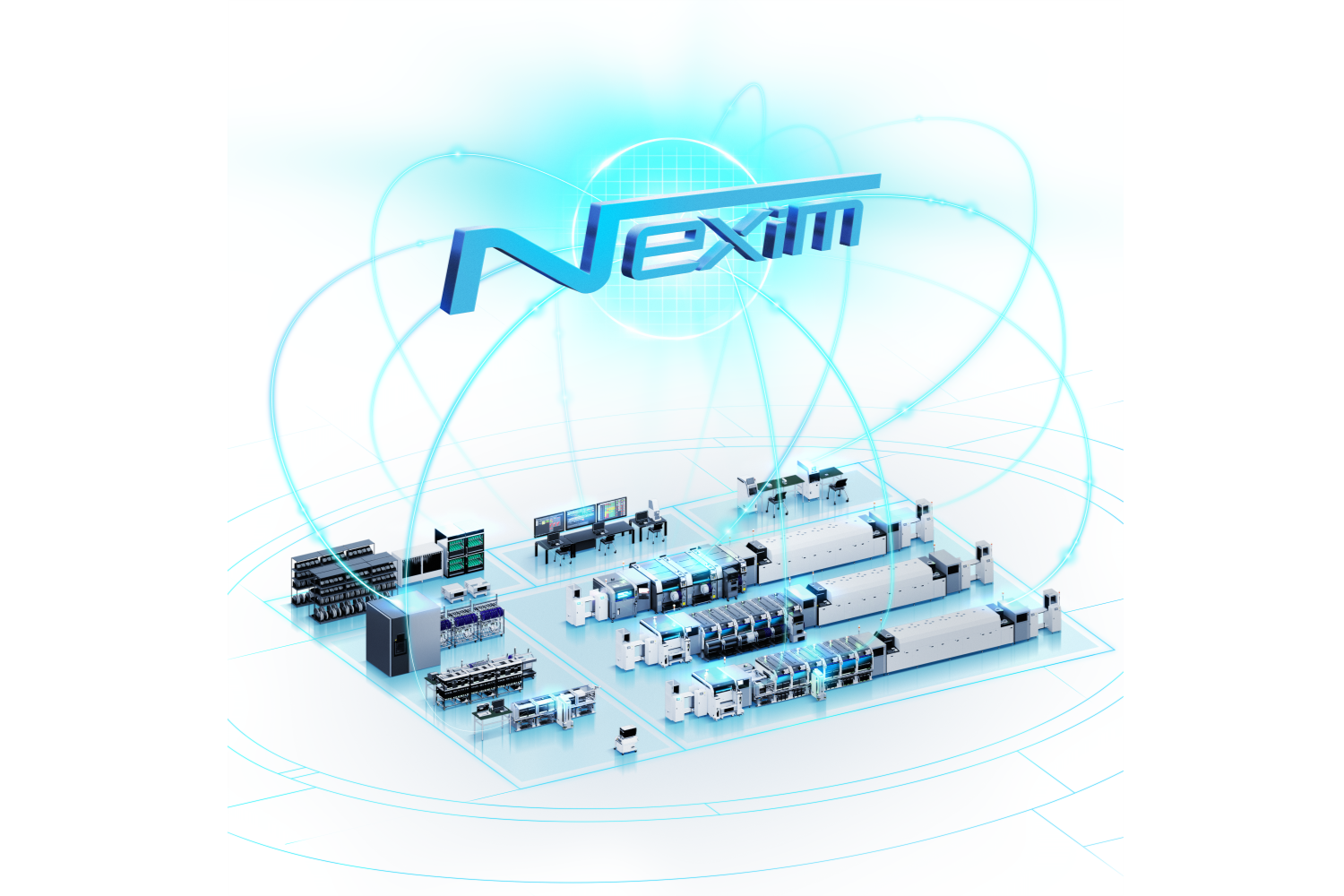

Mobile devices are evolving to be smaller and more advanced. Along with the spread of mobile devices worldwide and the increase in their production volume, more efficient production of mobile devices is necessary.

Fuji is continuing to develop and provide machines, functions, and systems to satisfy customer needs in every aspect including quality, productivity, and advanced placement technology.

50 gf placement impact force

Fuji machines can detect the panel and part heights and then place at the optimum placing height.

In addition, even with a placing speed of 100%, parts can be placed with a force of around 50 gf (approx. 50 gf when placing 0402 (01005") parts), which is among the best in the world.

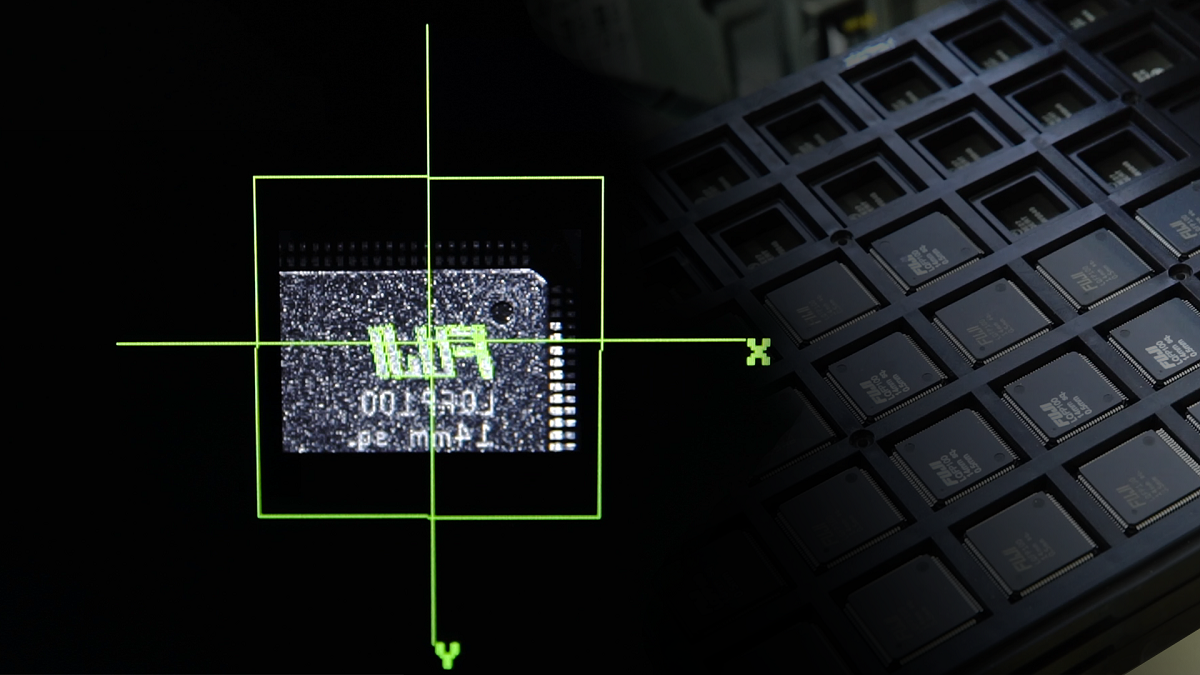

The presence of parts, the part's stance, and parts remaining on the nozzle after placement immediately before and after pickup and placement all can be detected for reliable placement.

Eliminates defects and catches causes of defects

Fuji machines make quality products in the production stage so defective products are not passed to later stages.

The part misplacement prevention system, the lead and bump defect detection system, and the part electrical check system ensure that defective parts are not placed.

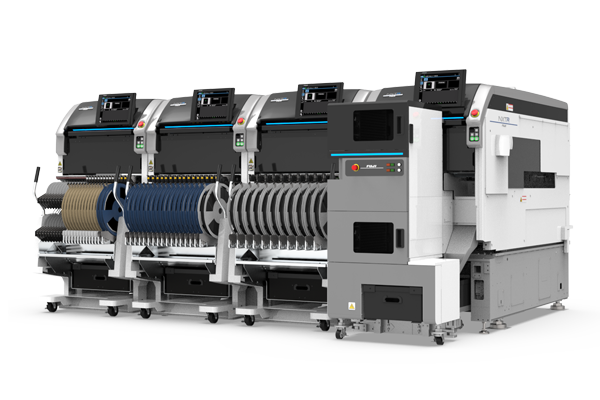

High area productivity

Fuji's placement machines, which encapsulate advanced performance in a compact body, make the most use of limited floor space. Compact modules mean that equipment can be added to meet your exact production requirements such as in production ability and floorspace.

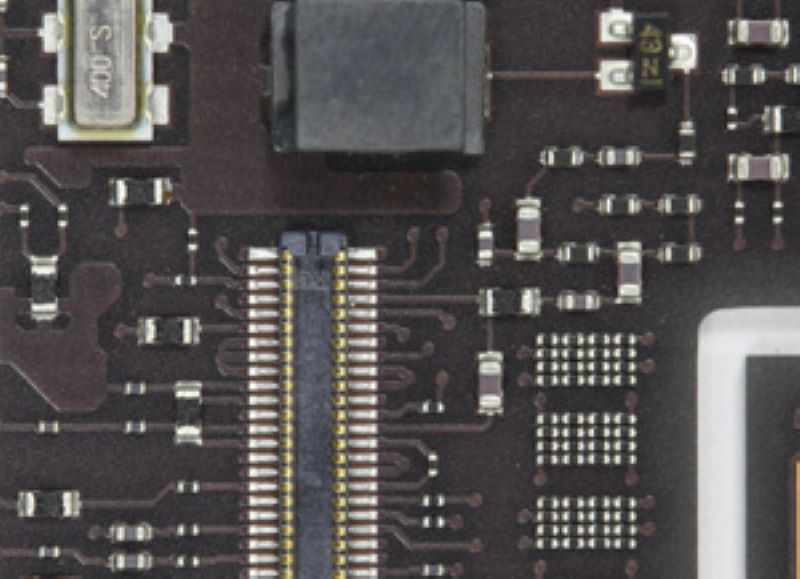

Very small parts placement

Smaller products with higher functionality require high-density placements with small parts on the assembled electronic circuit boards. Fuji's machines allow high-speed placement without having to change the speed even when placing small parts such as 0201 mm (008004") parts. We have achieved top class productivity in the industry.

Traceability

By linking the IDs used to manage the equipment that is thoroughly modularized and unitized to the placement data managed by individual references, it is possible to acquire detailed traceability data. This traceability data can be used to identify the related parts, machines, and units used for a particular panel ID or to identify the panels on which a particular part ID was placed.