The ideal solution for high-speed placement of chip parts and LEDs – NXTR S model high-speed placement package

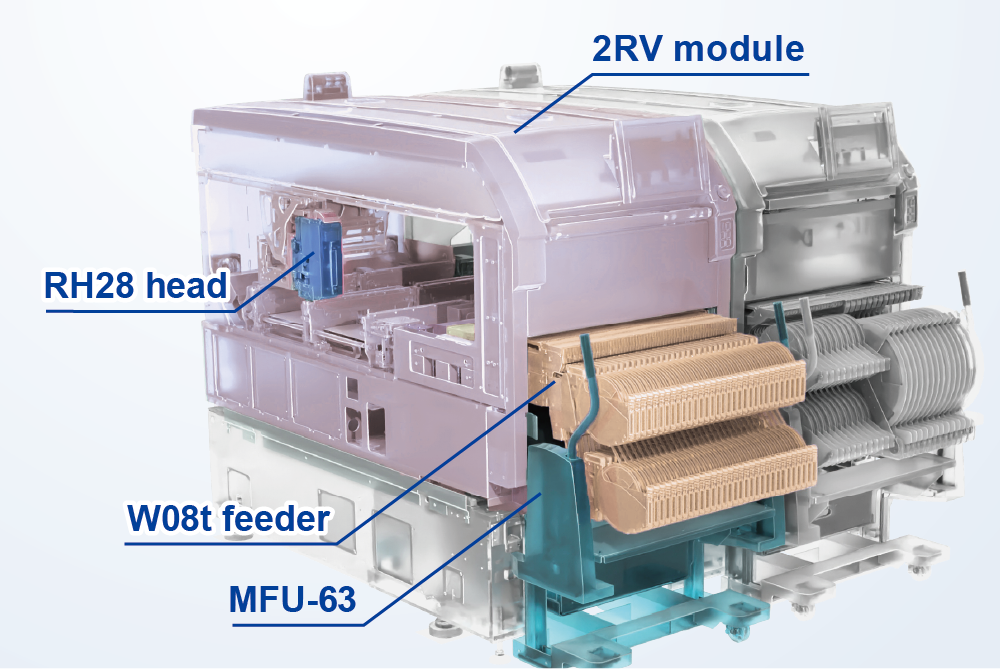

By combining the newly developed 2RV module with RH28 heads, W08t feeders, and MFU-63 feeder carts, the NXTR delivers a top-in-class throughput of 120,000 cph. This is a 39% improvement when compared with the NXT III. It is highly effective for part placement on panels such as for mobile devices and notebook computers that have many small parts and LEDs.

2RV modules can be loaded on the same base as 2R modules or 1R modules, enabling production line configurations that can cater to a wide range of panel types.

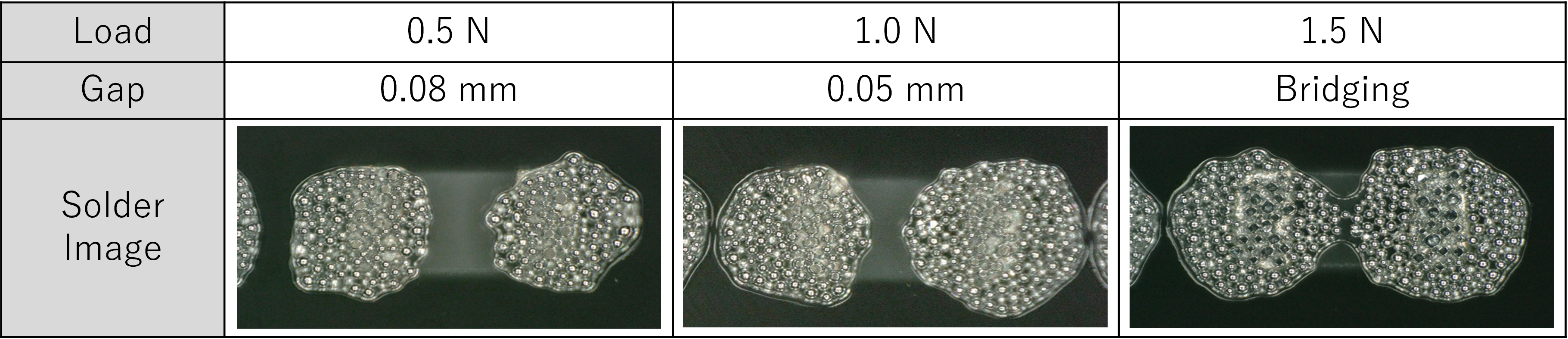

Our low-impact nozzles that have been developed in-house enable ultra low impact placement at 0.5 N. (See note 1)

Very small chip parts, including 0201 (008004") parts are continuing to be used in the small panels for mobile devices, with circuits being designed to have finer pitches between parts. This prevents bridging caused by flattened solder and part breakage, which can easily occur in this type of panel production.

Note 1: According to test results attained at Fuji

Solder flattened during placement of a 0402C (01005"C) part

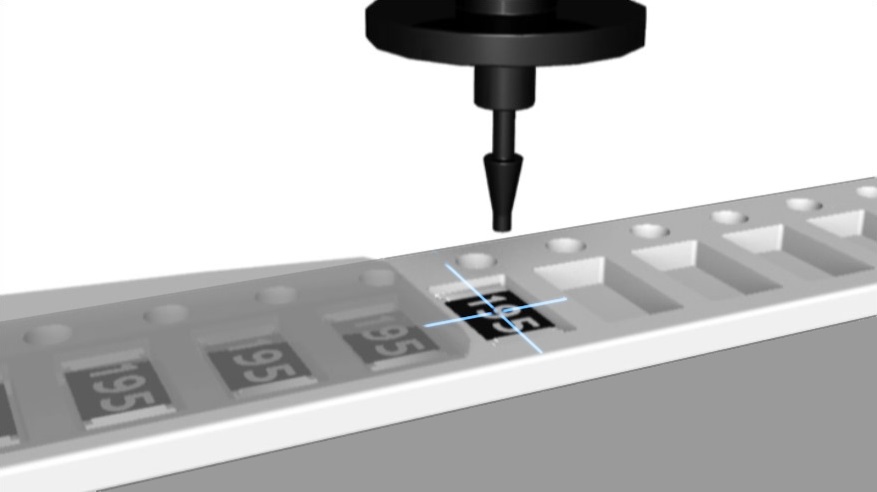

In addition to the function for general placement position correction using vision processing, the NXTR S model high-speed placement package also has an improved pickup position correction function that takes into account discrepancies between individual feeders. By correcting the pickup position in both the X and Y directions, it is possible to always pick up parts accurately at the target point, avoiding interference with adjacent parts due to the tip of the nozzle protruding beyond the picked part, which is a concern in fine pitch placement, to achieve high quality production.

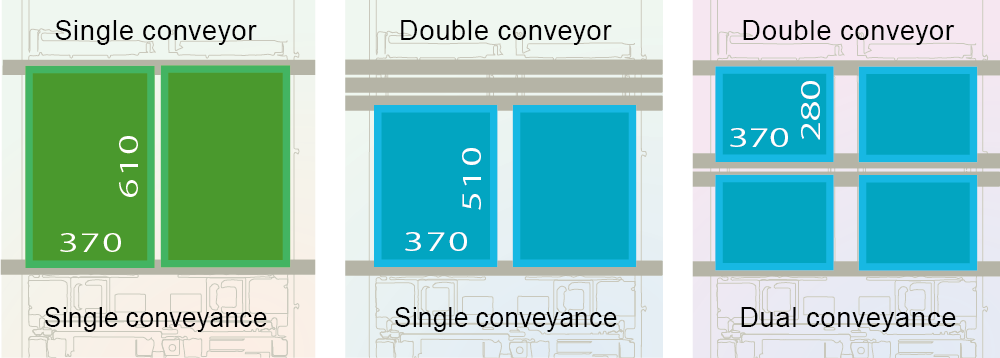

Up to 52 types of parts (8 mm tape equivalent) can be loaded (30% increase compared with the NXT III).

Even panels that require many types of parts, such as those for smartphones, can be produced with fewer machines due to the increased feeder capacity. This machine also demonstrates a wide range of improvements related to throughput, improving the CPP (15 to 20% increase compared with the NXT III). (See note 2)

Note 2: Improvements in CPP vary depending on the panel type

2RV modules can produce four panels at a time for panels up to 370 x 280 mm (placement area of 330 x 274 mm) when using double conveyor dual conveyance. This contributes to improved productivity when producing panels for notebook computers and automotive use.

Please contact us if you have any further questions about the NXTR S model high-speed placement package or any other solutions.