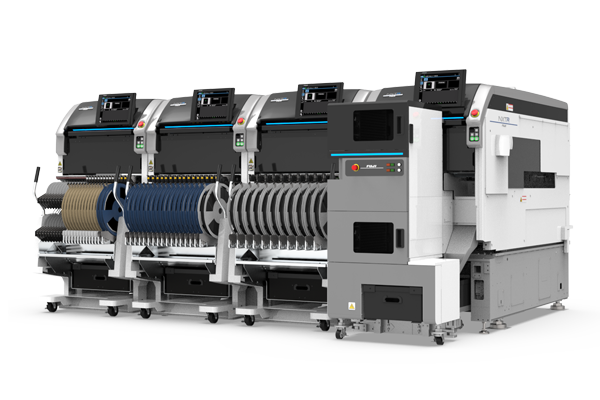

In line with the spread of IoT, which has led to the evolution of household electronics, the control panels for household electronics have become complicated. On the other hand, relatively large parts related to power supply and leaded parts still need to be placed. Fuji mounters support a wide variety of parts, which is one of our advantages.

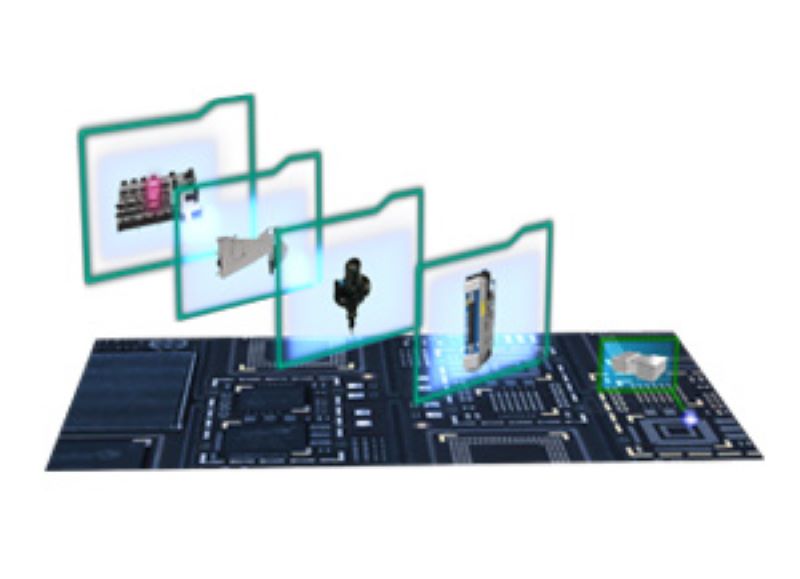

Traceability

By linking the IDs used to manage the equipment that is thoroughly modularized and unitized to the placement data managed by individual references, it is possible to acquire detailed traceability data. This traceability data can be used to identify the related parts, machines, and units used for a particular panel ID or to identify the panels on which a particular part ID was placed.

段取り替えを最小に

To deal with frequent changeovers necessary for the production in this field, Fuji provides a system in which the panel ID or barcode for the product is read and the program is automatically changed to the correct program. It is also possible to reduce the number of changeovers by using production schedule optimization.

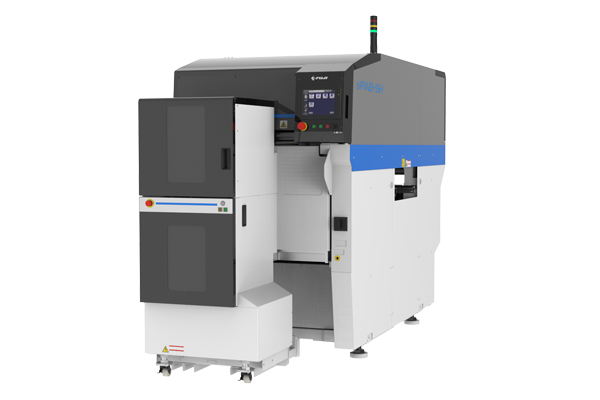

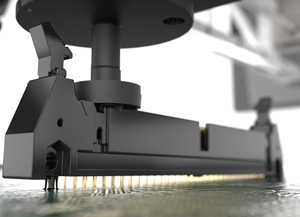

Supports large odd-form parts

The parts to be mounted change as technology advances.

We provide a wide variety of nozzles and chucks capable of handling LEDs and connectors in different sizes and shapes. These support placement from the functional aspect as well.