In recent years, with the rapid progress of electrification of automobiles, there have been significant changes in the composition and performance requirements of electronic boards. The impact of functional integration is particularly significant, with an increasing number of parts of various sizes and shapes, ranging from very small parts to large parts, being mixed on a single panel.

Under these circumstances, the following advanced support is strongly required for pick and place machines.

- Functions for maintaining stable quality

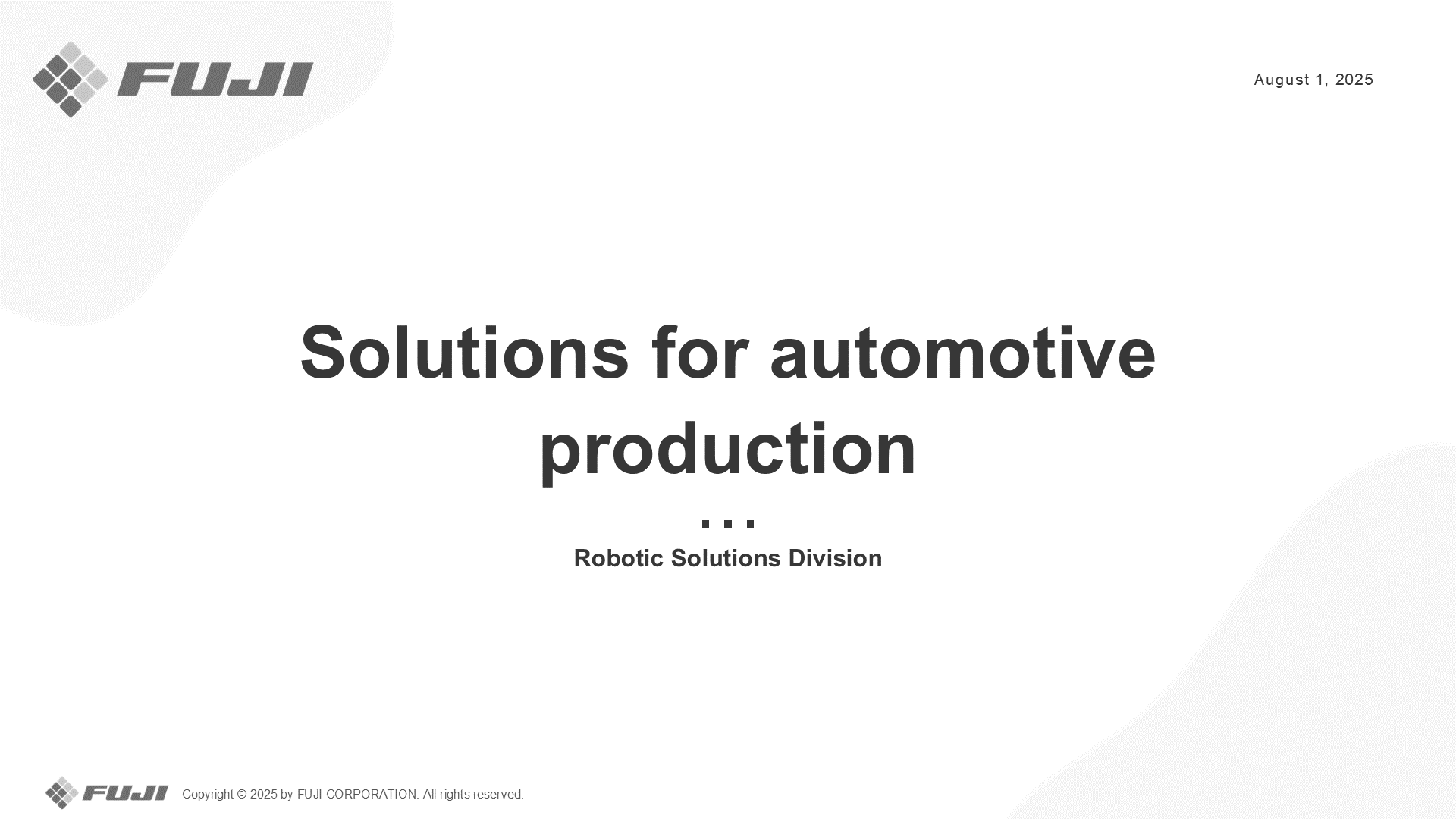

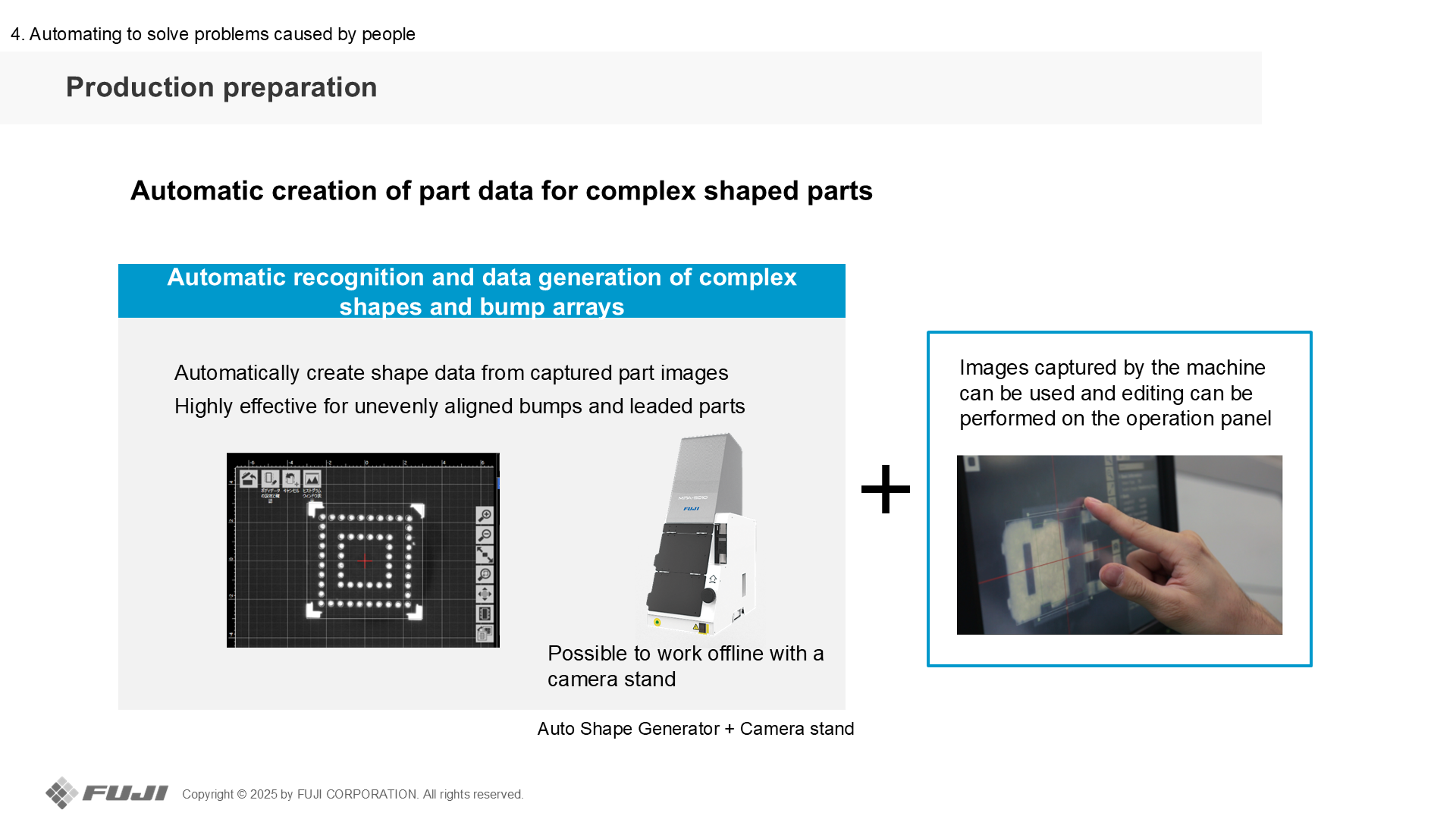

- Flexibility to handle a wide variety of part sizes and shapes

- Ability to respond quickly and accurately to irregular events

The introduction of machines that meet these requirements is an important factor in maintaining and improving product competitiveness.

However, the new risk factor that has emerged for achieving both high levels of quality and productivity is human influence.

We offer industry-leading automation solutions as one of the solutions to these human-related challenges.

| Production preparation |

|

|---|---|

| Offline changeover |

|

| Online changeover |

|

| Production |

|

| Maintenance |

|

This document has some typical solutions that support and replace human work for each production process.