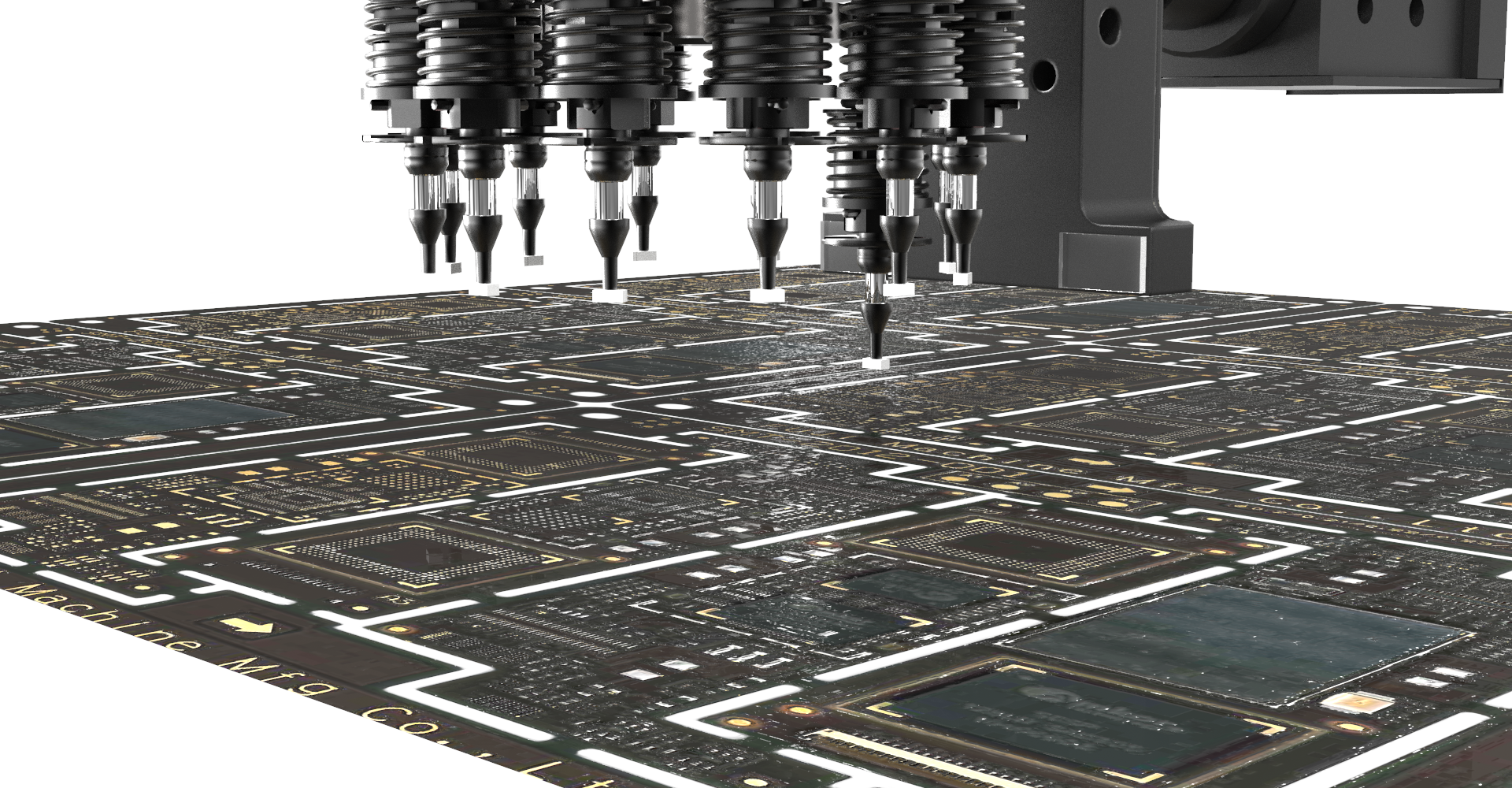

Placing parts with high accuracy

In addition to the advancement of smaller electronic parts and more complex electronic circuit designs, growing needs for finer pitch placement is making filletless soldering more popular. A small amount of solder is applied when performing fine pitch placement using very small sized chip parts, which makes it difficult to expect such parts to be applicable for self-alignment effects. Instead, producing accurate part placement to put parts in a definitive place is required.

The following introduces positioning techniques for achieving highly accurate placement.

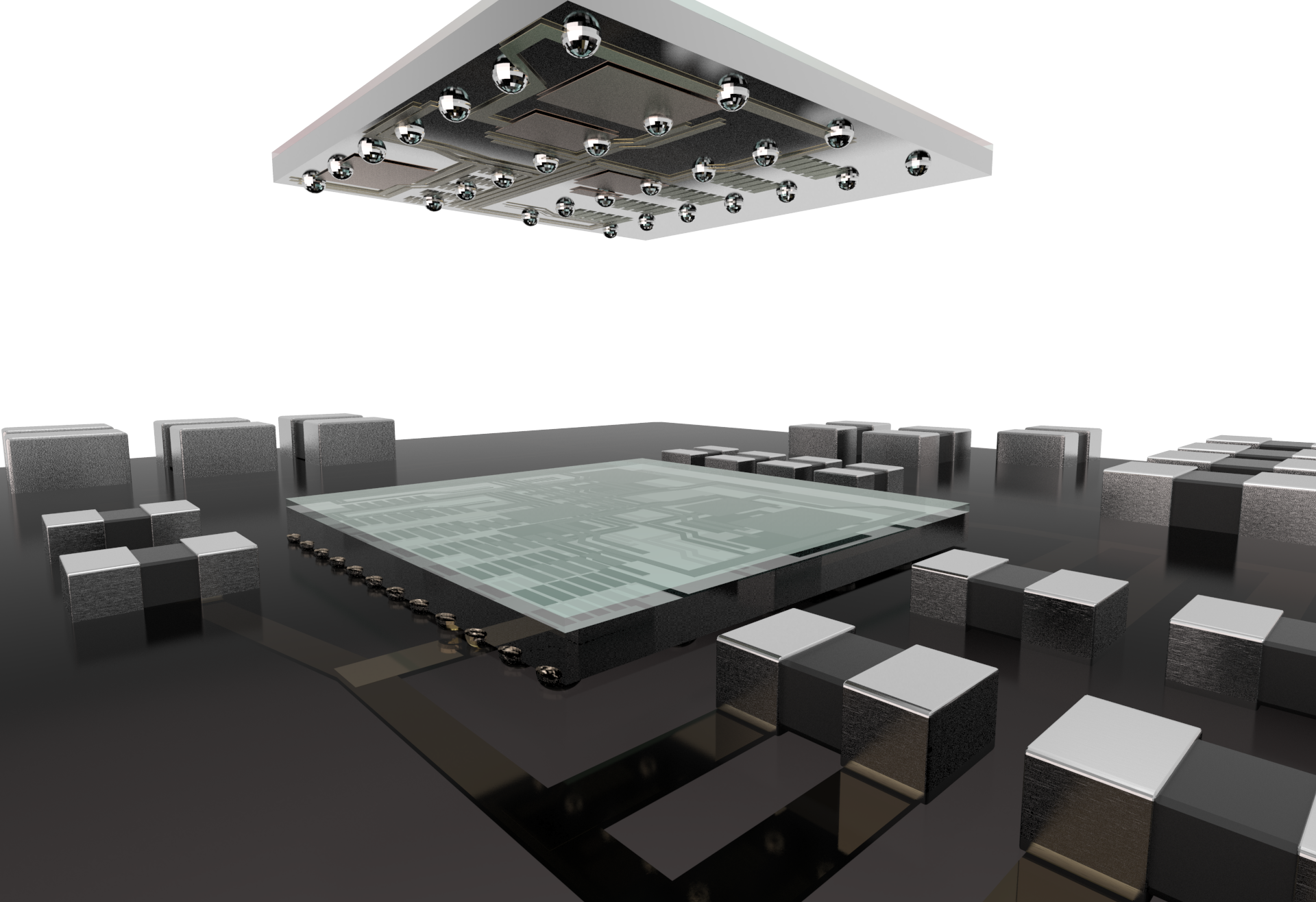

The industry leading placement accuracy of ±15 um delivers accurate placement to position small parts and parts with fine bumps just on the circuit.

This heightened accuracy mode can be specified per part, which keeps the impact on tact time to a minimum.

*NXT III(c) with H24S and H24A heads

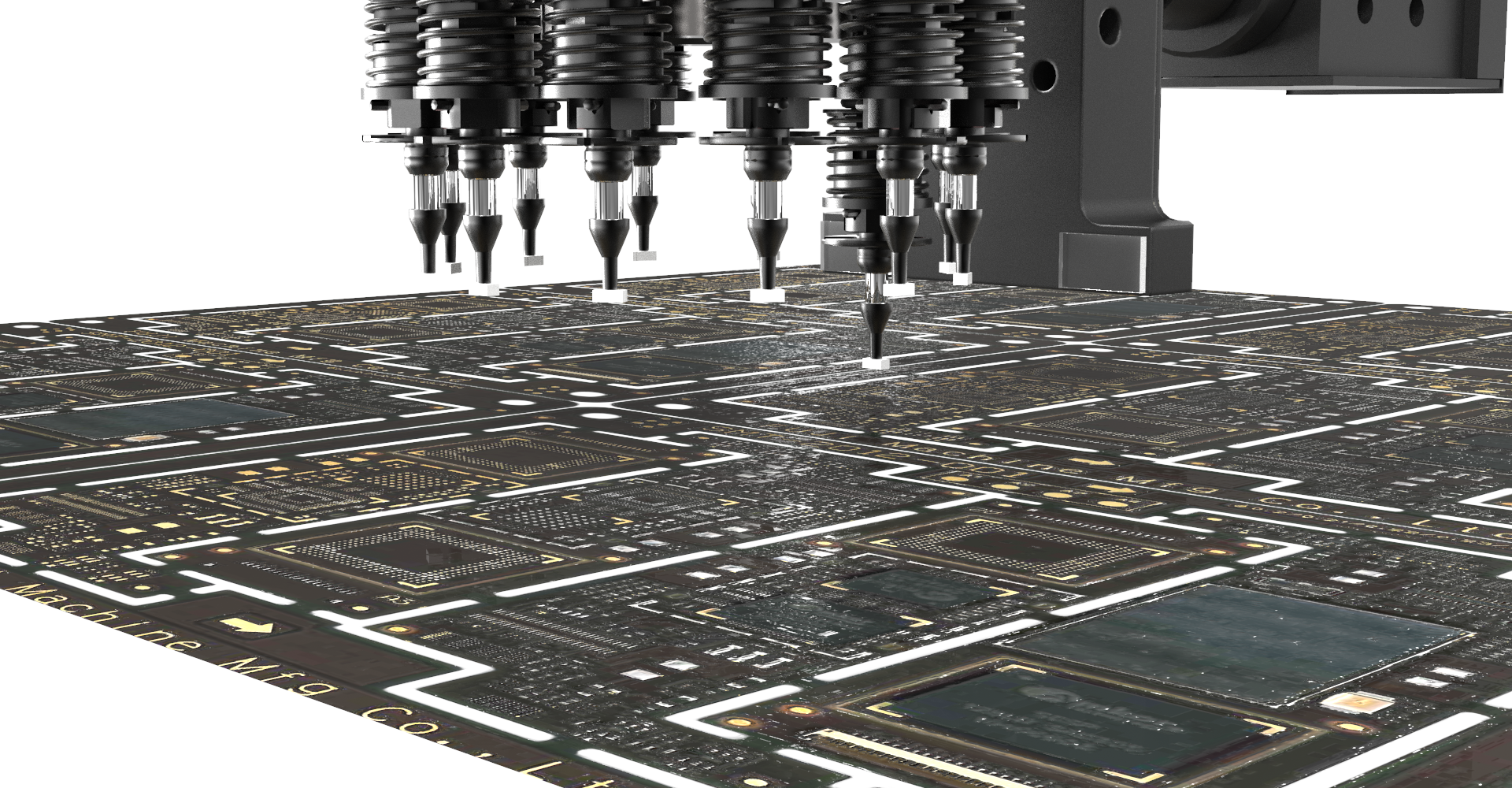

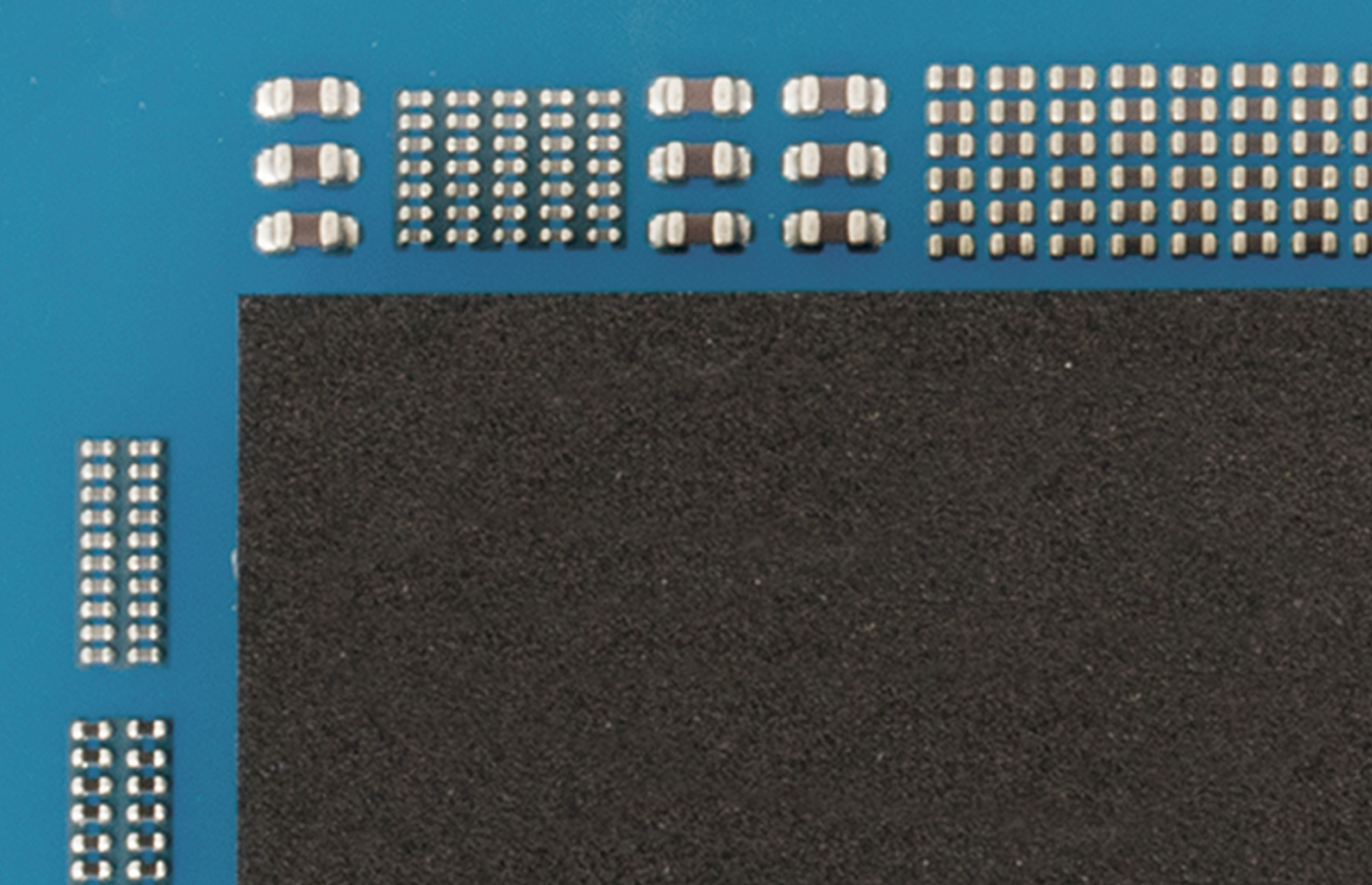

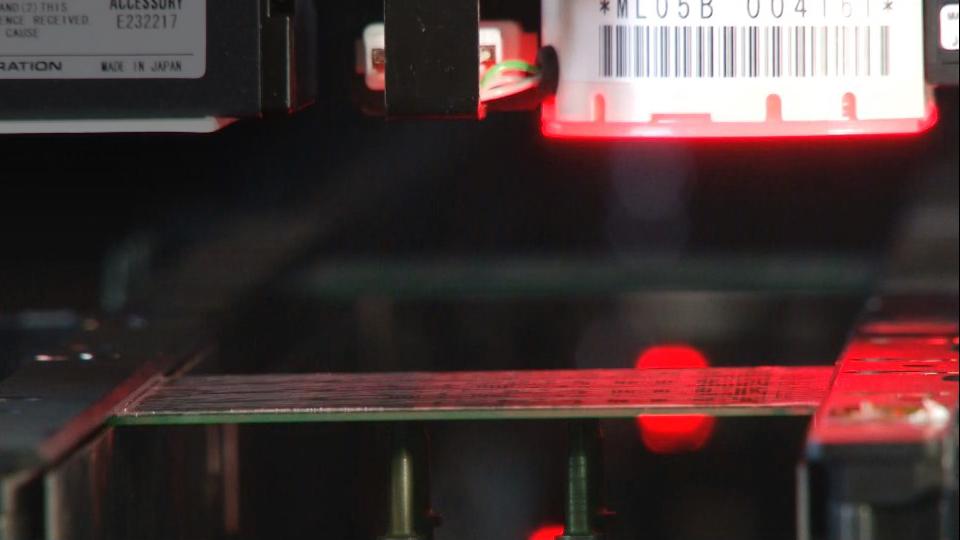

With highly accurate recognition technology driven by our independently developed vision processing camera and LED light source with fine lighting patterns, we are able to support 0201 mm (008004") sized parts and other cutting-edge parts that have very small bumps such as WLCSP.

Especially for WLCSP, bumps are recognized exactly to produce accurate placement of parts, which is not likely under ordinary recognition that captures undesirable circuit patterns as well.

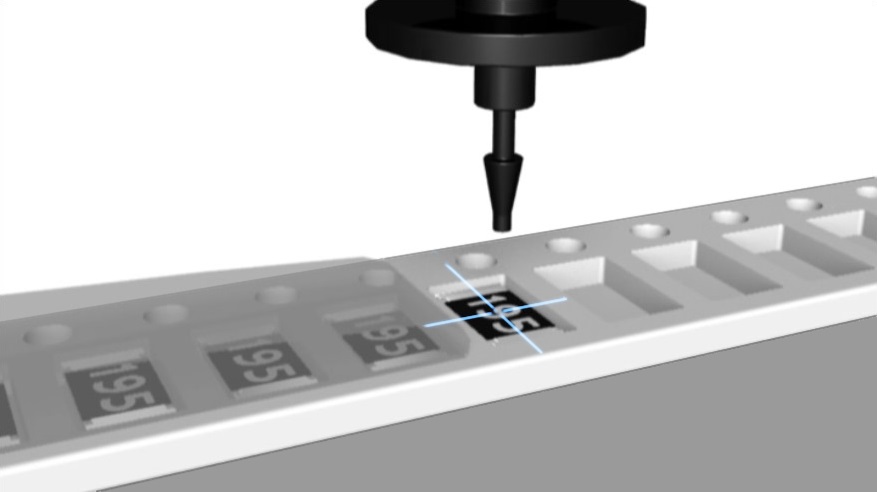

Fuji's original acceleration and deceleration control reduces vibration of parts inside cavities, supporting stable pickup from part supply.

Its durable rotating shaft structure maintains precise indexing accuracy for the long term.

Stopping and positioning panels is performed without stoppers. This results in a lower impact on the panels and parts compared with stopping panels using a stopper. Accordingly, it is possible to prevent parts with a low tacking force and unbalanced parts from deviations and excessive tilting respectively.

The machine automatically recognizes slight position changes and individual differences resulting from head exchange, and corrects the placement accuracy (X, Y, Q). The accuracy is corrected by the machine itself and there is no difficult adjustment necessary to be performed by engineers.

*Dedicated jigs are required depending on the calibration methods.

The amount of deformation of the machine due to the heat generated during machine operation is measured and compensated automatically for the pickup and placement positions.

This ensures high accuracy in part placement regardless of the room temperature and production time of the day.