Preventing defective pickup and placement

Are you overlooking problems in placement processes?

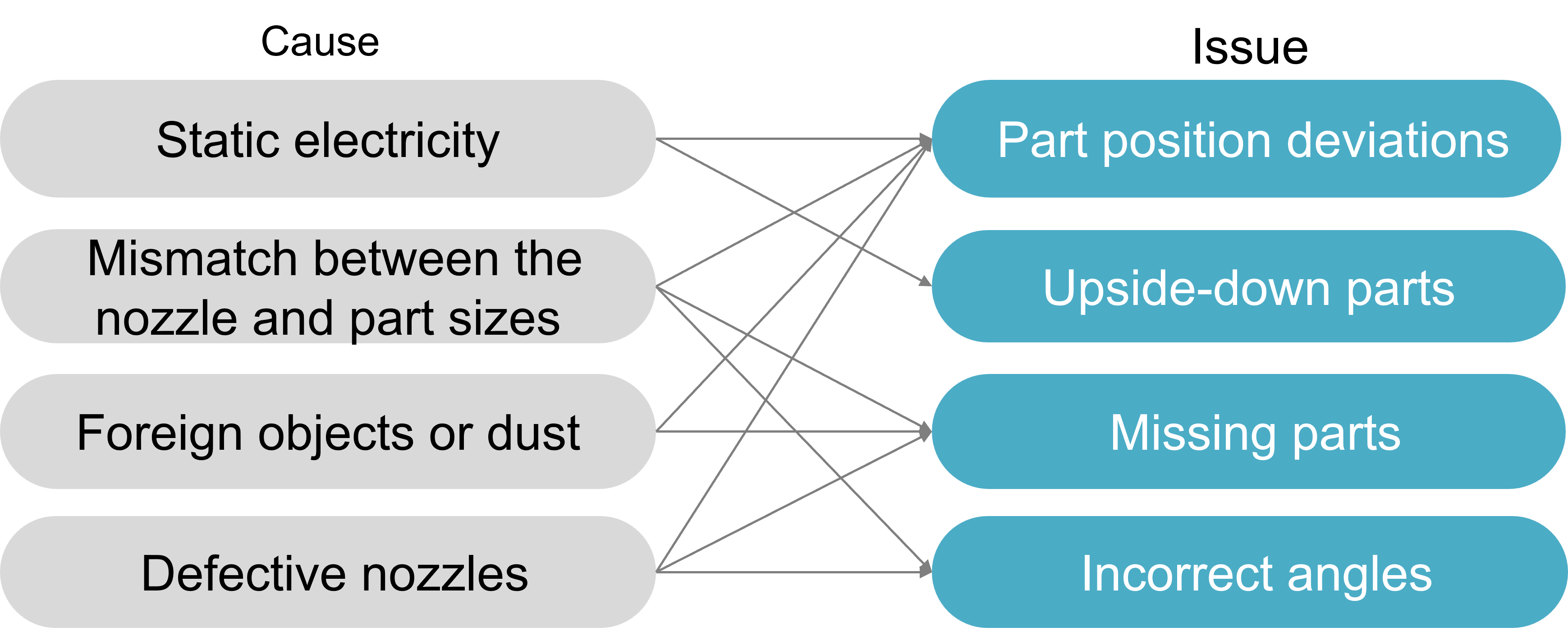

Have you identified the cause of repeated pickup and placement defects?

Even a slight defect at the nozzle tip can directly lead to serious problems on the panel.

This document focuses on problems frequently occurred at production sites and introduces hints for solving issues through our solutions.

Be sure to check it out.