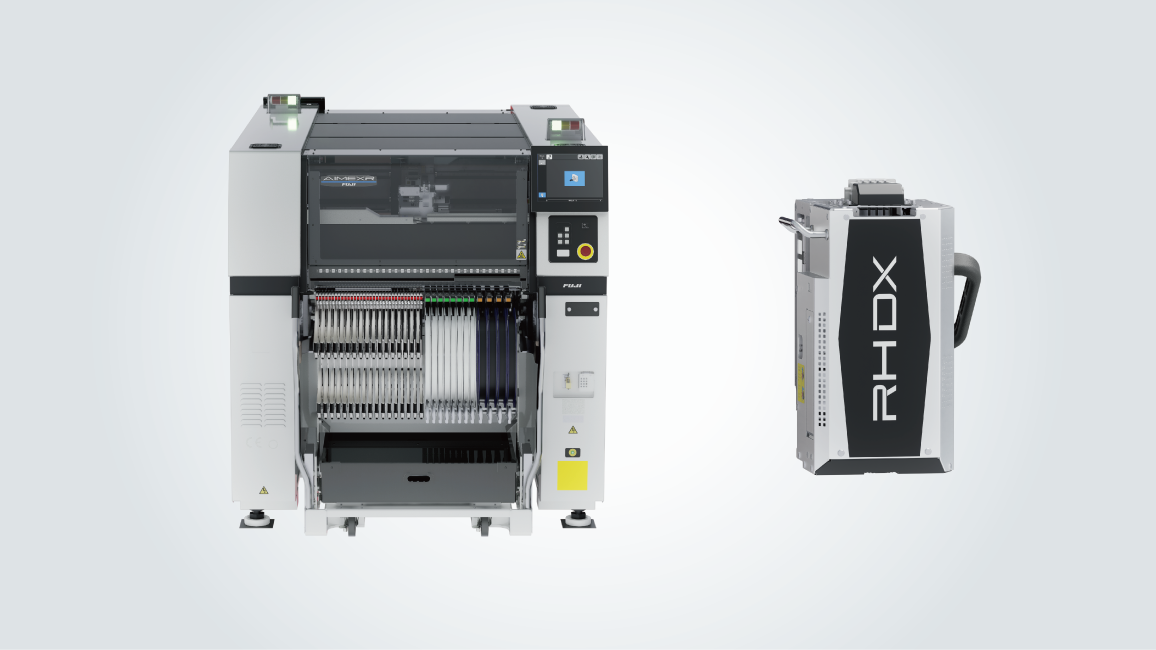

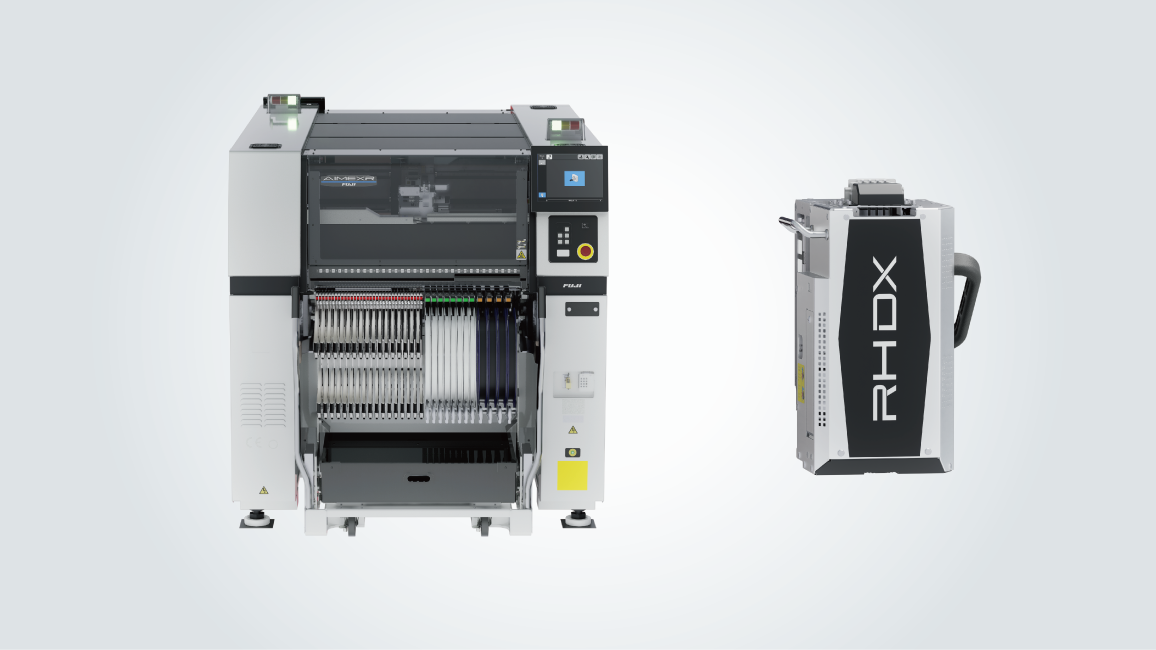

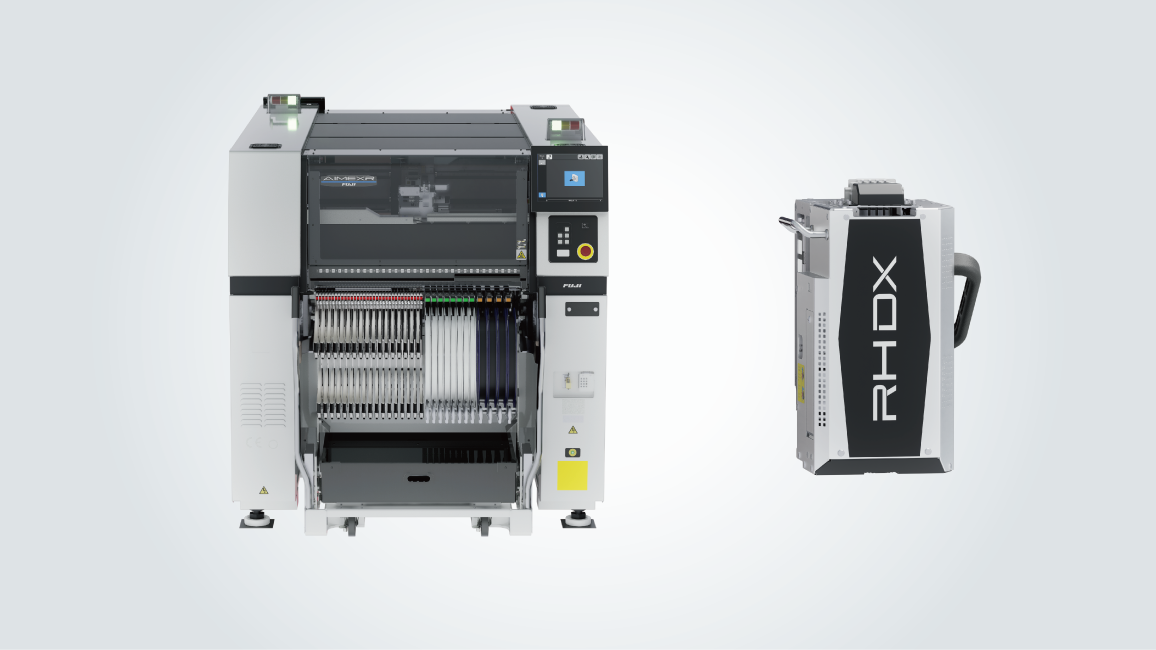

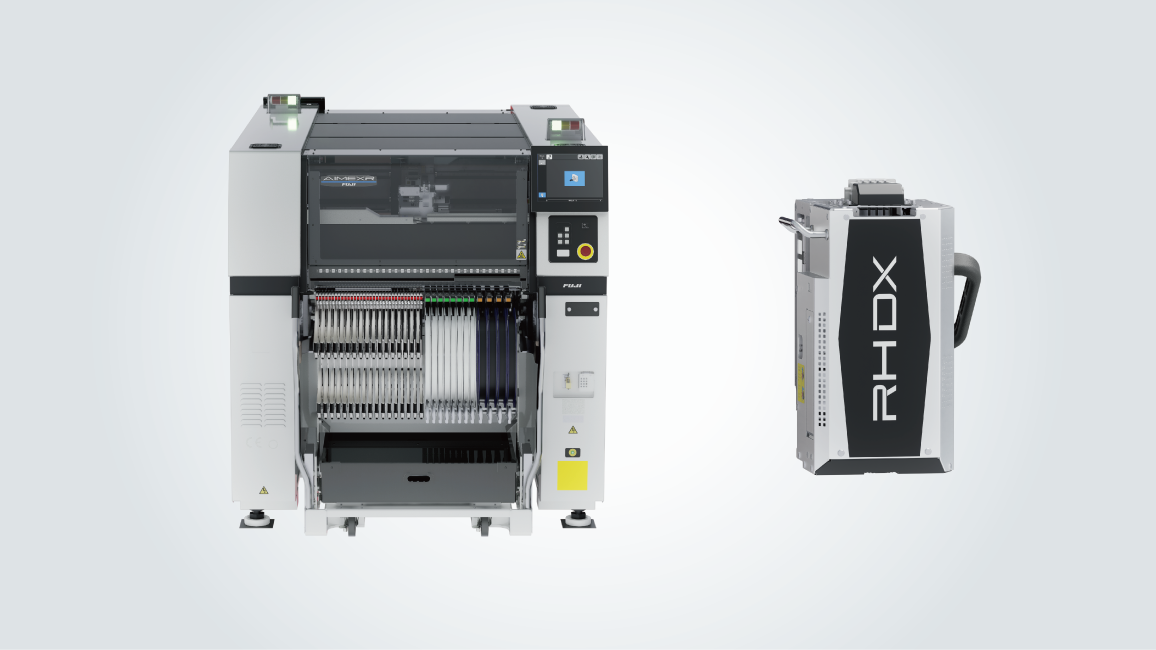

AIMEXR + RHDX heads – Optimal for variable-mix variable-volume production

Electronic panel manufacturing is now facing a wave of diversification.

The increase in the number of placed parts due to the consolidation and enlargement of panels, as well as the expansion of production types and on-demand production, make it essential to respond efficiently to variable-mix variable-volume and high-mix low-volume production.

To meet these challenges, Fuji offers AIMEXR placement machines that support the large capacity part supply units and RHDX heads capable of handling a wide range of parts.

These support various types of manufacturing sites as solutions that combine high productivity and flexibility in variable-mix variable-volume and high-mix low-volume production.

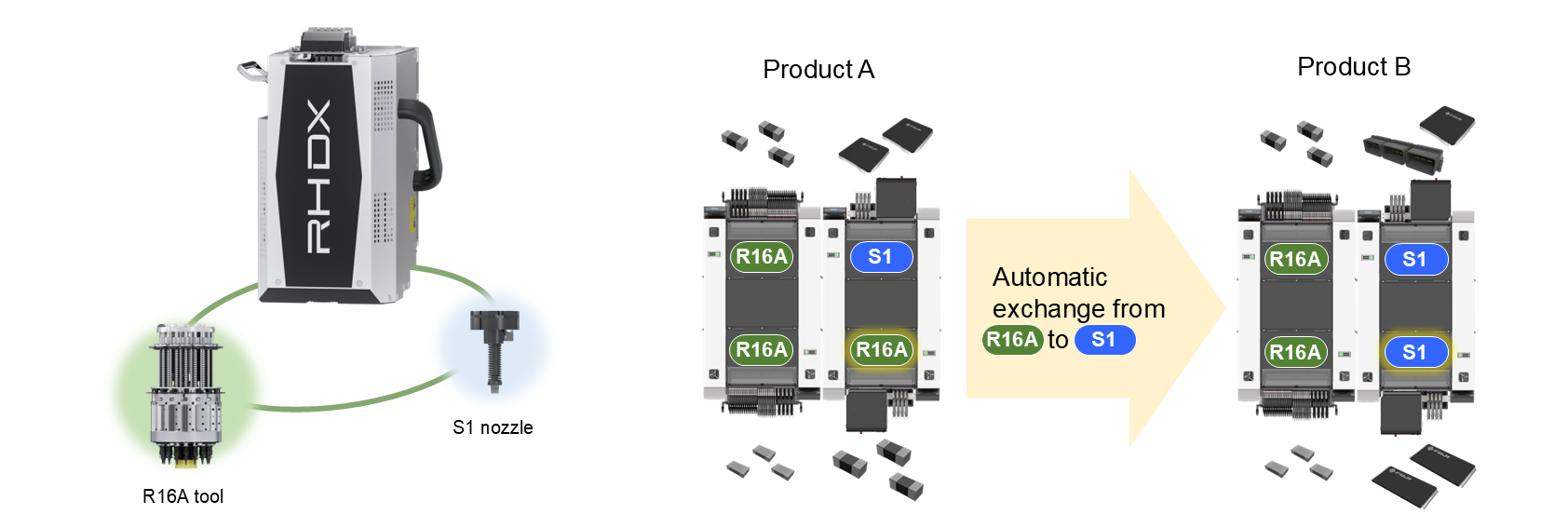

The RHDX head automatically changes nozzles and tools optimized for part size during production.

This allows for efficient production while maintaining line balance even in high-mix low-volume production production.

It can flexibly respond to changes in production types and minimize line downtime during production changeovers.

Automatic tool change according to part size

The RHDX head can handle a wide range of part sizes with a single head, from small 0402 (01005") size parts to large 200 x 150 mm parts.

This minimizes the need for additional equipment, even in production with a mixture of various parts.

It increases the flexibility of production lines and reduces investment costs.

Small parts of 0402 (01005") to large parts of 200 x 150 mm

The RHDX head incorporates the quality assurance features that Fuji has developed for placement heads.

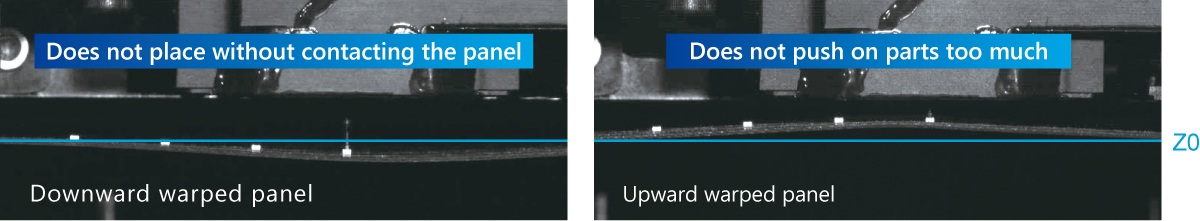

Ensure that parts are not affected by changes in the placement surface height - placement height adjustment:

The placement stroke follows changes in the placement height due to panel warpage and distortions, which allows the machine to control the appropriate push-in amount. This moreover prevents placement deviations and excess stress on parts and panels.

Placement height adjustment

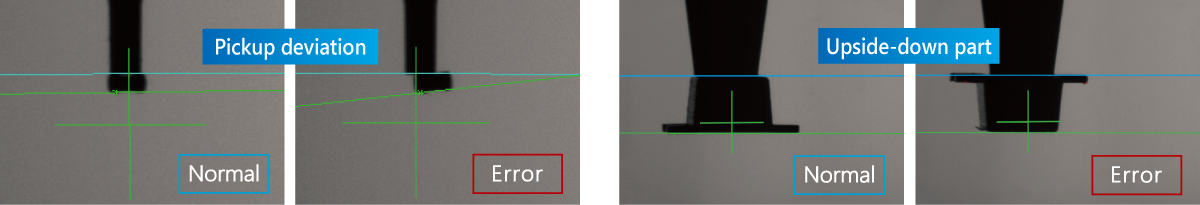

Checks for tombstoned parts, missing parts, and upside-down parts - part check functions:

The installed IPS (Intelligent Parts Sensor) system can cater to a wide range of checks, from part pickup stance to parts remaining on nozzles, as well as upside-down checks for minimold parts. It prevents placement defects attributed to packaging, nozzles, and parts.

- Checks for dropped parts

- Checks the part height

- Checks for parts presence

- Checks for parts remaining on nozzle

- Checks for stuck nozzles

Check parts using IPS

These functions help identify defects before they occur and ensure stable placement quality.

They reduce quality risks and ensure reliable production.