Starting small in automating insertion processes using SCARA robots Panel Assembly Robot Cell – SmartWing BA

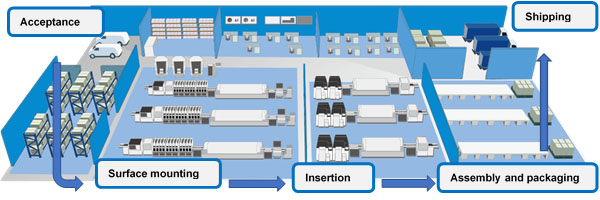

Electronic circuit boards used in automobiles and home appliances go through the following processes; "parts acceptance", "surface mounting", "insertion", and "assembly and packaging", before they are ready for shipment. (Refer to image 1)

Image 1

Out of these processes, the surface mounting process has shown considerable progress in automation due to the evolution of pick and place machines (chip mounters) and peripheral equipment. However, the insertion process for handling odd-shaped leaded parts such as connectors and aluminum electrolytic capacitors is still performed manually due to such parts being supplied using loose-supply packaging and the relatively small quantity of parts to be inserted. Thus, there are still issues to address regarding quality and productivity.

To solve the quality and productivity issues that many of our customers face in the insertion process, we have packaged SCARA robots and vision systems into a cost-effective and easy-to-use Robot Cell, the SmartWing BA.

The main features of SmartWing BA are as follows.

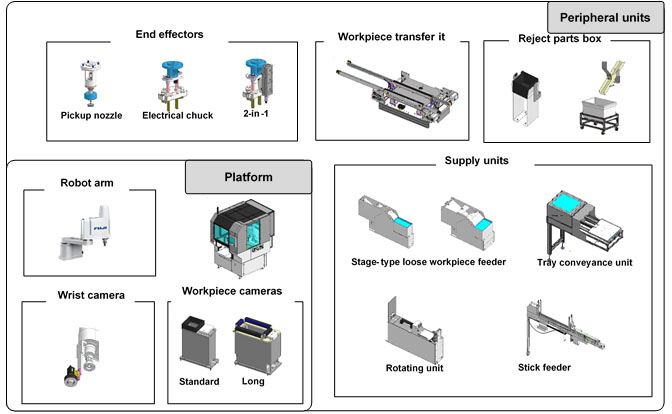

The SmartWing BA platform consists of a SCARA robot with a payload of 6 kg and a reach of 700 mm, and two types of cameras for part recognition; a wrist camera attached to the tip of the robot arm and a workpiece camera attached to the base. (Image 2)

The wrist camera recognizes the position of the panel when loaded and the pick-up position of the supplied parts. The workpiece camera recognizes the part shape, the position and pitch of the insertion pins, and the direction of the part by performing image recognition of the underside of the part. The automation of insertion work that requires accuracy is realized by utilizing the image recognition information obtained from these two cameras and correction technology in cooperation with the robot arm.

A number of peripheral units are prepared as standard, as shown in image 2. System setup for the machine is performed simply by selecting each unit according to the parts to be inserted.

Image 2

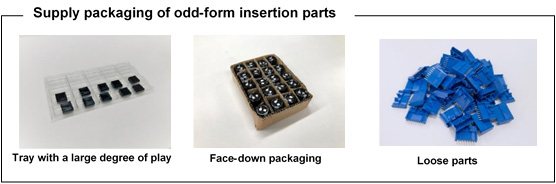

Odd-form insertion parts are often supplied loose or in trays that have a lot of play.

To automate insertion of these parts, it is usually necessary to transfer them to special trays, which hinders improvement of the automation rate.

SmartWing BA recognizes the entire parts supply area by using its wrist camera. This enables accurate pickup at the center of a part even when the part is supplied in a tray with a large degree of play in the tray cavities. For parts supplied in bulk, multiple workpieces on a supply stage of a stage-type loose workpiece feeder can be recognized using image recognition, and only those workpieces in a position that is possible to pick up from are picked up.

These functions enable direct supply and automatic insertion of workpieces without changing the packaging, even if the workpieces are supplied loose. (Image 3)

Image 3

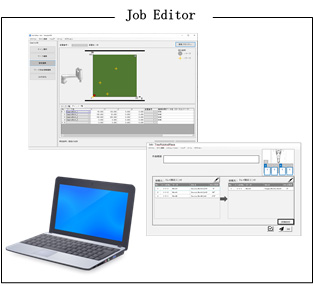

Job Editor, a production program creation tool, is used to create production programs.

Job Editor allows the user to create operation programs simply by entering numerical values for "workpiece information" (information on workpiece shape), "panel information" (information on insertion coordinates), and "workpiece supply information" (information on workpiece pickup position), or by selecting them from a drop-down menu on a computer with Job Editor installed. Teaching work like that used for a typical SCARA robot is not required, and operation programs can be created and edited simply by inputting numerical values. (Image 4)

Shape data is created using Shape Editor that comes with the machine. First, follow the GUI of Shape Editor to enter the setting values. Next, the workpiece is imaged on the machine, and from the taken image of the actual part, the color of the workpiece and background, the outline outline, and the shape of the tips of the insertion pins are automatically extracted. Finally, enclose the workpiece image with a rectangle to finish creating the shape data (Image 5).

By using both Job Editor and Shape Editor, additions and changes can be made without any specialized knowledge of teaching or programming.

Image 4

Image 5

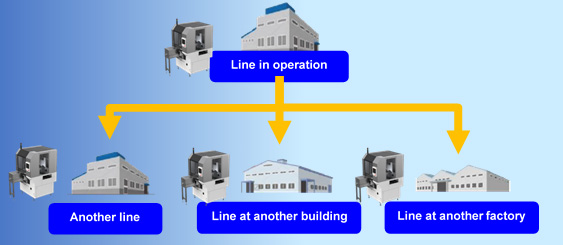

SmartWing BA can be used as a stand-alone machine, while having no differences between each robot by taking advantage of the "cell" configuration style. This means that the same program can be used to expand production not only to new equipment, but also to new installations of copied lines, making it possible to start up production in a short amount of time. (Image 6)

Image 6

With these features, SmartWing BA can be used not only for the automation of insertion processes, but also in other various locations and applications in the production factory, such as pre-preparation processes to distribute the required quantities of parts and the automation of sub-assembly processes before the main assembly.

The above is an introduction to starting small in automating insertion processes using Panel Assembly Robot Cell - SmartWing BA

SmartWing BA can be seen in action in our showroom. For customers who are unable to visit the showroom, we also offer online demonstrations.

For more information about our products or to arrange a tour of our showroom, please feel free to contact us.