- Automatic maintenance unit

- Automation

- Efficiency

- Labor-saving

- Maintenance

- Peripheral equipment

- Quality

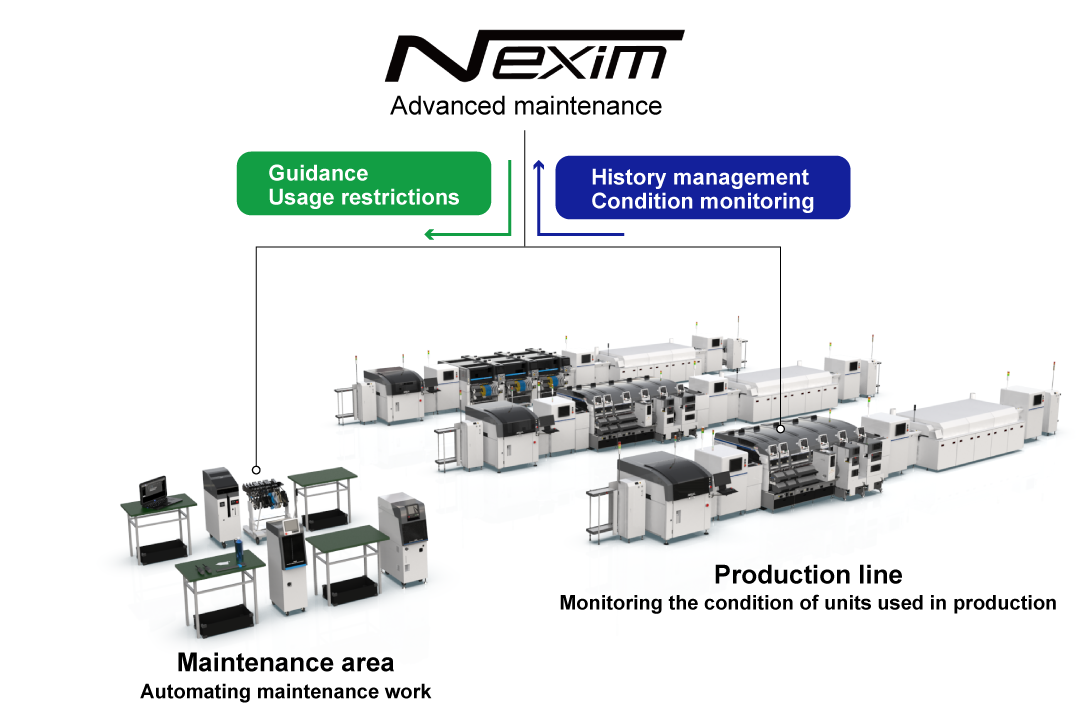

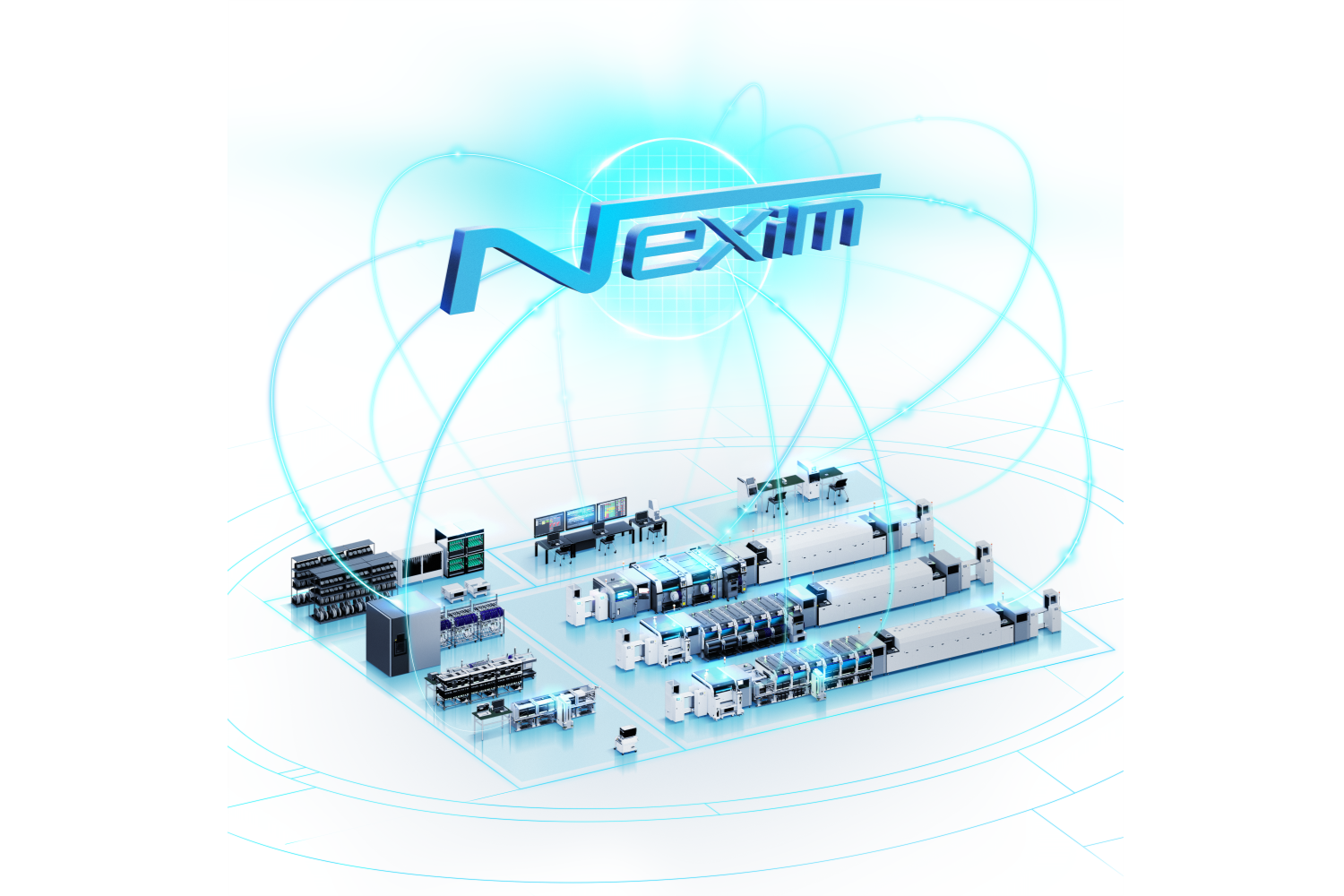

- Smart factory initiative

Easy and reliable head maintenance. No training required

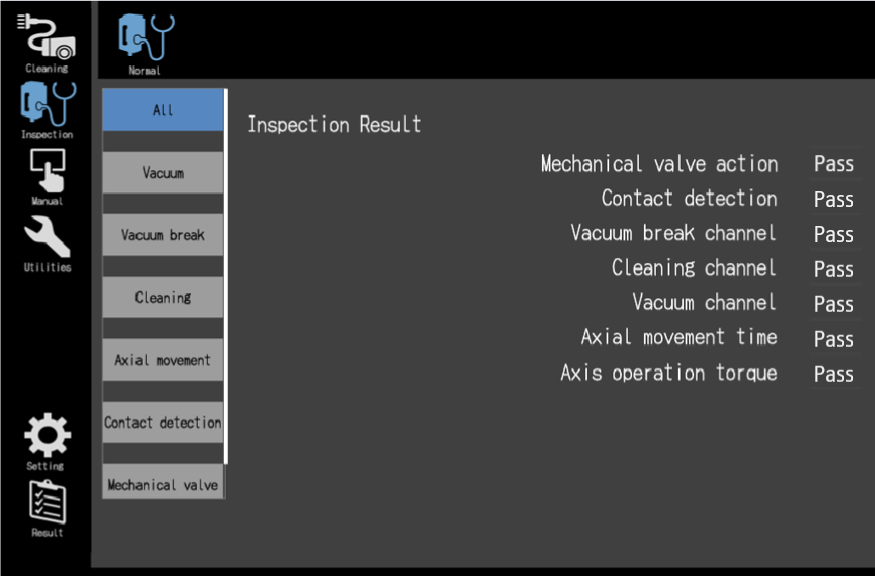

Automatically cleans and performs a series of maintenance tasks including cleaning the air channels inside the head and inspections.

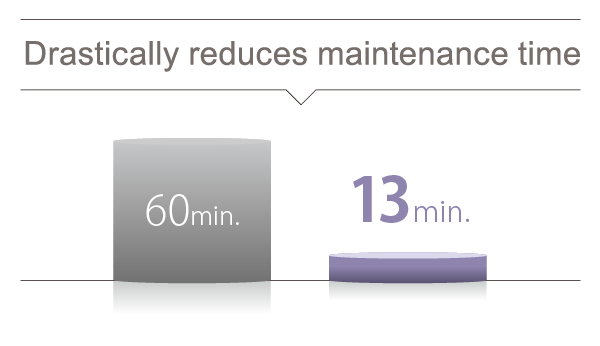

Maintenance quality is more stable and work time can be significantly reduced, compared with manual work.

Accurately diagnoses the condition of heads with the enhanced inspection functions.