Resupplying parts without splicing

Operators on SMT lines perform a wide variety of tasks.

Of these, supplying parts to the placement machines is the most demanding, accounting for more than 30% of the total workload.

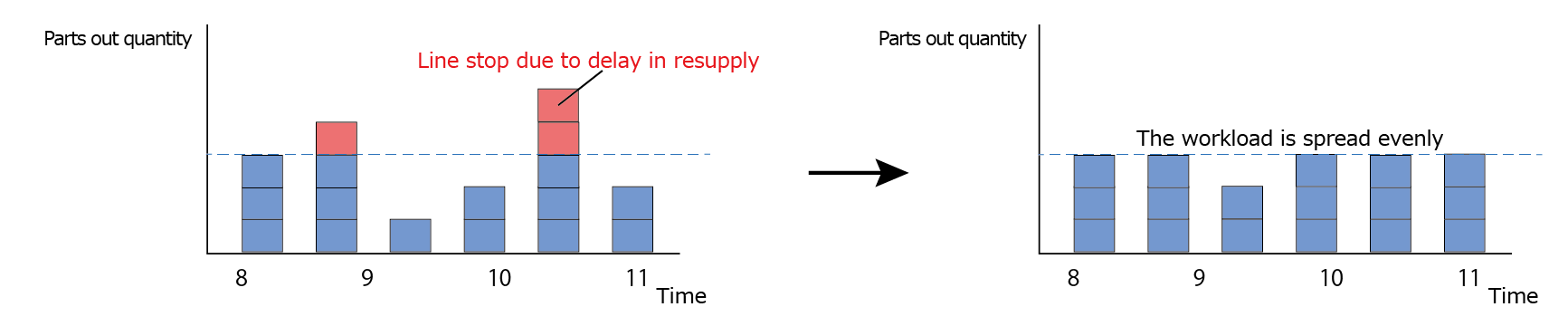

The timing for performing this work often overlaps with that for other tasks and such concentrated workloads can cause supply delays and human errors, resulting in production stops.

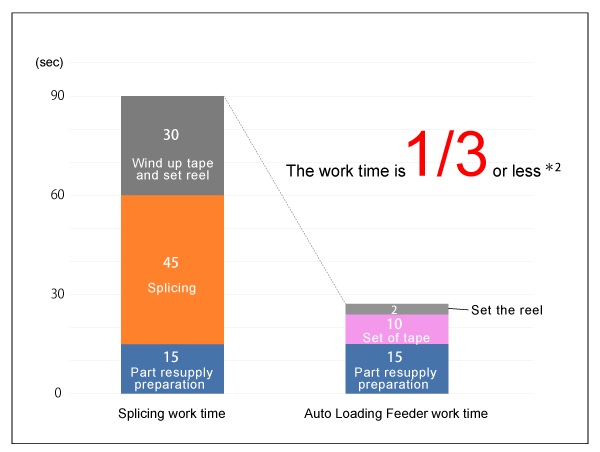

Auto Loading Feeders have a next generation method for parts replenishment that solves the problems associated with part resupply and helps improve OEE.