- Automatic maintenance unit

- Automation

- Efficiency

- Labor-saving

- Maintenance

- Peripheral equipment

- Quality

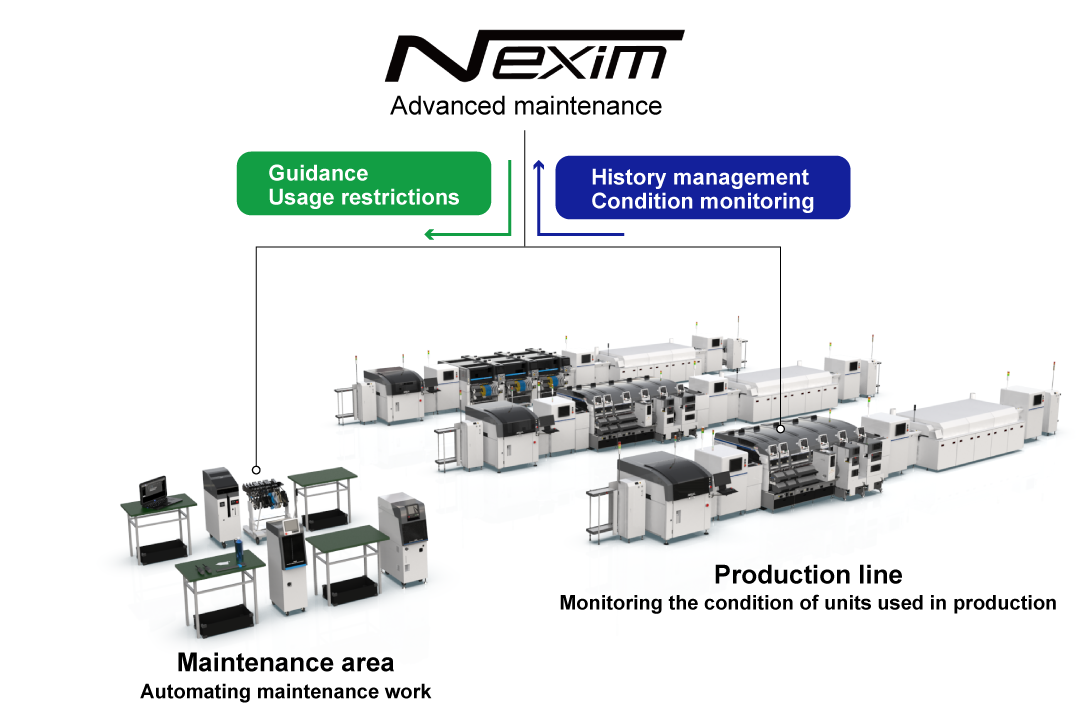

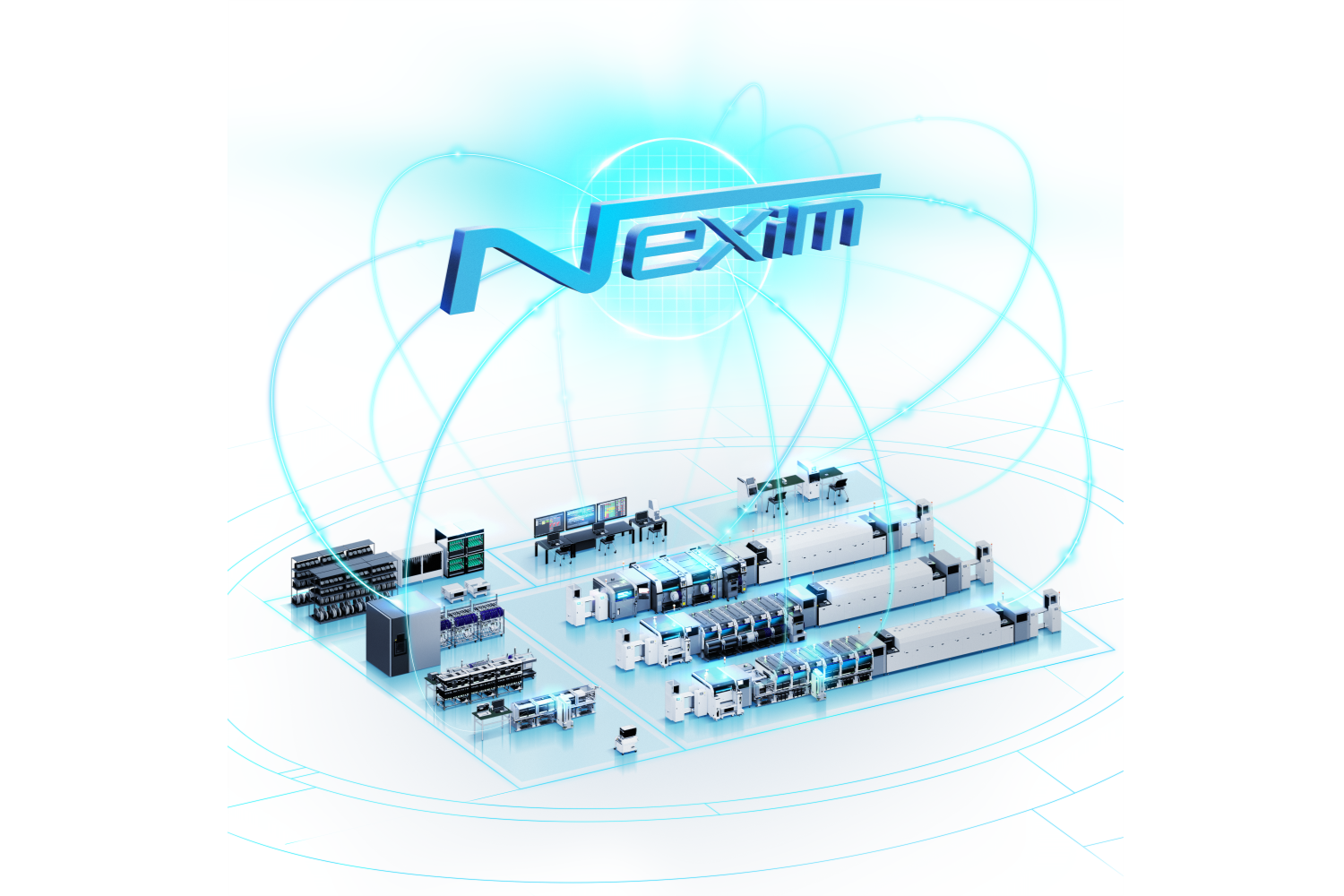

- Smart factory initiative

Easy and reliable head maintenance. No training required

Automatically cleans and performs a series of maintenance tasks including cleaning the air channels inside the head and inspections.

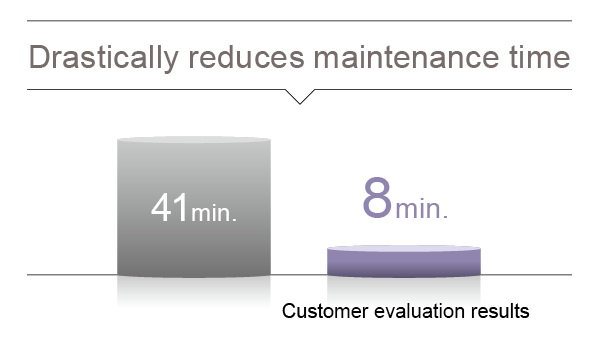

Maintenance quality is more stable and work time can be significantly reduced, compared with manual work.