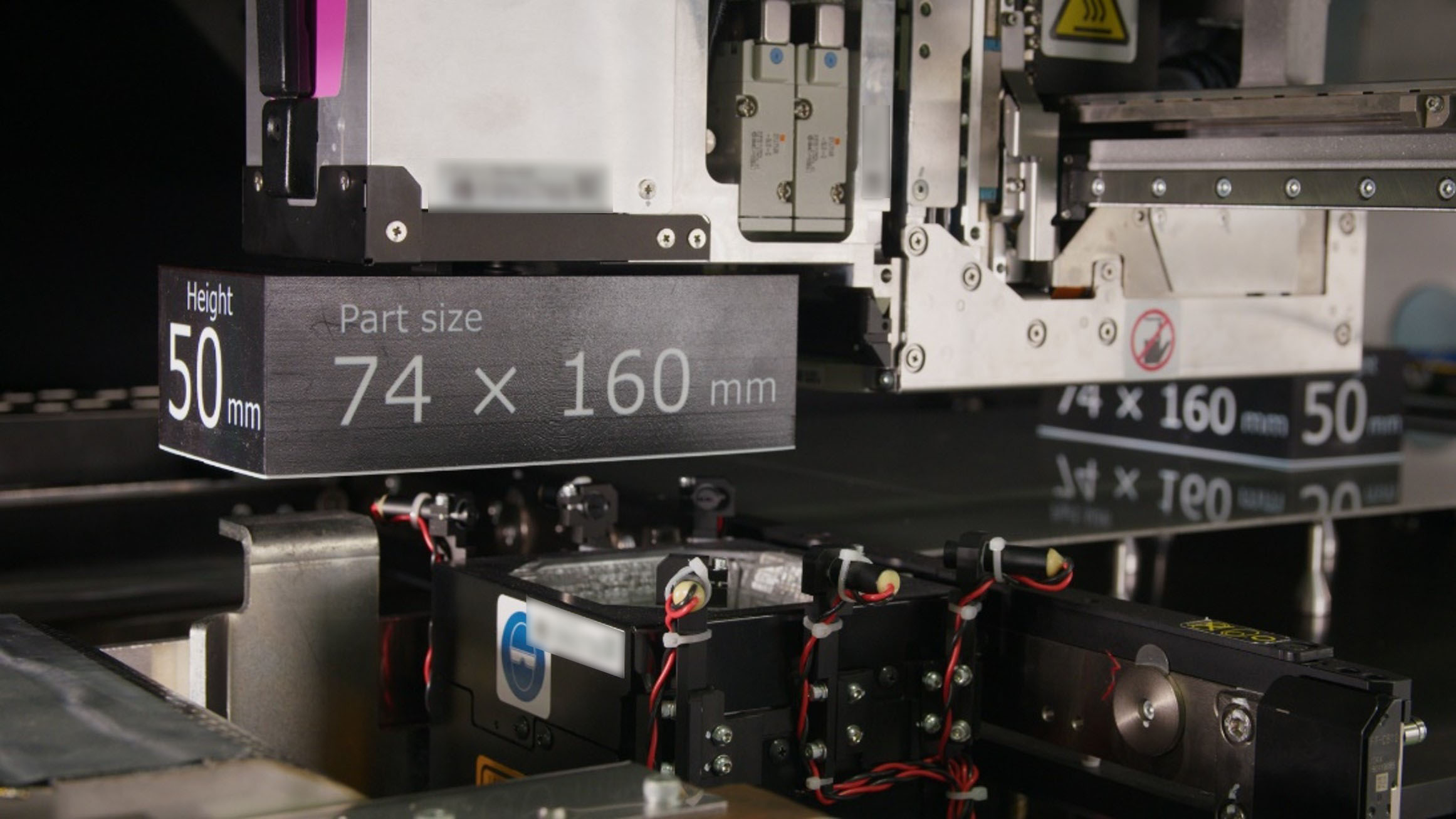

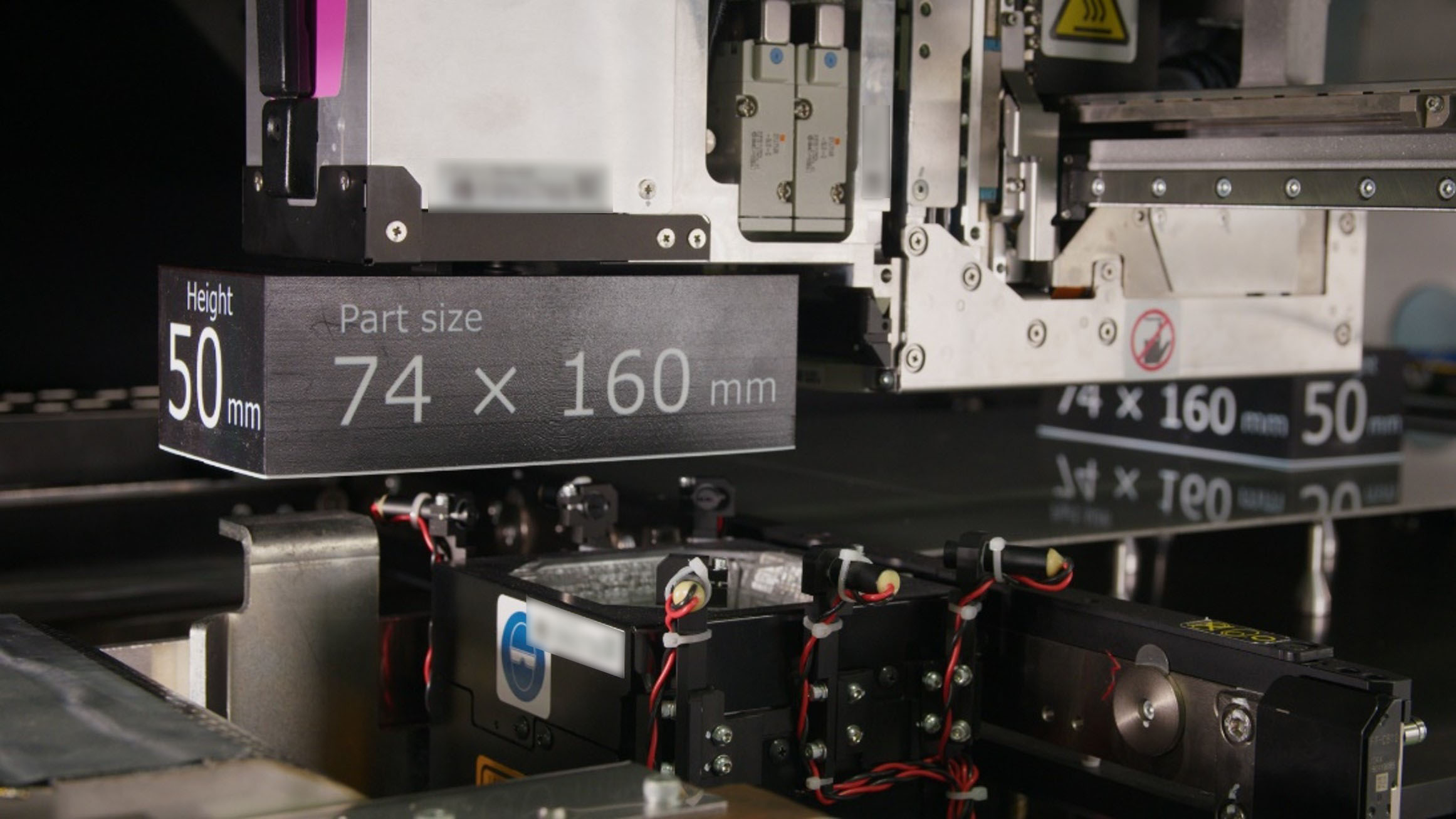

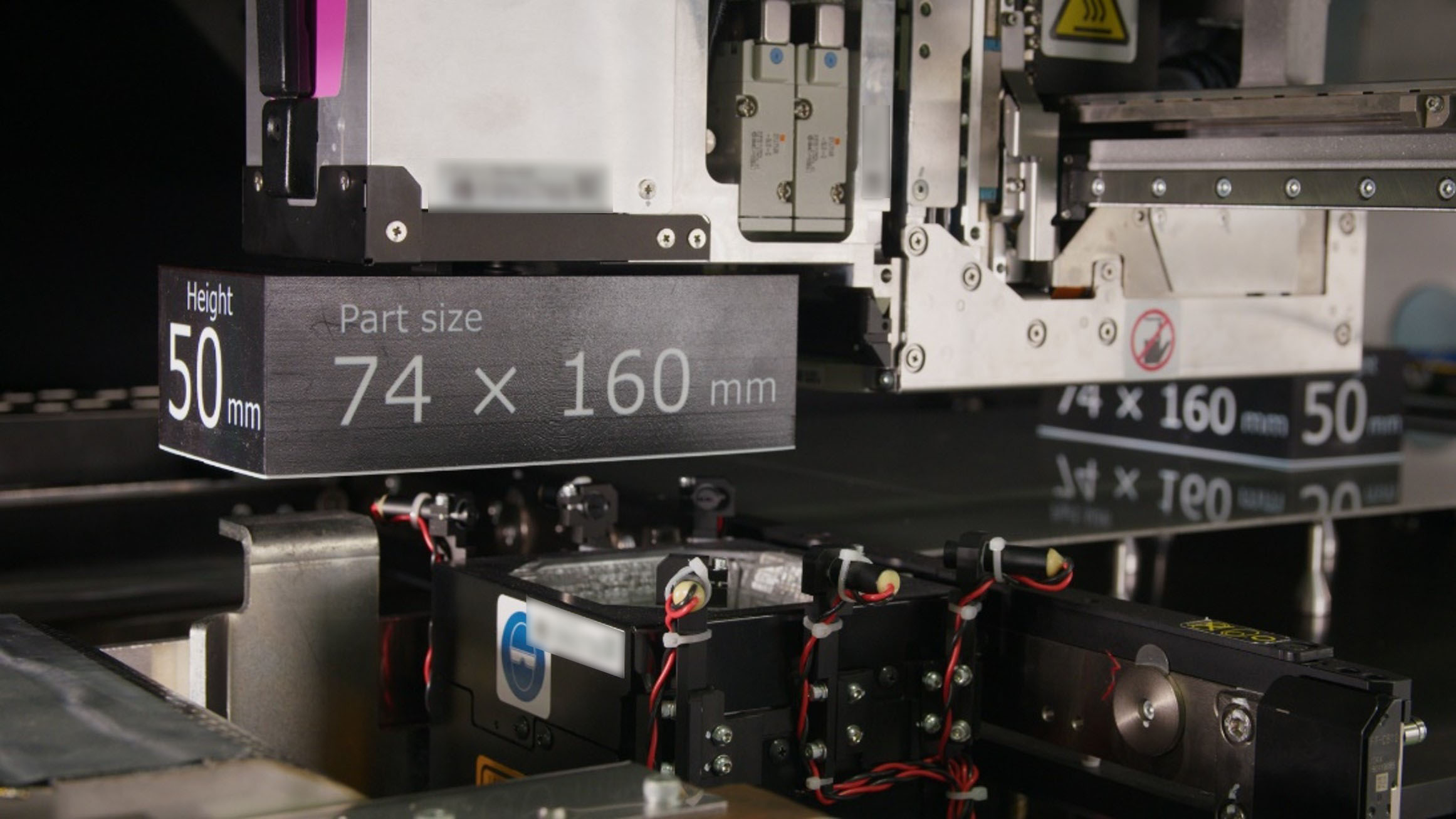

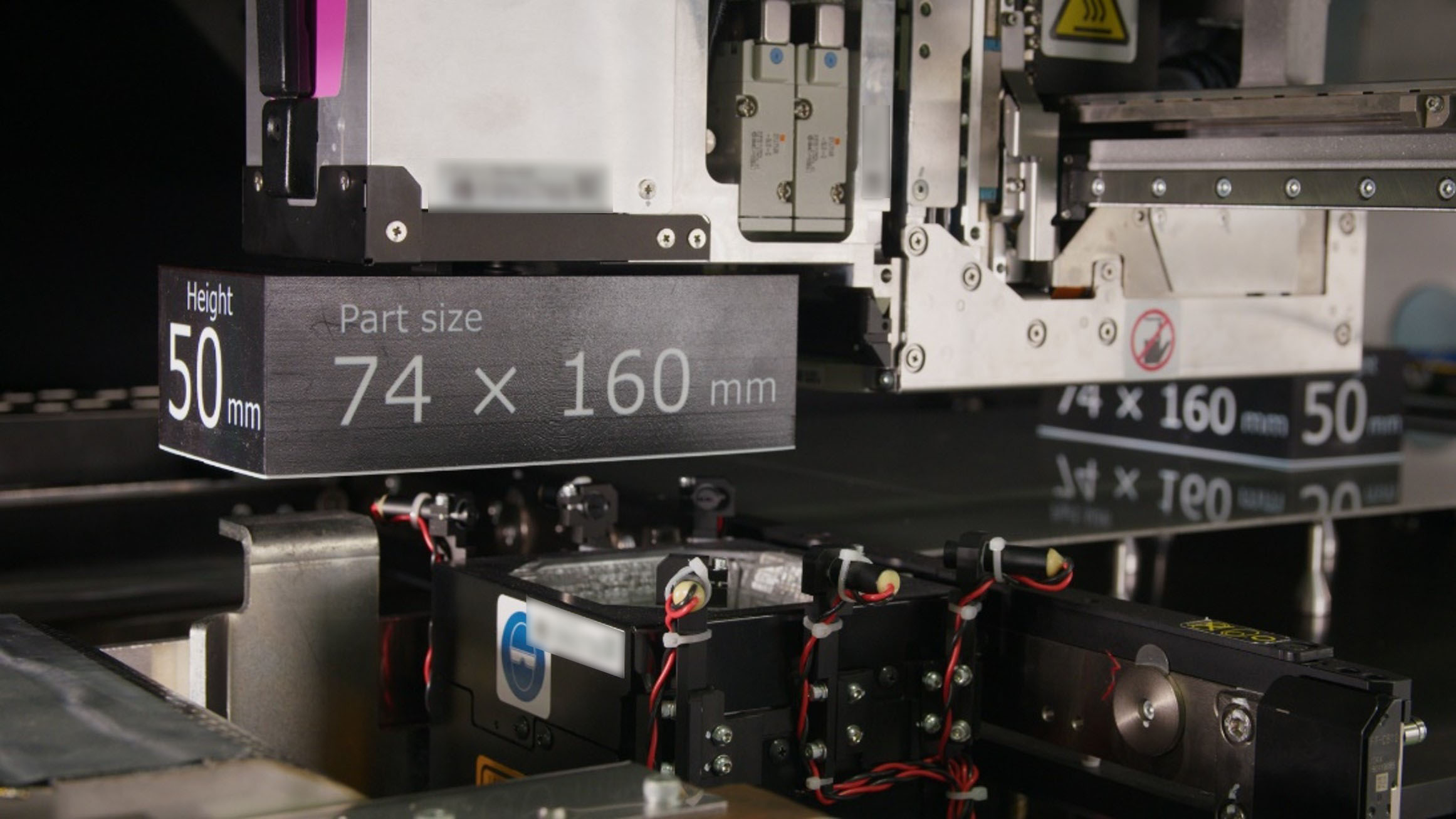

Support parts up to 50 mm tall – NXTR 1RT modules change production sites making zero manual labor possible

In production environments, there are cases in which the placement of tall parts and large parts pose significant challenges. A notable example is the increasing use of large connectors for control boards for industrial equipment and automobiles, which are becoming increasingly electrified. Many of these parts are too large to be handled by standard placement machines, so the placement process inevitably remains a manual one.

On one hand, manual work has strengths such as flexible support and fine-tuning with delicate senses. In fact, complex assembly and fine positioning have been supported by manual work at many sites.

However, processes that rely on human skills also face the following challenges.

- Quality risks due to worker variance

- Manual labor increases time and costs

- Increased onsite workloads due to complex process management

The challenge lies between the limits of machines and human skills.

This is a major factor that has prevented the automation of placing tall and large parts.

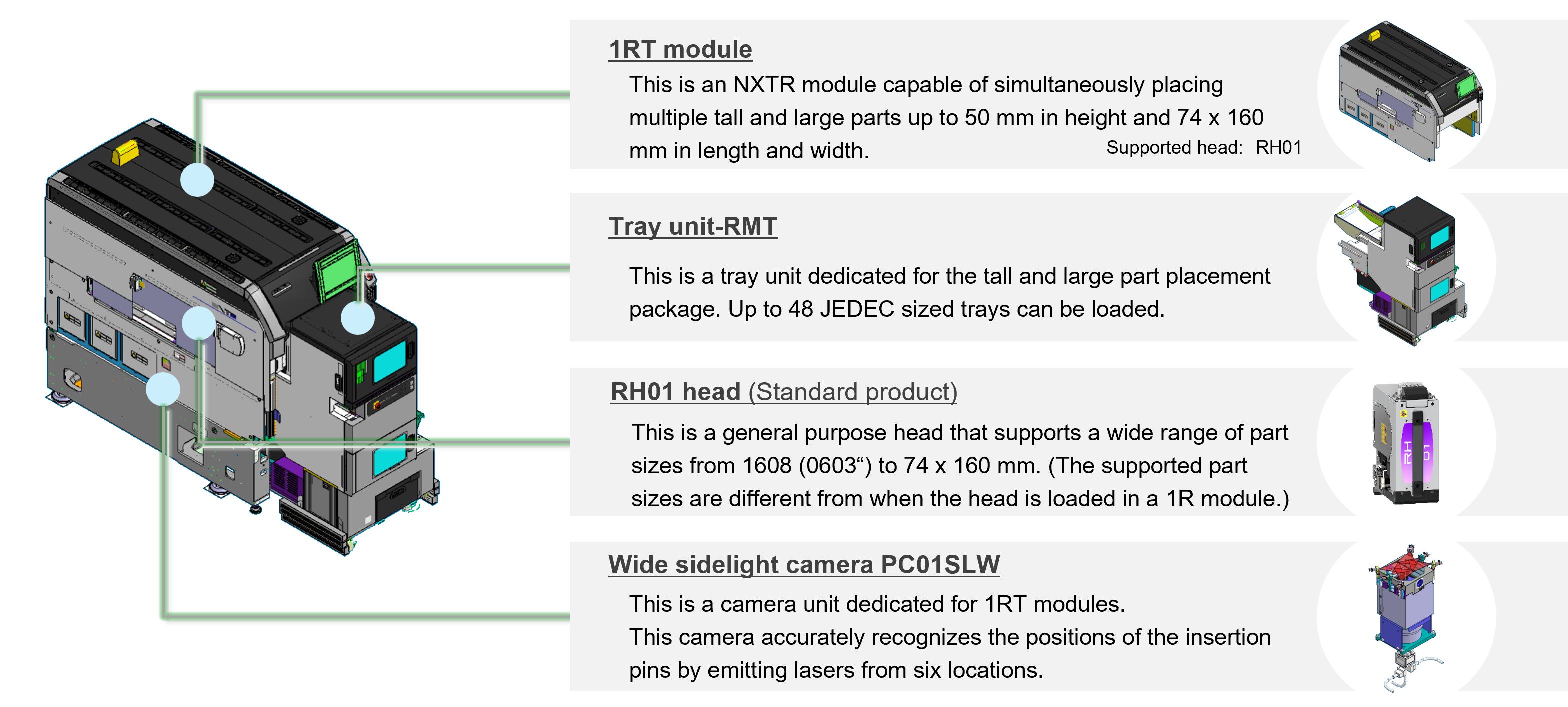

The NXTR 1RT module was developed to solve this problem.

This module, in combination with a dedicated tray unit and vision processing camera, enables automatic placement of parts up to 50 mm in height.

By automating the placement of large parts, which is usually done manually, it is possible to realize flexible production that exceeds conventional limits.

1. Efficiency - Has both speed and flexibility

Lead times are reduced by automating work and even high-mix low-volume production can be flexibly supported. Speedy production can be performed.

2. Stable quality - Breaking away from depending on people

This eliminates variability from manual work and maintains stable quality even after long hours of production. It is possible to reduce risks to quality to a minimum.

3. Simplifies management - Reduced workloads onsite

Processes are streamlined and inventory and progress are easier to manage. This makes it possible to reduce waste and manage production smarter.

Support more efficient and sustainable manufacturing by flexibly responding to changing production needs

By automating processes that previously had to reply on manual work with NXTR 1RT modules, it is possible to both improve productivity and stabilize quality. The adoption of this module, which does not merely save labor, but reduces workloads on the factory floor while realizing stable operation, is progressing at production lines around the world.

This has provided an overview of the NXTR 1RT module.

For more specific functions and specifications, download detailed materials below.