Part placement and glue application by one head | DynaHead (DX)

Fuji’s revolutionary dynamic head, DynaHead (DX), supports flexible production for various production types with only one head.

A new glue tool (compatible with AIMEX-3, AIMEX-3c) has been added to the lineup of freely exchangeable tools. By using tool exchange, part placement and glue application can be done with one head.

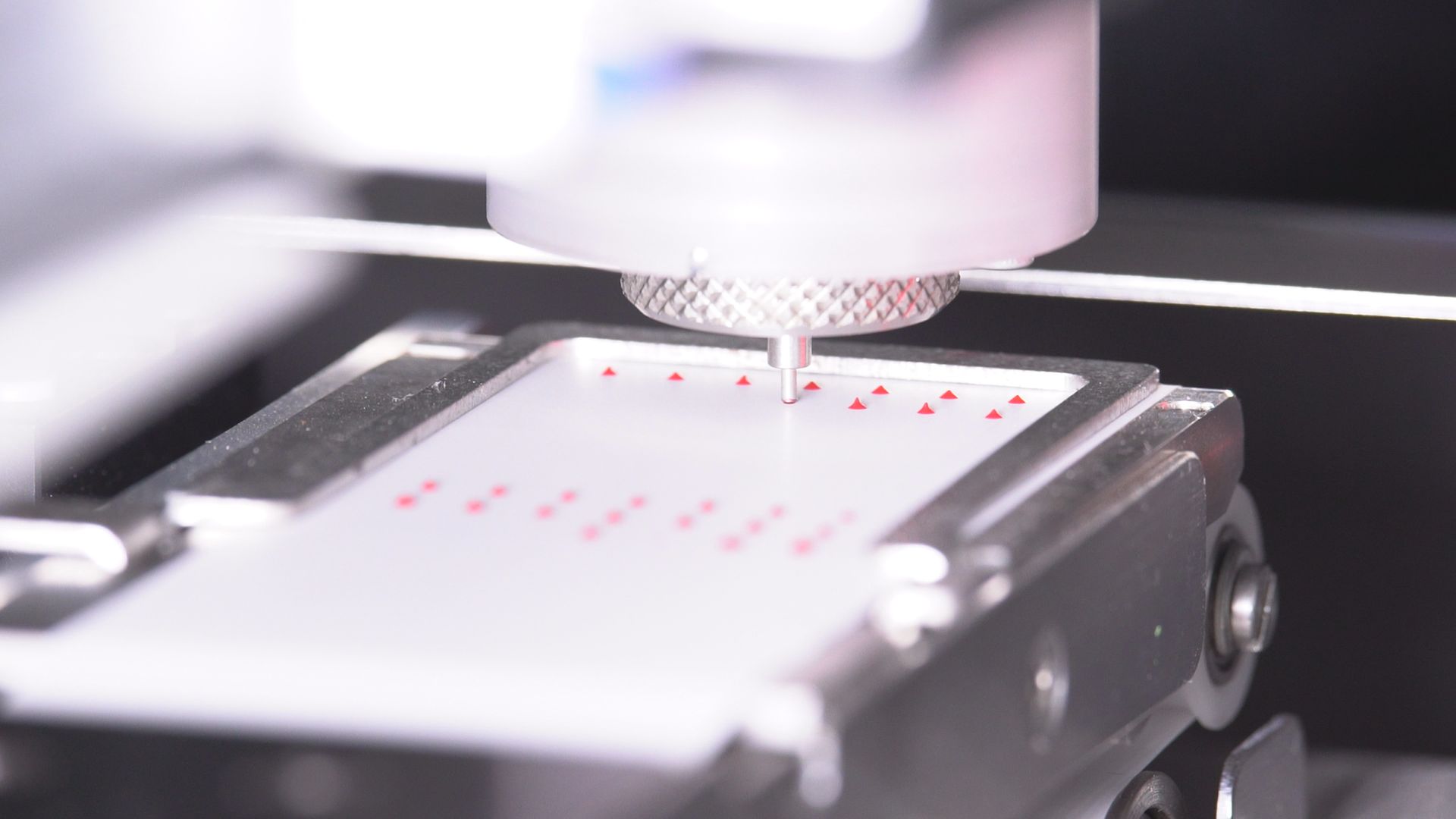

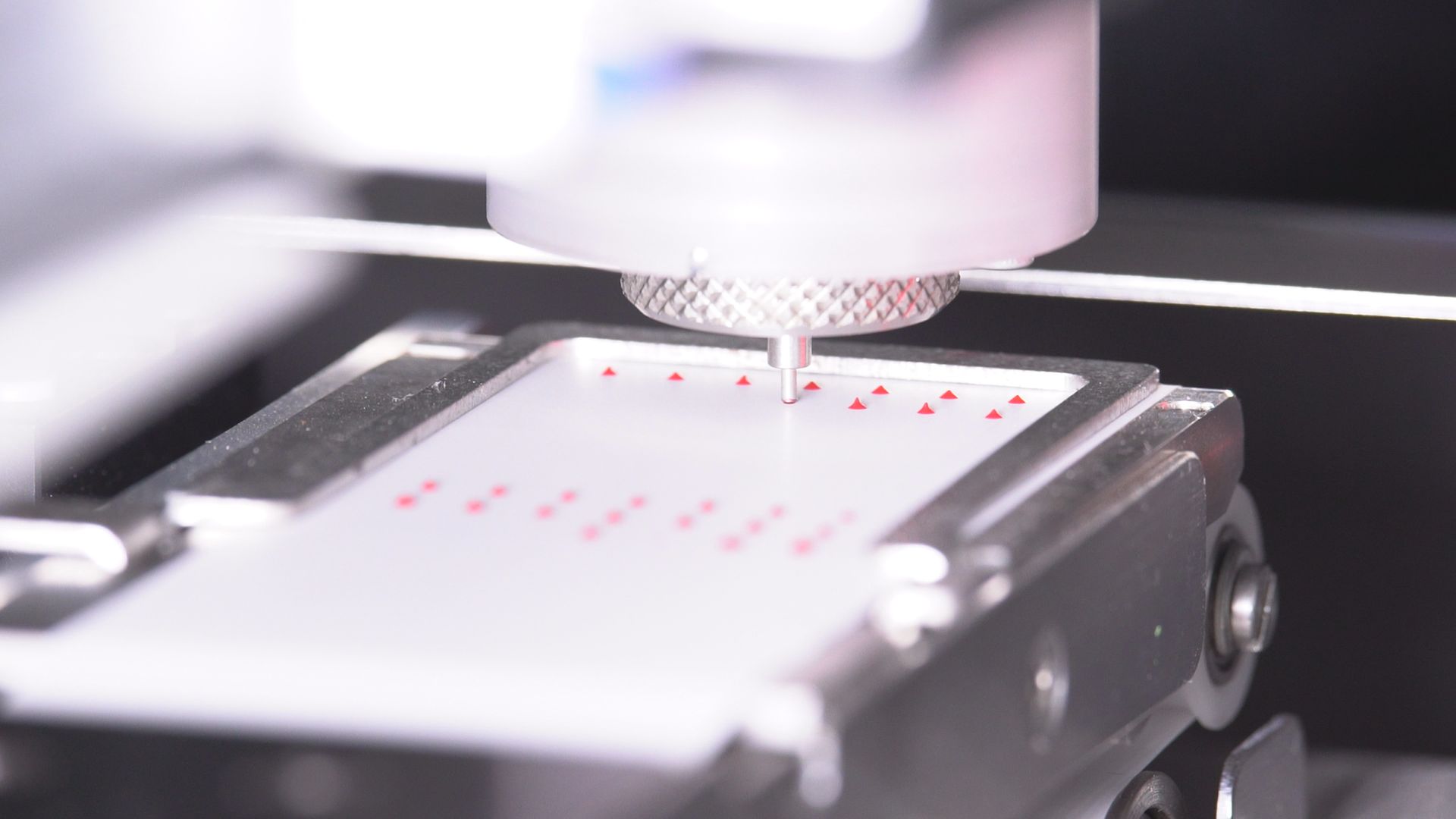

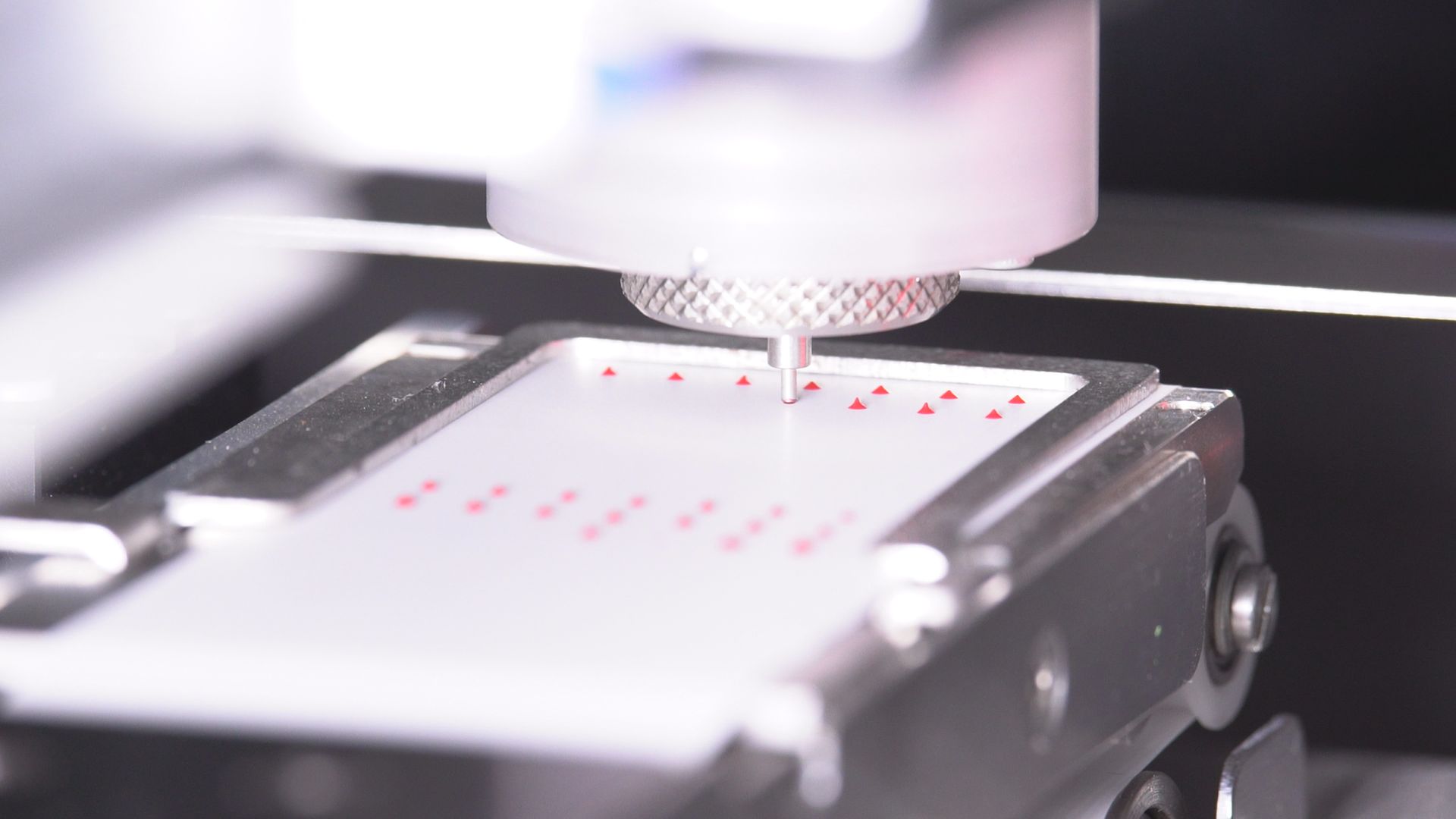

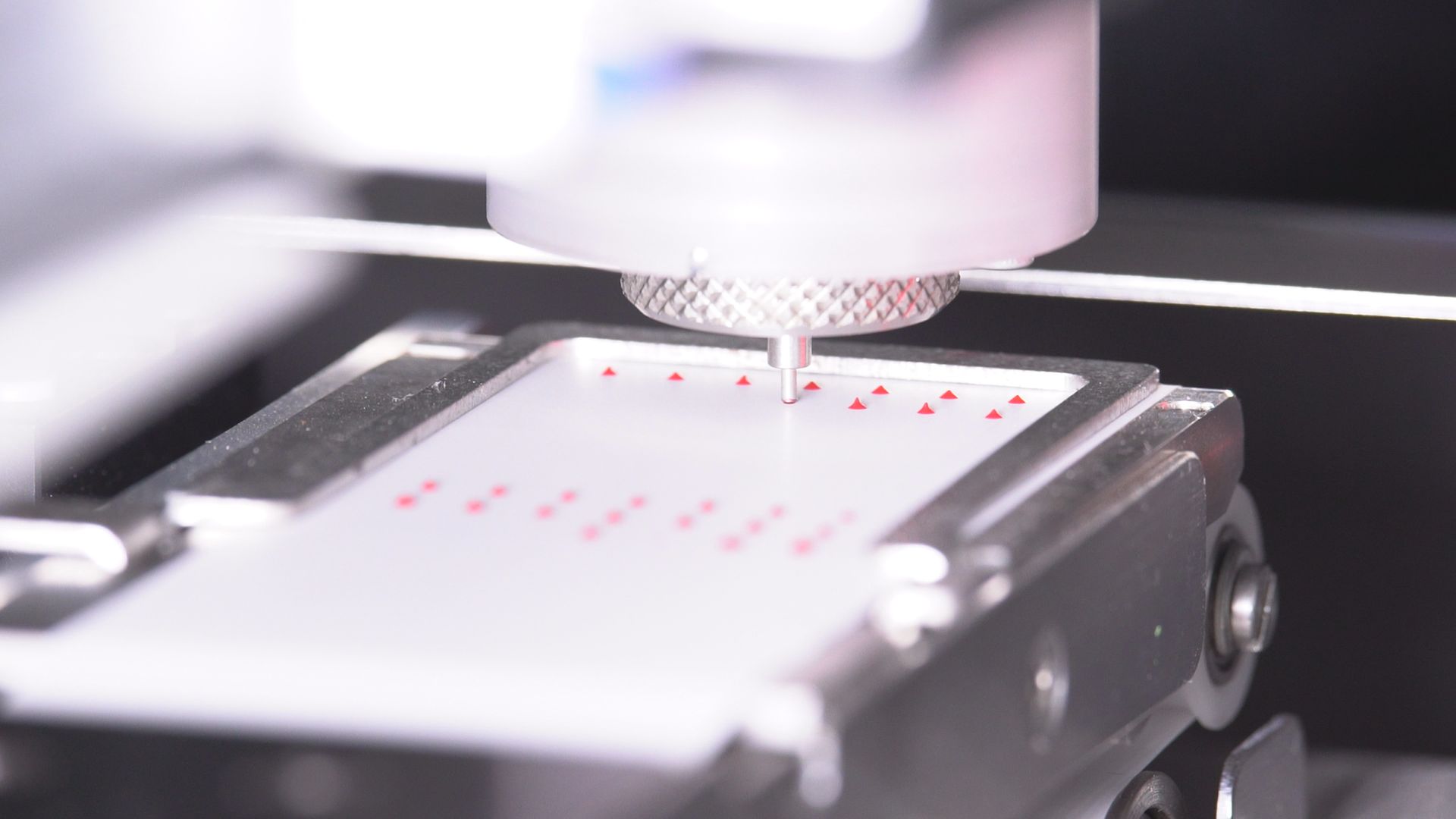

DX head

The DynaHead automatically changes tools based on the part size and shape during production.

A single DynaHead can support a part range from 0402 (01005") up to 102 x 102 mm by exchanging between the R12 tool (12 nozzle operation) for smaller, chip-shaped parts, R4 tool (4 nozzle operation) for medium sized parts, and S1 (single nozzle operation) for larger, odd-form parts.

Introducing a glue tool to the tool lineup also enables the DynaHead to change to a tool for dispensing glue. This glue tool can be used to provisionally secure key parts and prevent defects that occur during reflow in the form of raised parts without needing glue application independent from the placement machine.

This makes it possible to both place parts with a wide range of part sizes and apply glue using the same head, which also means that a single module can become all-in-one glue and placement station.

Each one of Fuji's AIMEX III and AIMEX IIIc machines is a platform geared toward high-mix production, with two-side operation that allows for a maximum of 130 available feeder slots. Because of this, there are still plenty of slots for high-mix production in addition to those occupied by the Glue Check Unit 2 (seven slots) and Glue Tool Station (six slots) that are required to have both glue application and part placement in one machine.