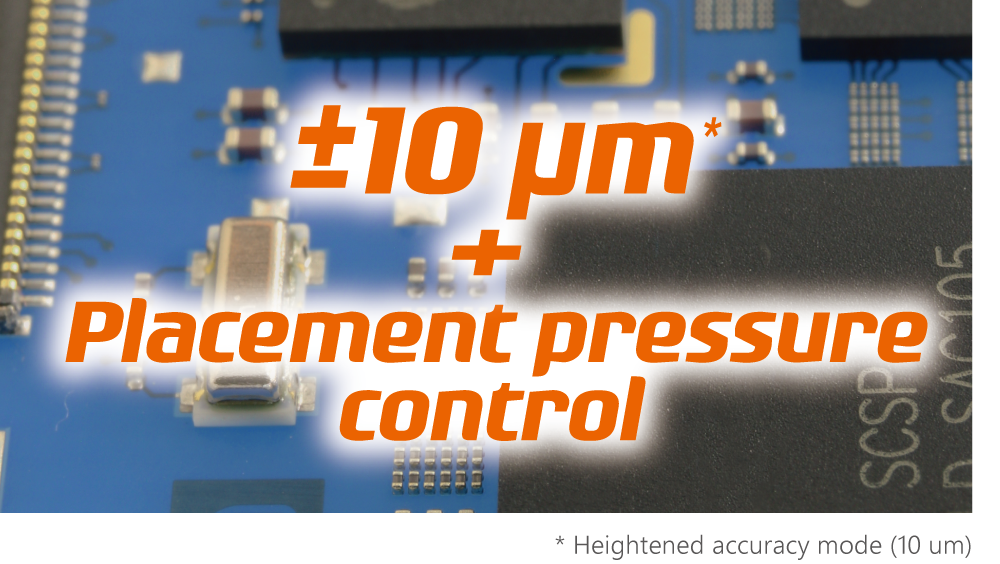

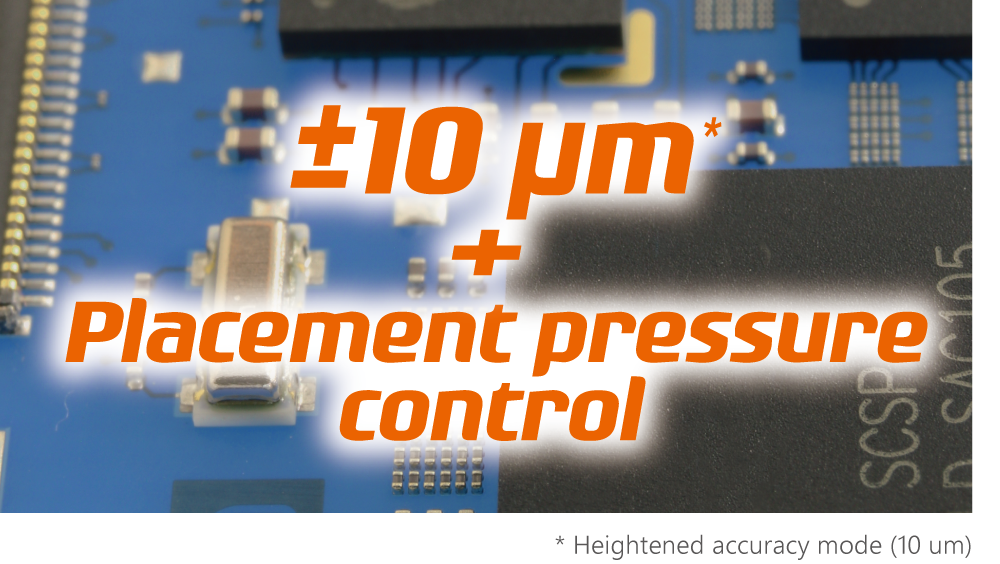

Offers high accuracy placement

Placements can be performed with an accuracy of ±25 µm at all times without constraints for the head type or the parts to be placed. For parts requiring higher accuracy, placement with an accuracy of ±10 µm is possible by using heightened accuracy mode.

Additionally, controlling the push-in amount during placement allows for placement with the appropriate pressure.

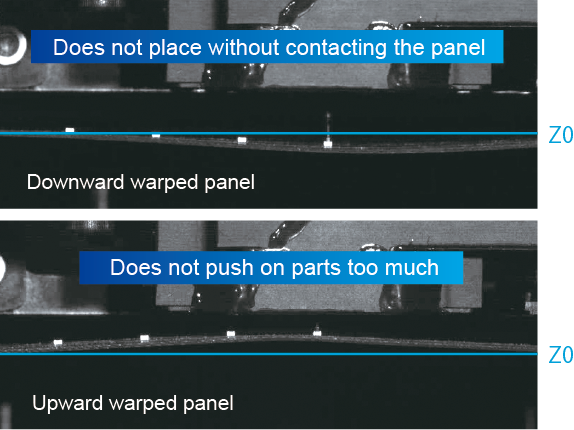

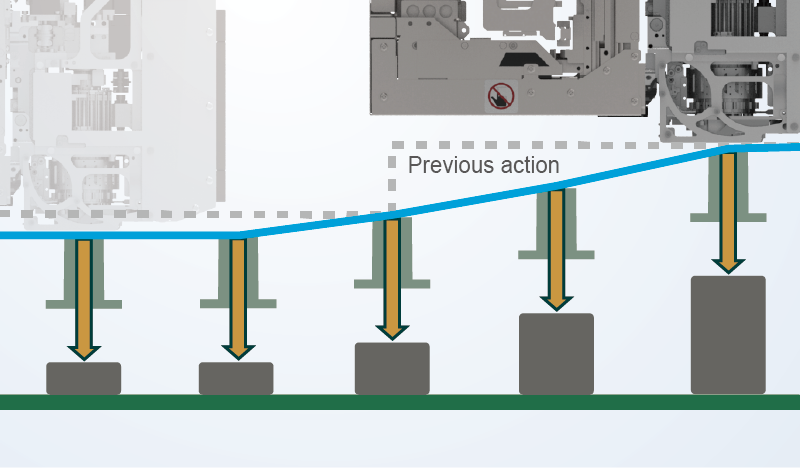

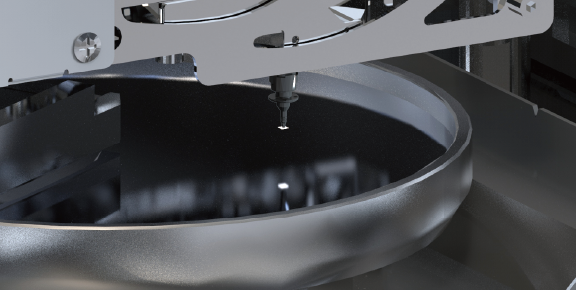

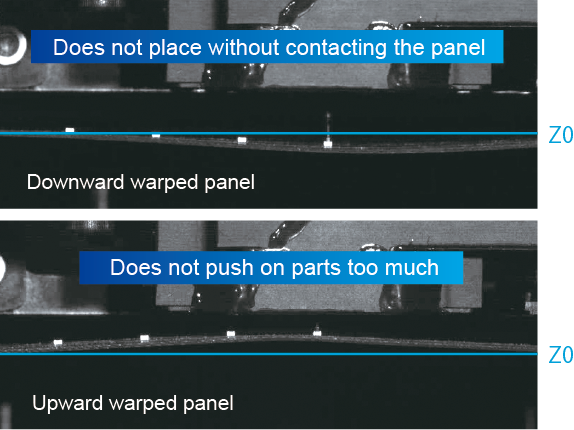

Places parts in a way that they are not affected by changes in the placement surface height

Adjusting the placement height

The placement stroke follows changes in the placement height due to panel warpage and distortions, which allows the machine to control the appropriate push-in amount and moreover prevents placement deviations and excess stress on parts and panels.

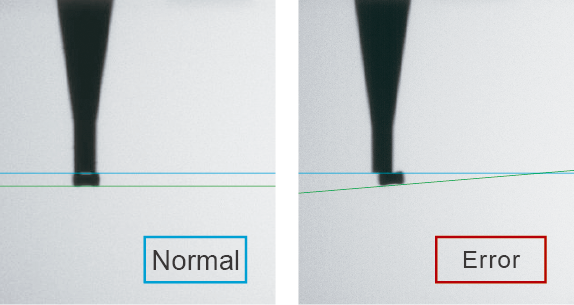

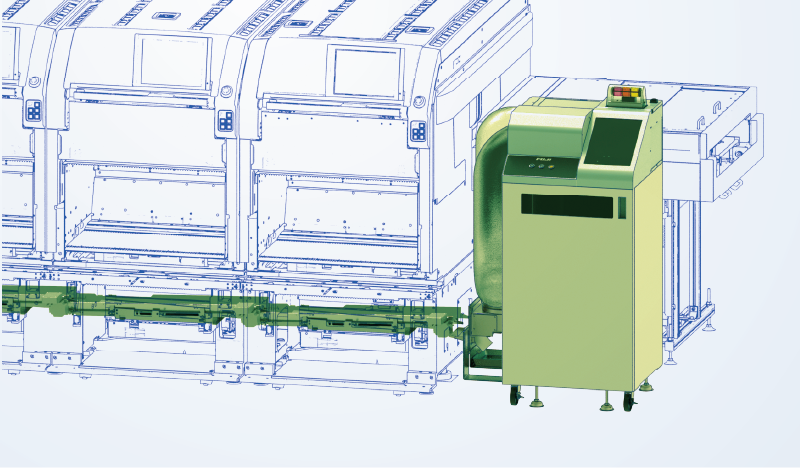

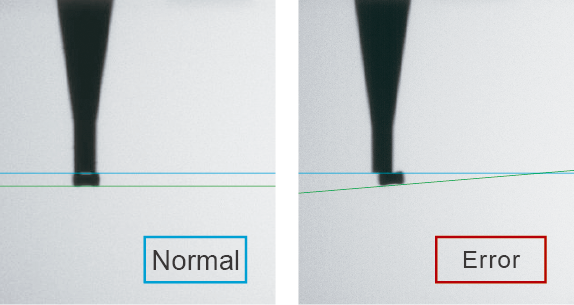

Checks placement within placement machines

Mark and parts inspection (MPI)

Various checks are available within placement machines to verify the process result shortly after that process: Checking placement immediately following placement, and checking placed parts before placing shield parts, for example. This prevents production of defective products and reduces wasted time and parts.

- Part presence check

- Misaligned placement check

- Part direction check (Under development)

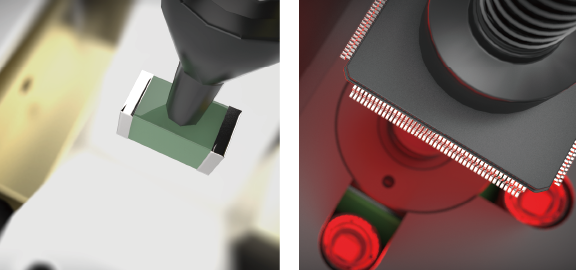

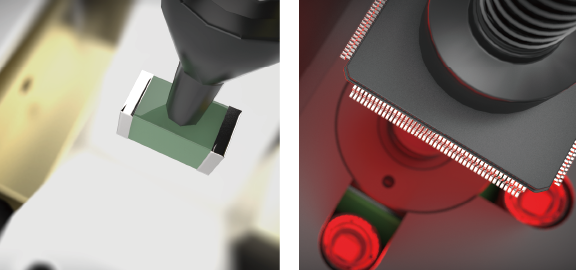

Checks for tombstoned, missing, and upside-down parts

Intelligent parts sensor (IPS)

The installed IPS system can cater to a wide range of checks, from part pickup stance to parts remaining on nozzles, as well as upside-down checks for minimold parts.

It prevents placement defects attributed to packaging, nozzles, and parts.

- Check for dropped parts

- Check of the part height

- Check for parts presence

- Check for parts remaining on nozzle

- Check for stuck nozzles

Prevents defects associated with part properties

LCR check, 3D coplanarity check

Placement defects caused by operation errors and defective parts are prevented by checking the electrical properties of chip parts with LCR checks and by checking the leads and bumps on IC parts with coplanarity checks. (Option)

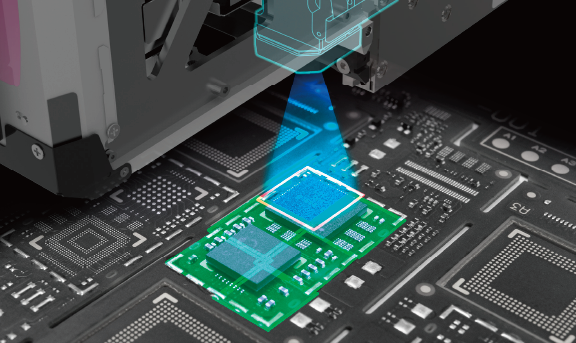

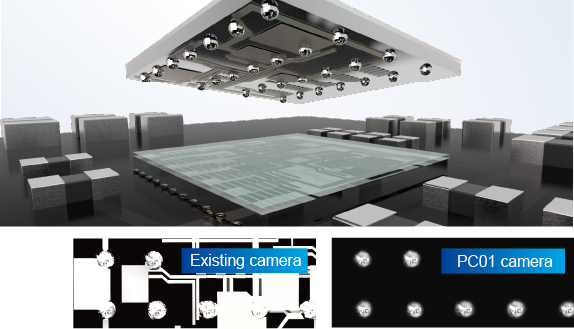

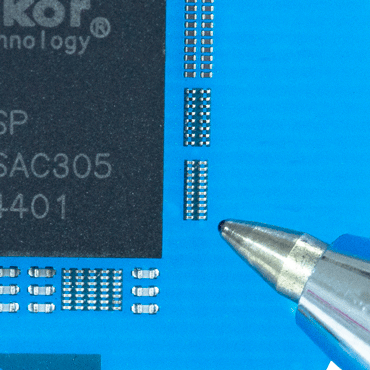

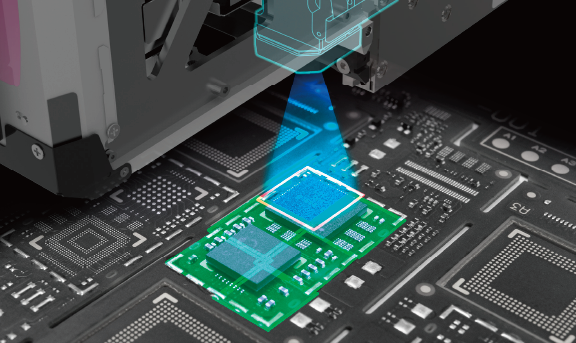

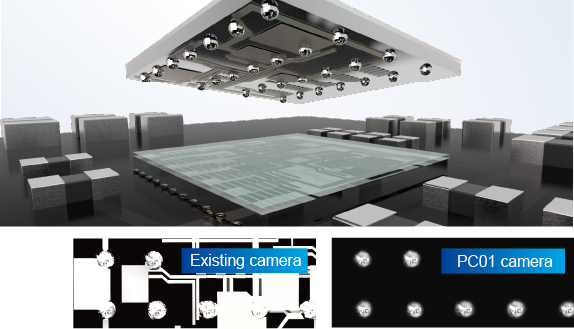

Places WL-CSPs with high accuracy

The camera equipped with advanced lighting technology, ensures reliable vision processing of WL-CSPs and other parts for which the background of parts are likely to be captured in acquired images. Using a high-resolution camera enables reliable recognition of bumps as small as 45 µm in diameter. This results in high accuracy placement.