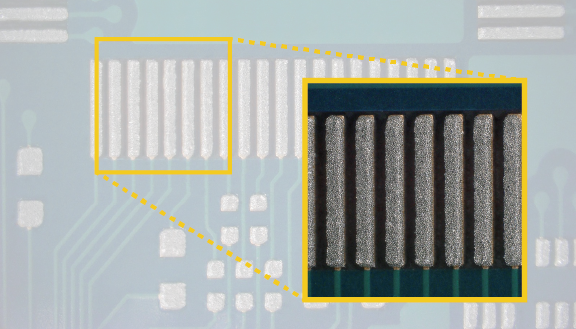

Printing shapes with sharp outlines

Taking into account the solder fluidity during snap-off, snap-off operation has optimized acceleration control.

This makes solder deposits in apertures transfer onto panels in the correct shape.

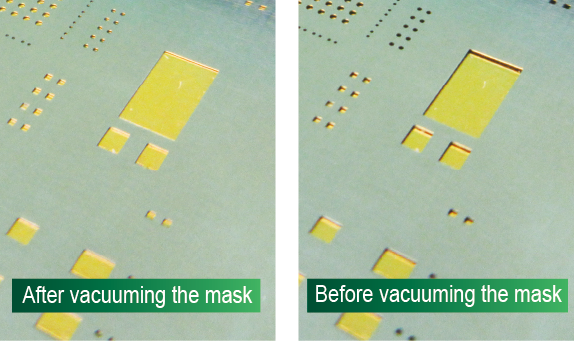

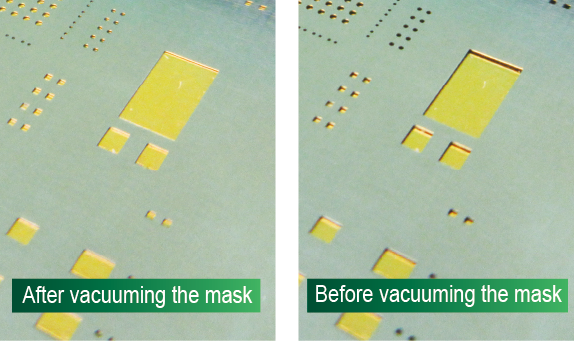

Reducing print deviations caused by stretched masks

The renewed vacuuming mechanism improves the panel and mask adhesion.

This eliminates print defects caused by stretched masks.

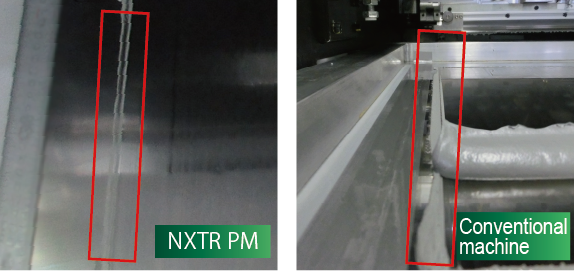

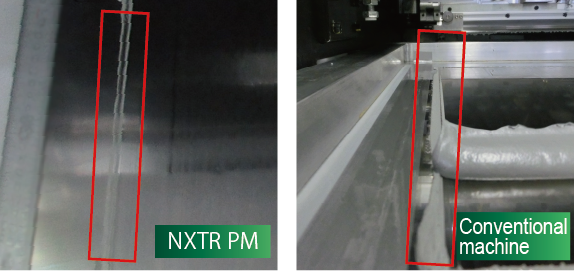

Preventing solder from escaping

The mechanism to reduce the amount of solder escaping from the printing squeegee lowers the volume of escaped solder substantially.

This leads to a higher rate of utilization of solder.

While this results in using fresh solder which furthers the stability of print quality, it also reduces solder collection and cleaning work.

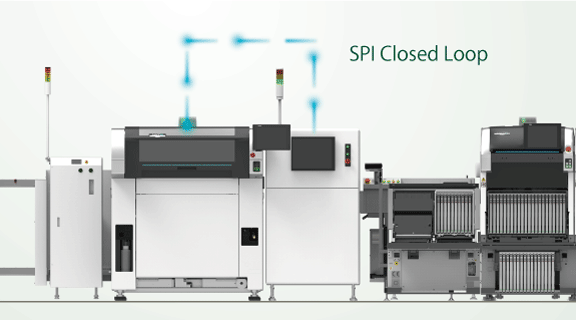

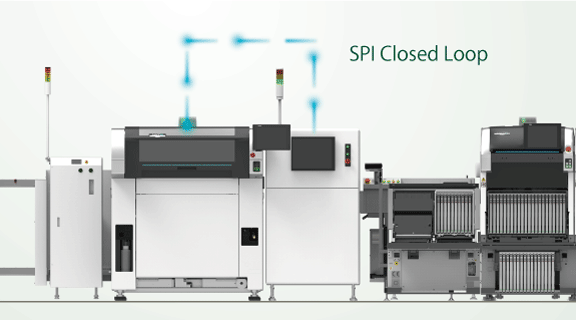

No line stops for quality-related errors

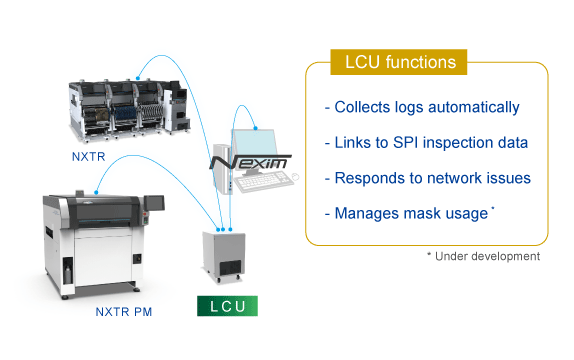

Based on inspection result feedback from SPI machines, automatic offsetting is implemented in the printing conditions based on a prediction of future printing problems such as solder volume deviations, misalignment, and smearing.

This helps maintain high quality printing.

* Option

- Automatic mask positioning adjustment

- Mask condition visualization by mark camera

- Solder supply instructions

- Automatic cleaning

- Automatic production stops