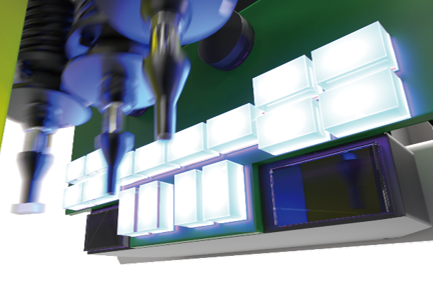

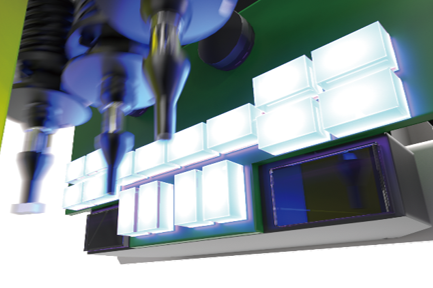

Checks tombstoned parts, missing parts, and upside-down parts

A wide range of checks like the following can be performed using the Intelligent Part Sensor (IPS).

· Checks pickup and checks for parts remaining on the nozzle after placement

· Detects tombstoned parts

· Checks part heights

· Checks for upside-down leaded parts

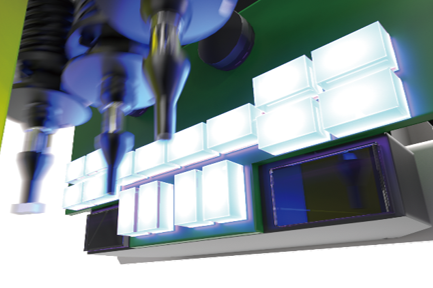

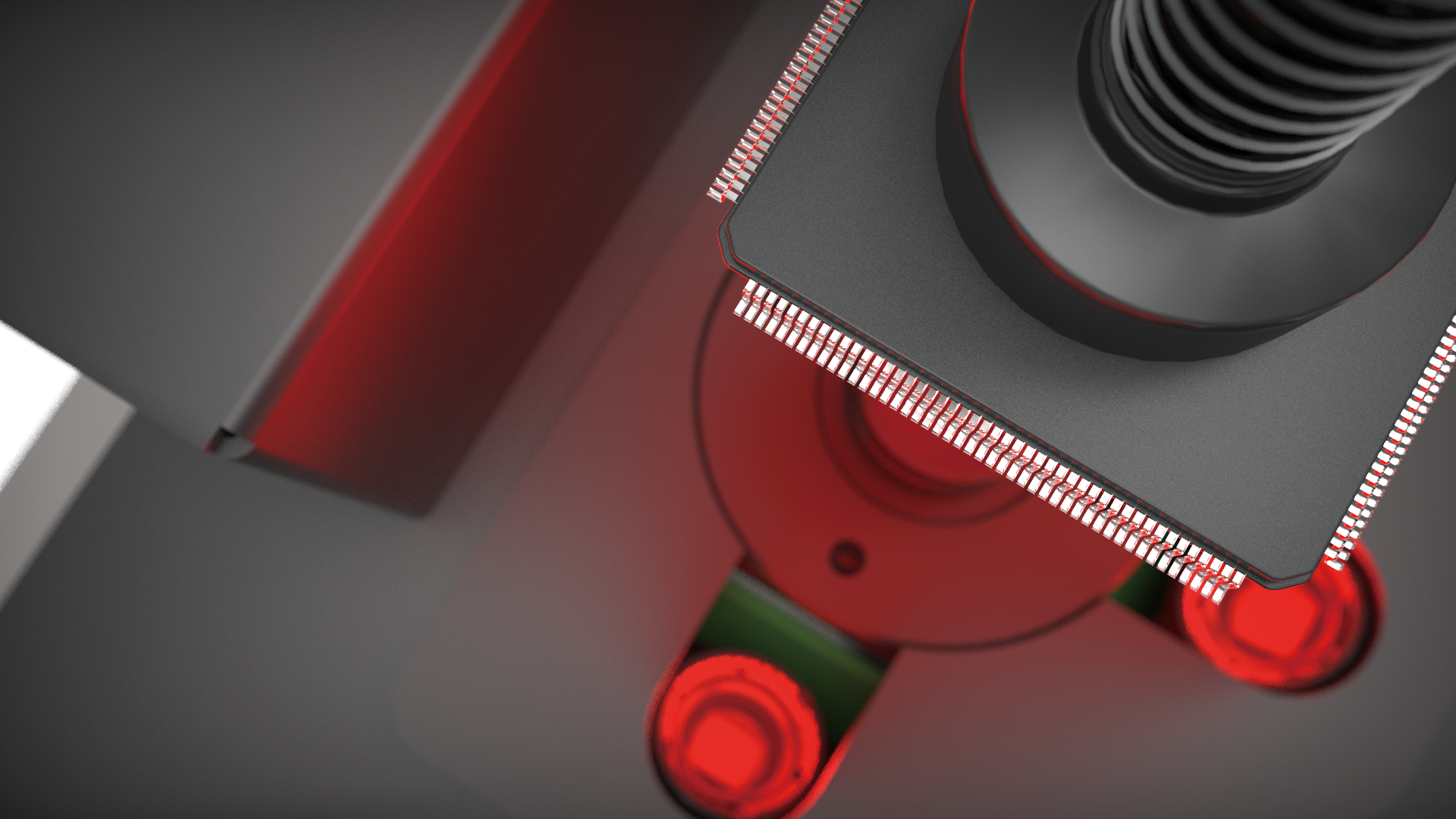

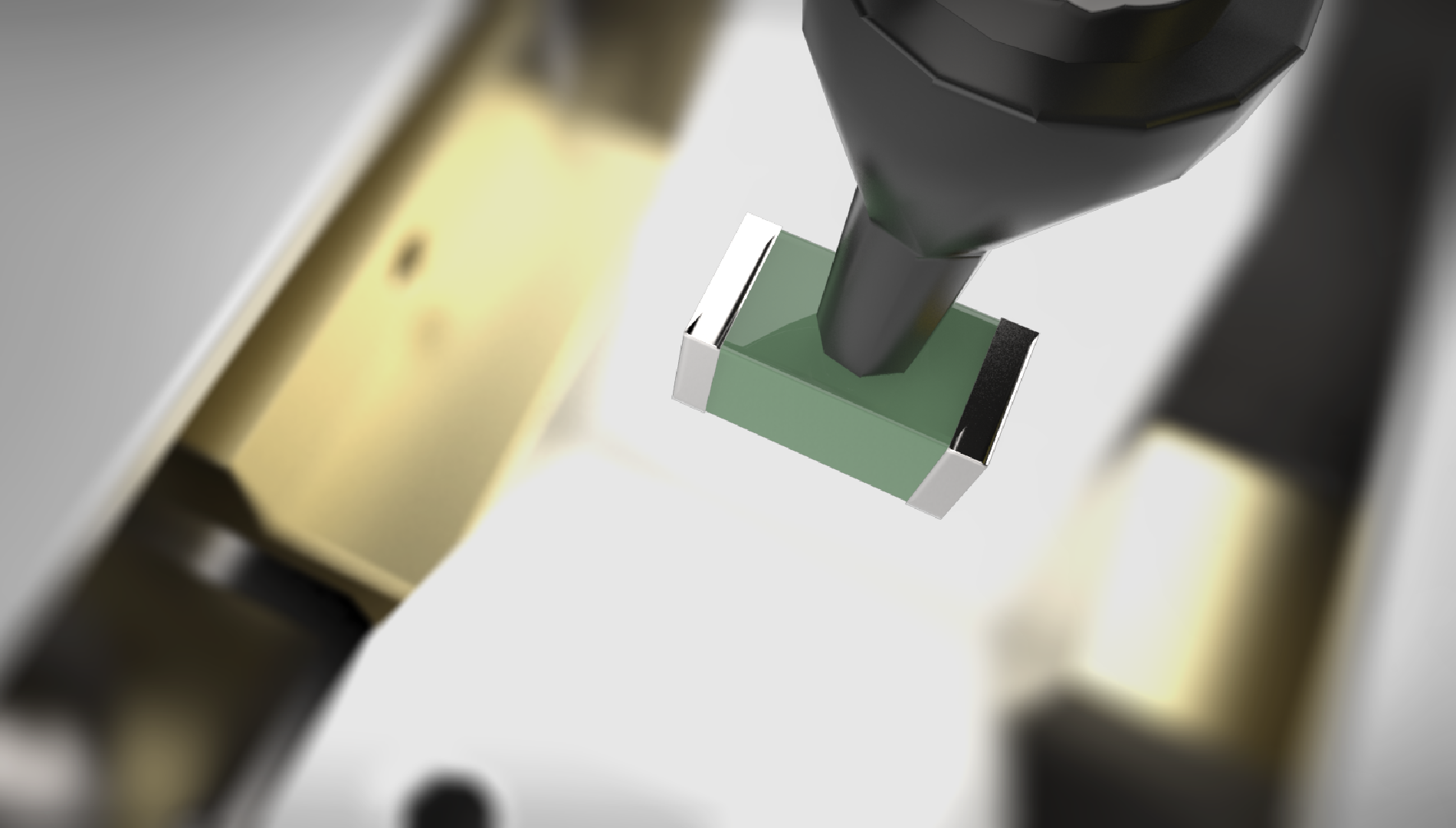

Electrical property checks (LCR checks) of chip parts

The LCR check unit checks the electrical properties of passive parts (inductance coils, capacitors, and resistors) before placement. This prevents parts with the wrong properties from being placed, which cannot be checked based on exterior checks.

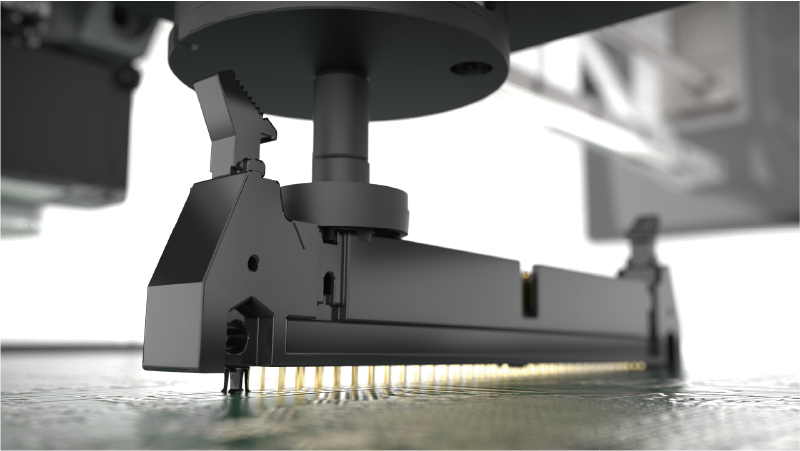

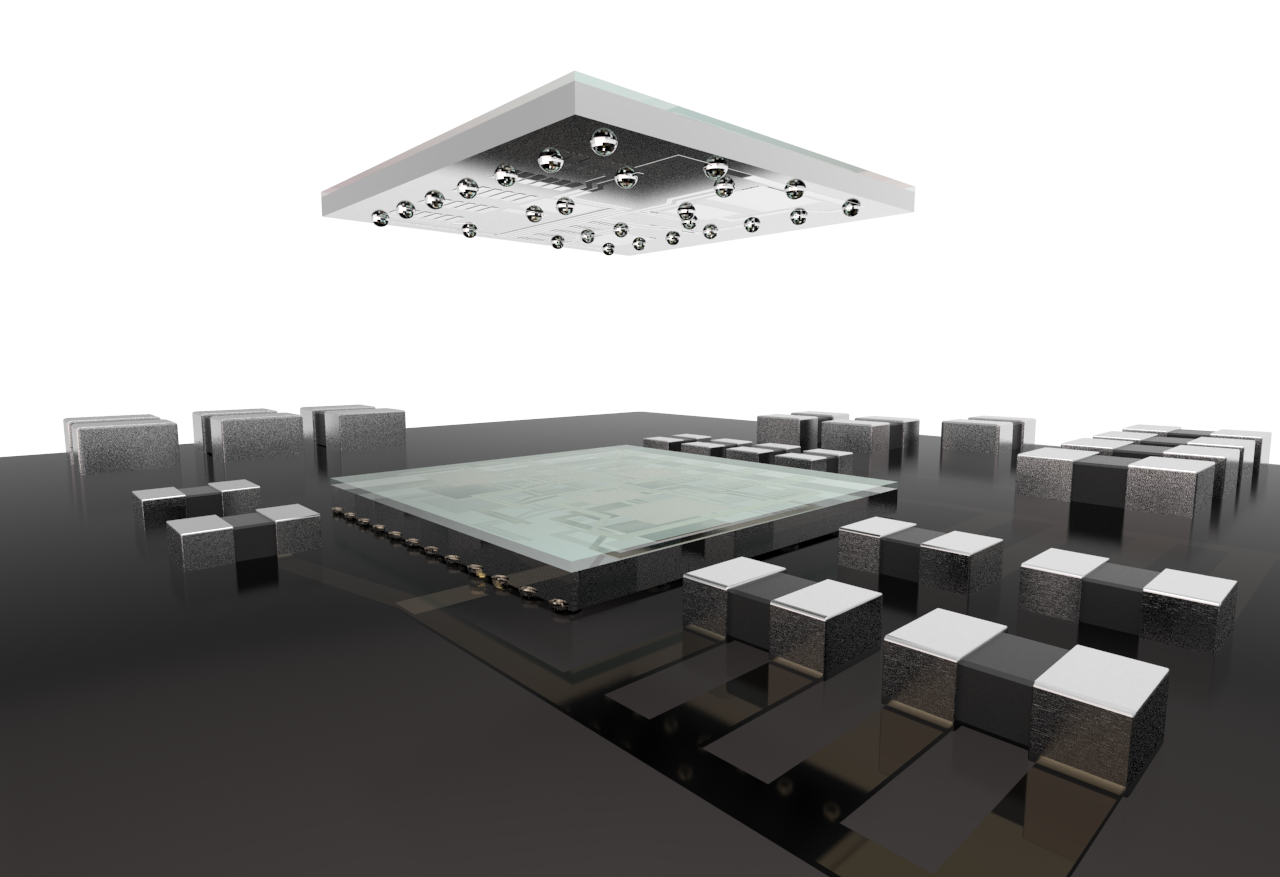

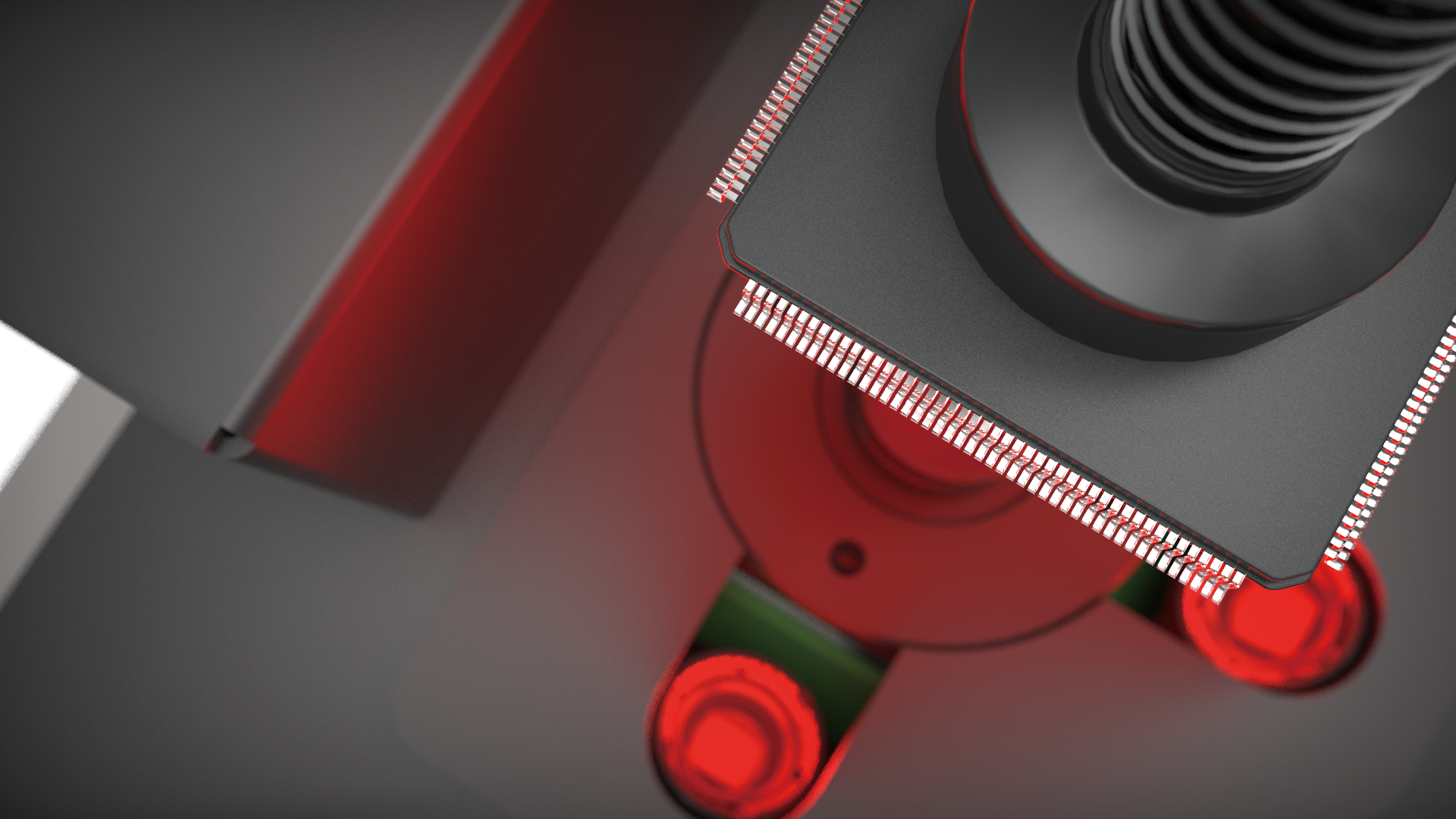

3D Coplanarity check that removes faulty parts

All parts are checked before placement to ensure that there are no warped terminals or leads on parts such as connectors and IC chips that can cause poor connectivity, preventing defective parts from being used. It is also possible to check for missing bumps on BGA and CSP parts, which cannot be detected after a part is placed.

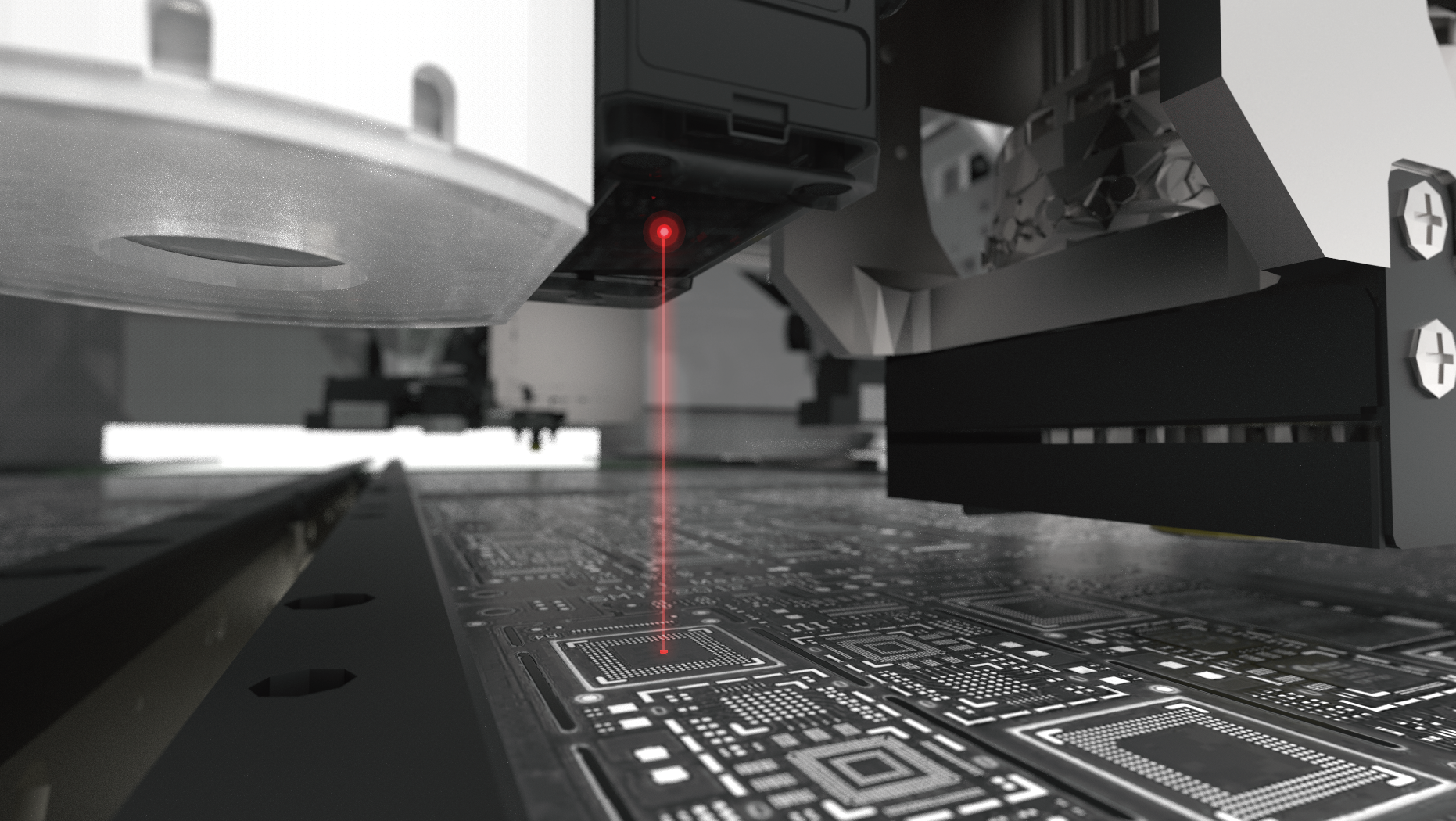

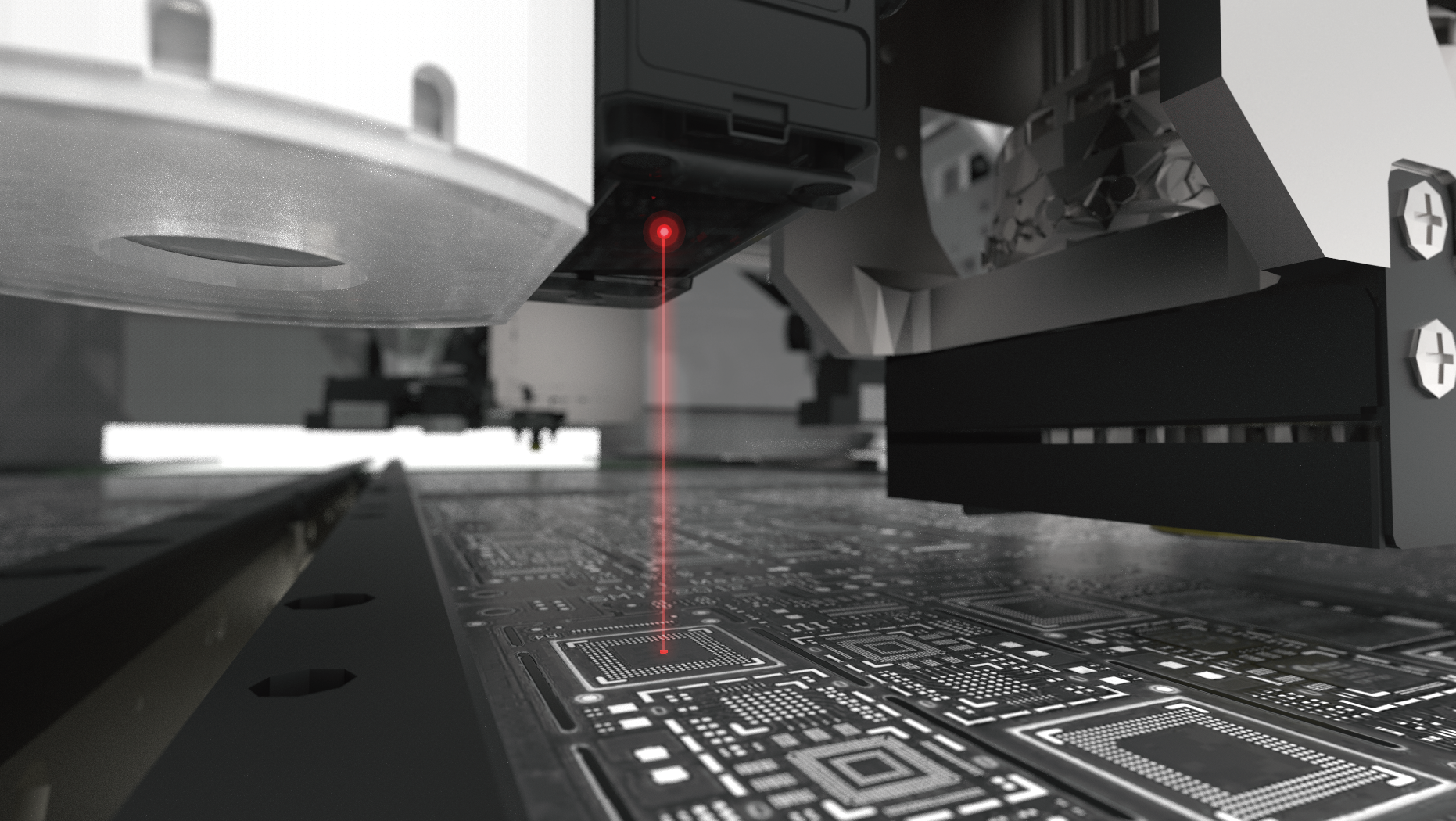

Panel warpage check

The panel warp is automatically measured by a laser sensor before placement. Placement is only performed on panels that are within the set tolerance, so that defective panels are stopped before they can be produced.

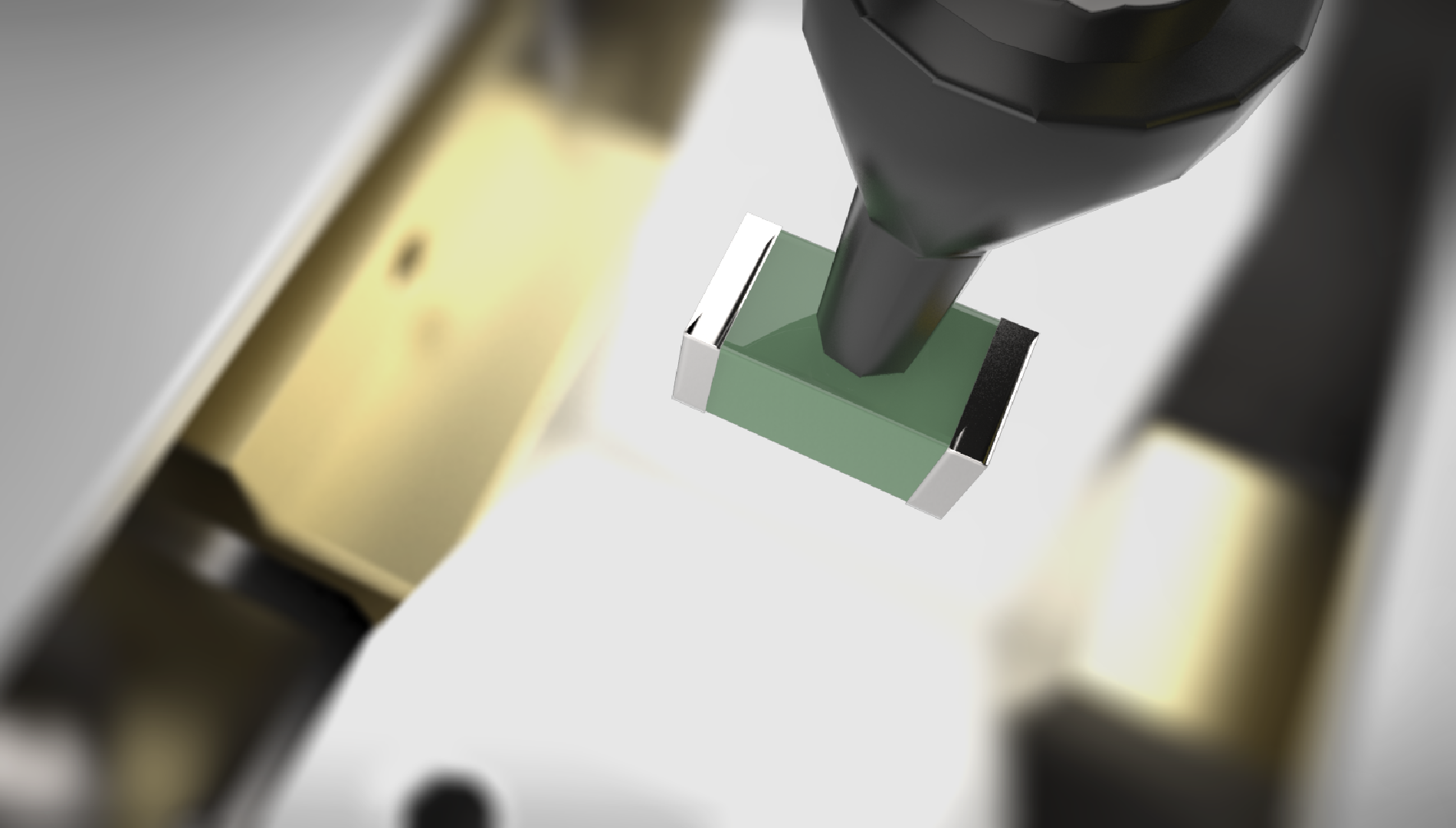

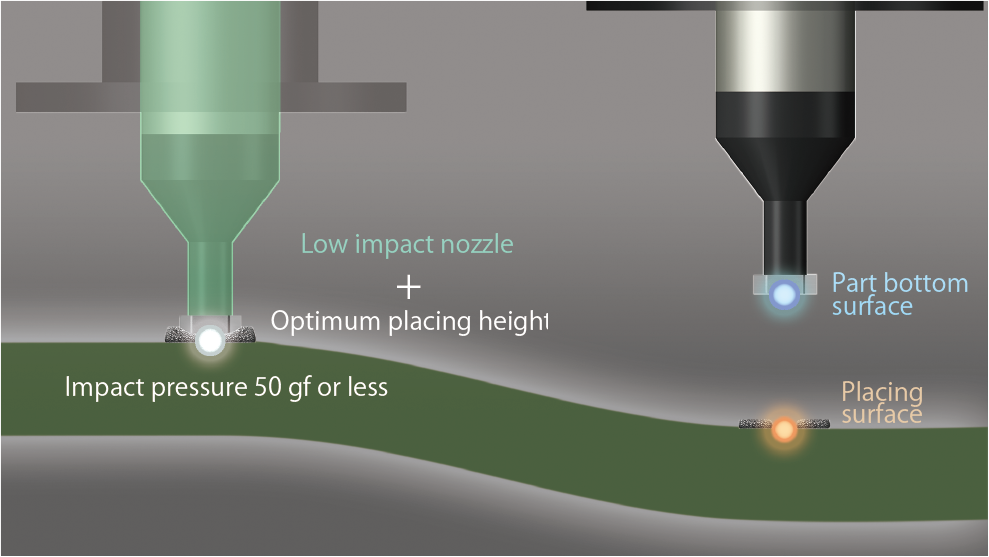

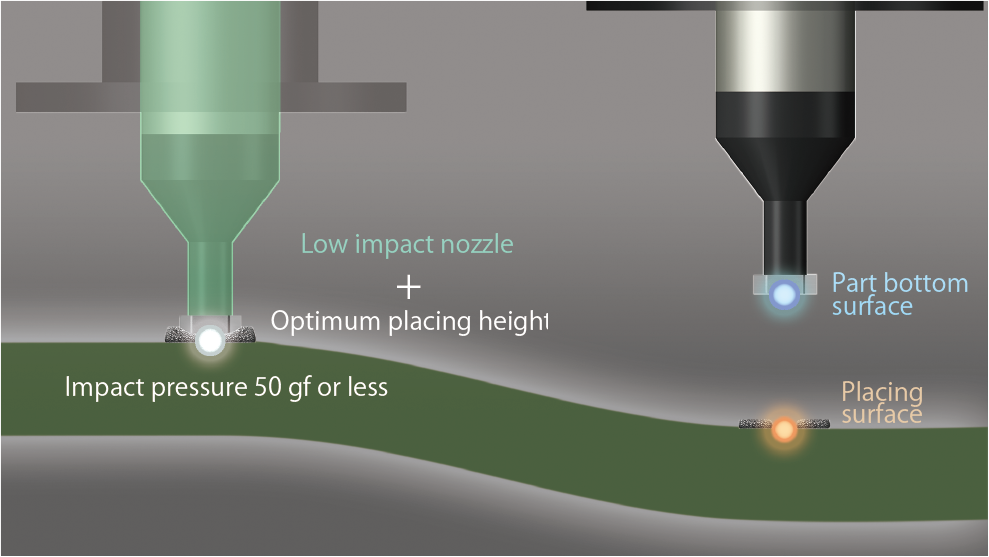

Low impact placement

Excessive downward push and placing parts above the panel can be prevented by reflecting the part height measured by IPS to the placing surface determined from the amount of panel warpage.

Furthermore, the low impact nozzle of Fuji's original design can prevent the collapse of solder and parts from becoming cracked.

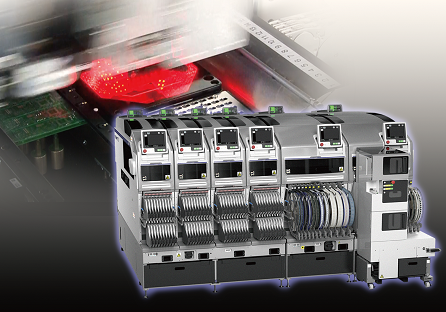

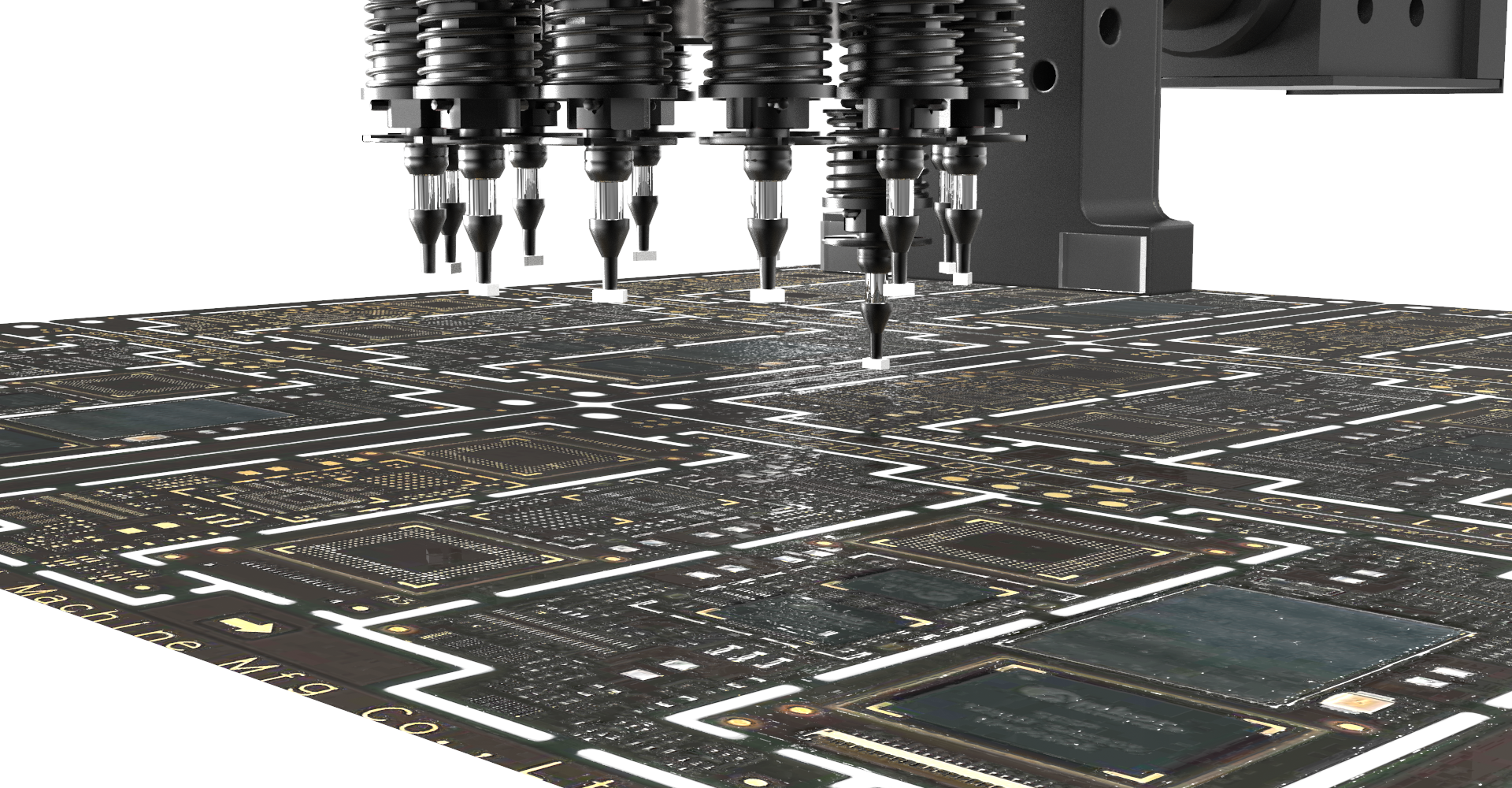

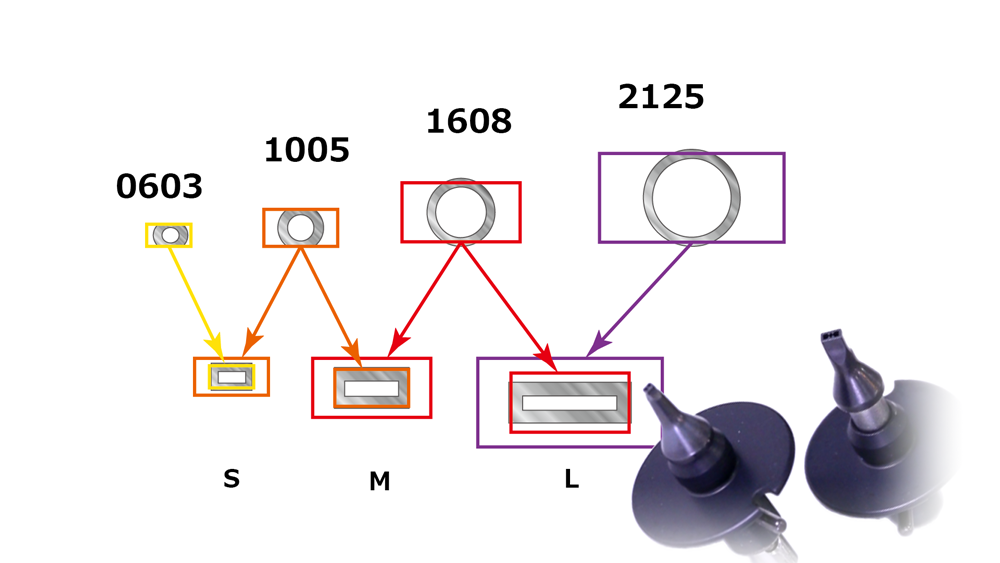

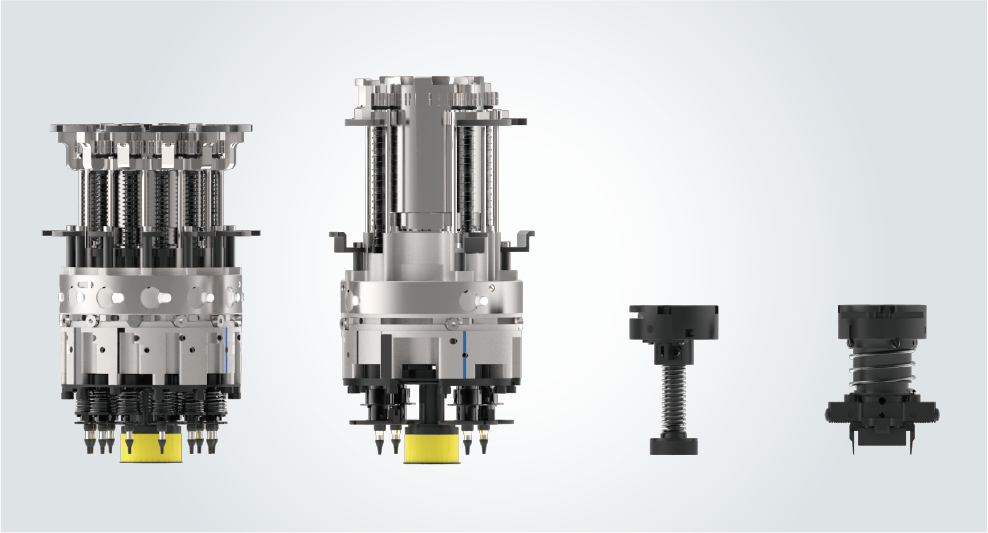

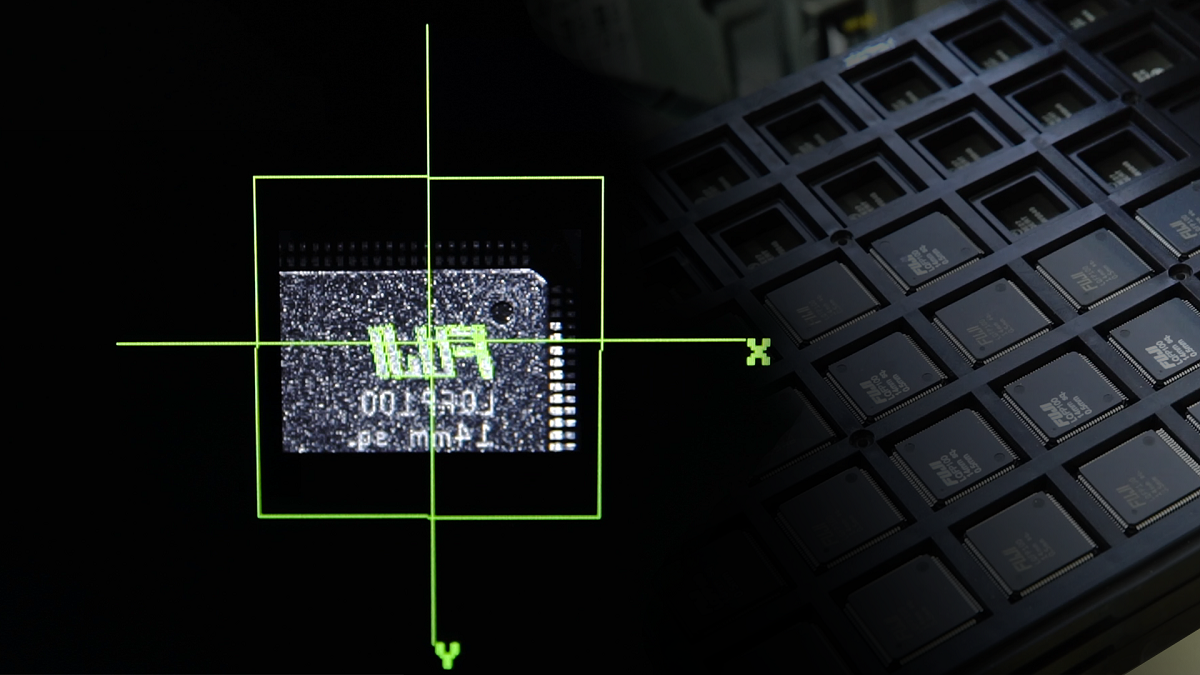

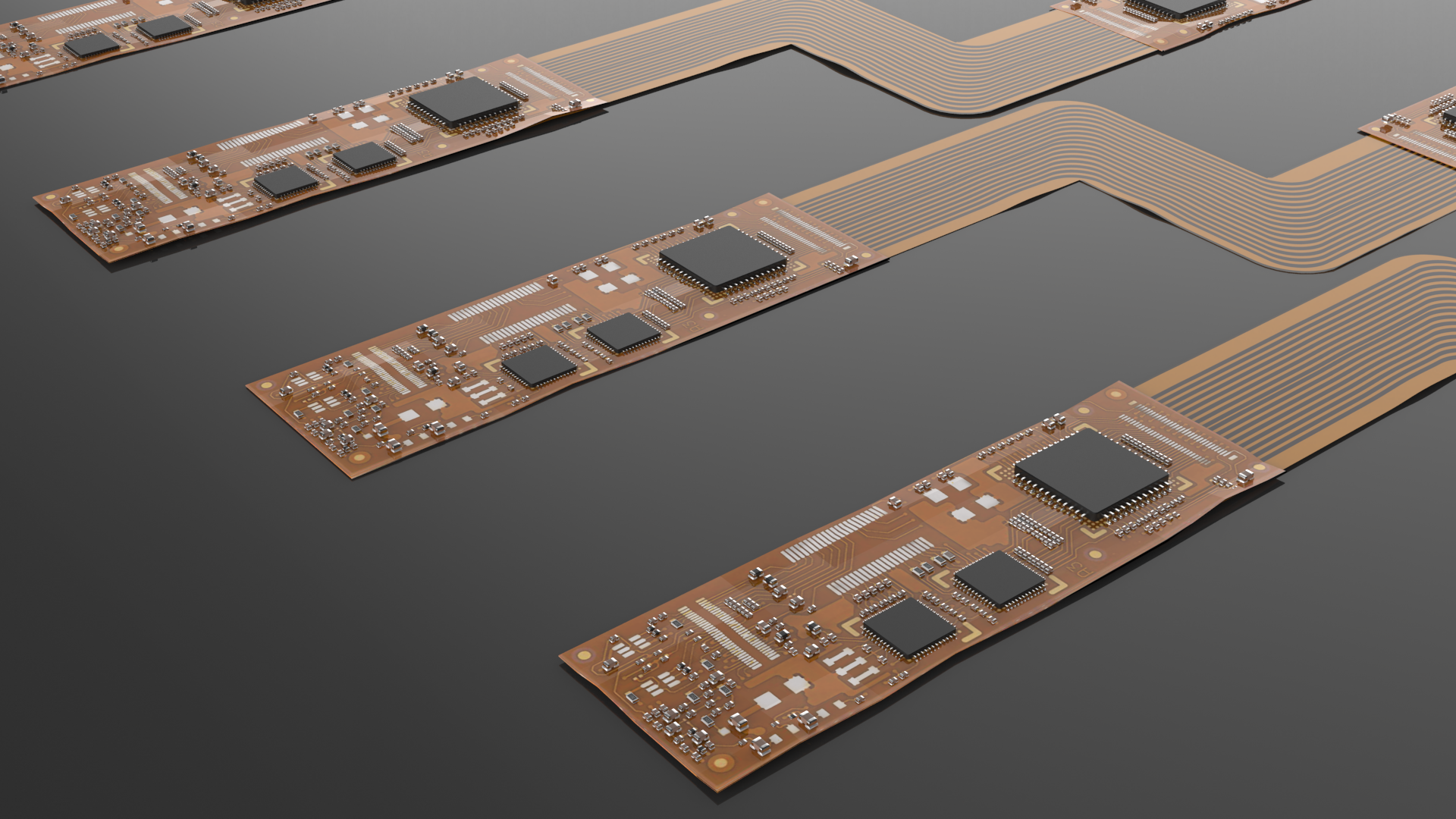

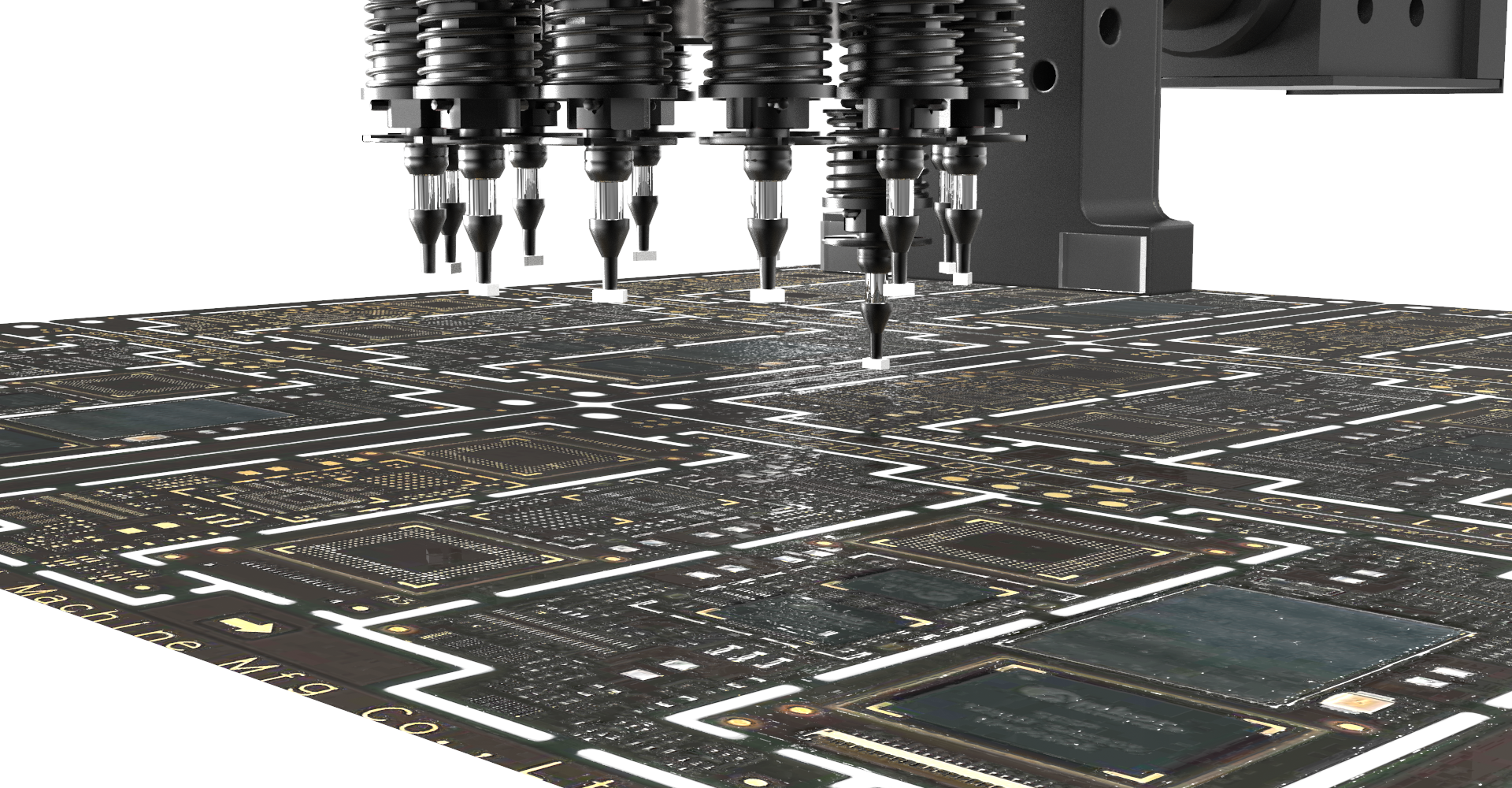

High quality, high density placement at top speed

Very high density part placement of 0201 (008004") parts is supported by standard specification cameras and units. Positioning is corrected as each part following pickup, so that very small parts can be placed with fine pitches at top speed.