Consistent highly rigid machine design from the base to printing section enables stable, high accuracy printing at the top of its class. An Intelligent Screen Printer that delivers both speed and usability.

Consistent highly rigid machine design from the base to printing section enables stable, high accuracy printing at the top of its class. An Intelligent Screen Printer that delivers both speed and usability.

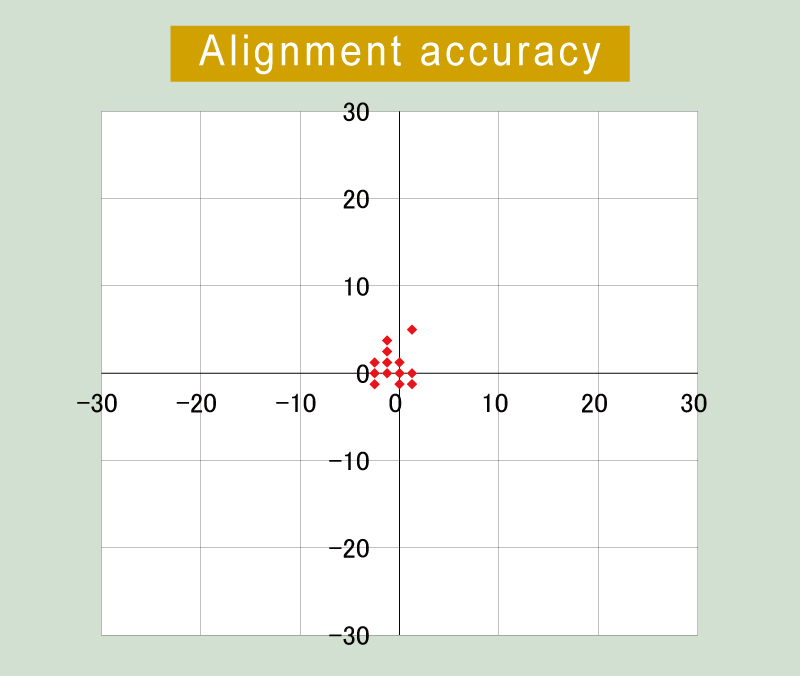

Highly rigid design and stable position correction mechanism enable a highly accurate repetitive panel alignment accuracy of 10 μm (6σ Cpk ≥ 2.0).

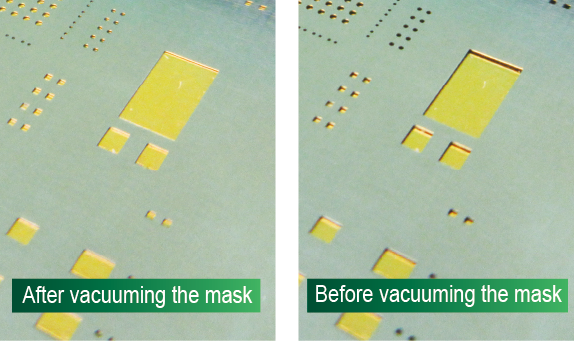

By using vacuum pressure to secure the metal stencil from the underside and keeping it in close contact with the panel, deflection of the metal stencil during printing is prevented and stable print quality can be maintained.

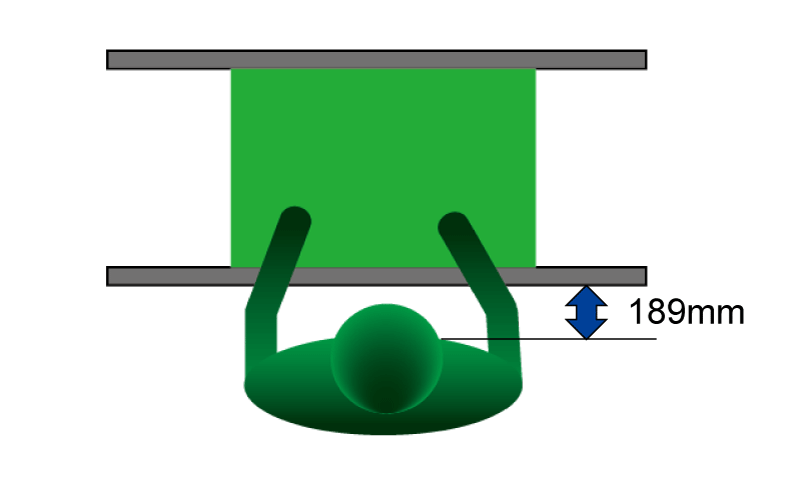

Stable clamping is achieved by using hybrid clamping*, which allows users to select the optimum clamping method (side clamp/top clamp/edge clamp) according to the characteristics of the panel.

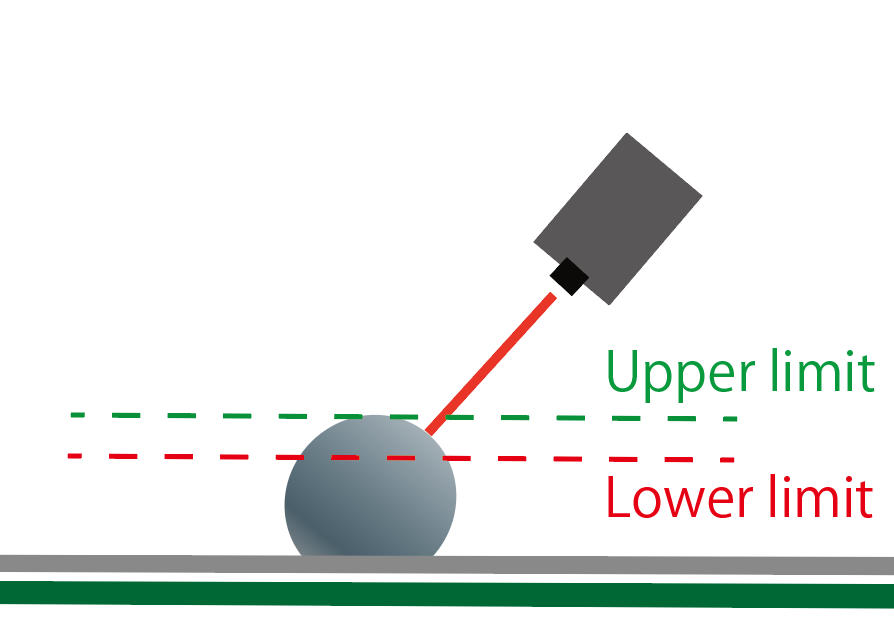

Unevenness along the panel and stencil are detected in real time using a load cell attached to the squeegee head, and the pressure is controlled so that it remains uniform during printing.

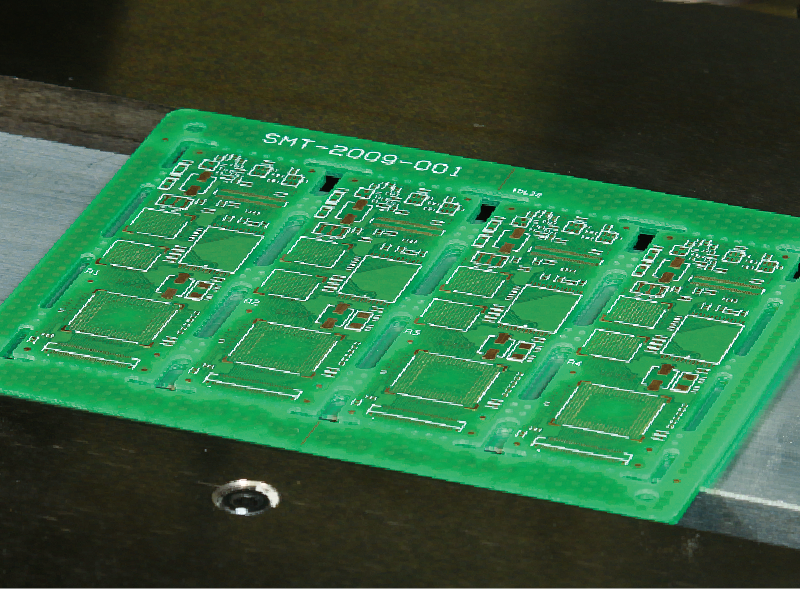

The backup pins are positioned automatically at the locations specified in the production program.

This reduces workload required for changeover, preventing defective panels resulting from human error.

After print operation the volume of solder is measured, prompting solder to be supplied when required. This means that the solder roll is kept at the optimal diameter for stable printing quality.

The IDs of the materials used in production are verified against the IDs of the materials specified in the production program, preventing the use of the wrong materials.

It is possible to choose between two methods; using the data from Integrated Production System - Nexim, or using the data stored in the GPX-CII itself.

Applicable materials: Solder, metal stencil, backup block, squeegee

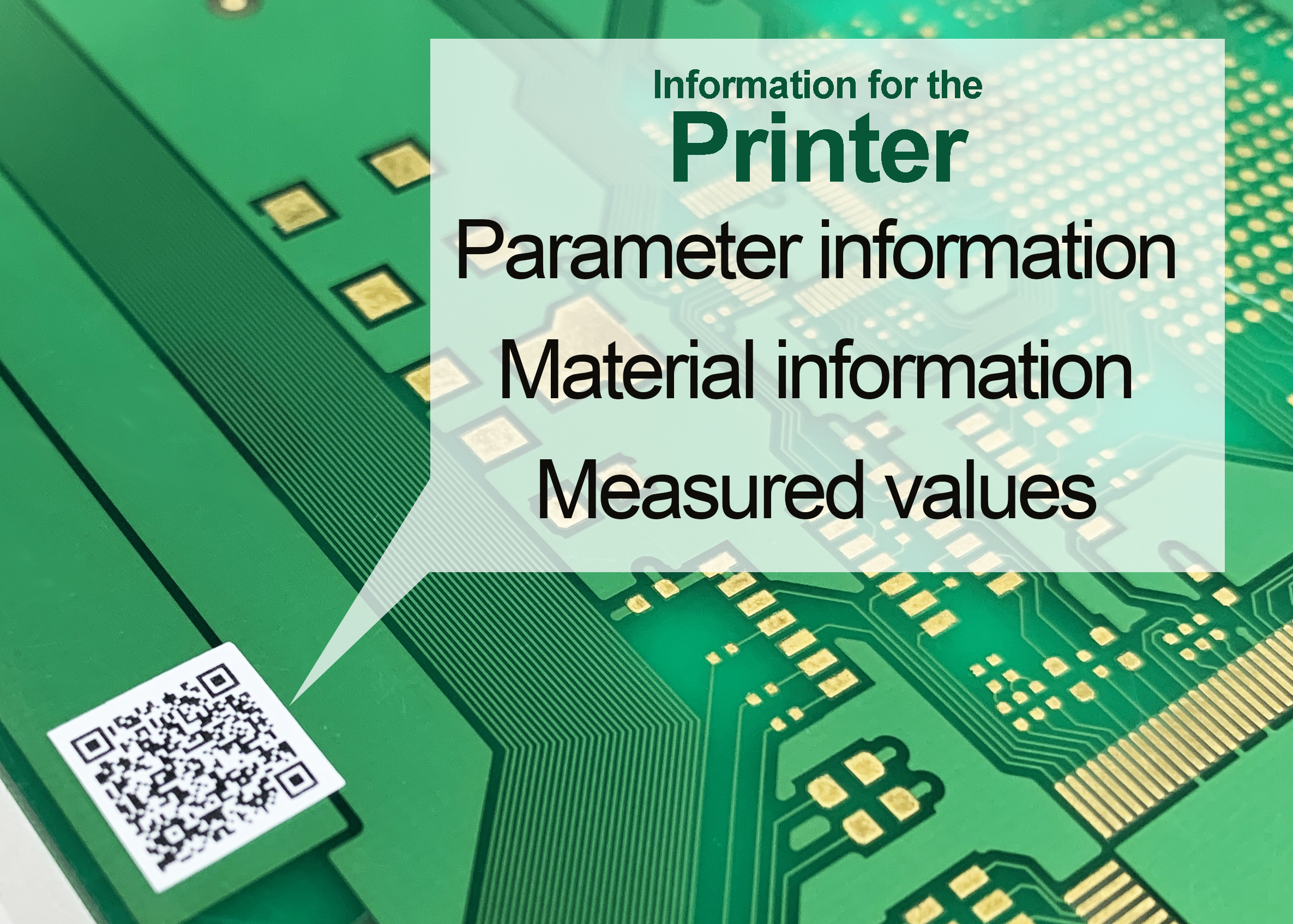

Traceability data can be acquired for each panel ID.

It is possible to choose between two methods; using the data from Integrated Production System - Nexim, or using the data stored in the GPX-CII itself.

Inspection results are received from the SPI, and the appropriate response to trends that show a change in conditions can be performed automatically.

Because changes such as positional deviations and smeared or missing solder are responded to before they lead to problems, high-quality solder printing is maintained.

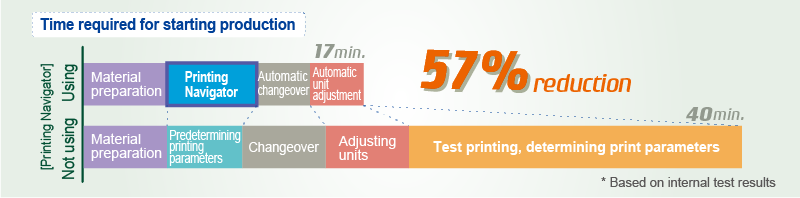

The printing parameters are extracted from the database, giving the optimal printing conditions. The difference in work times between operators of differing levels of skill and experience is eliminated, reducing the time taken to start production.

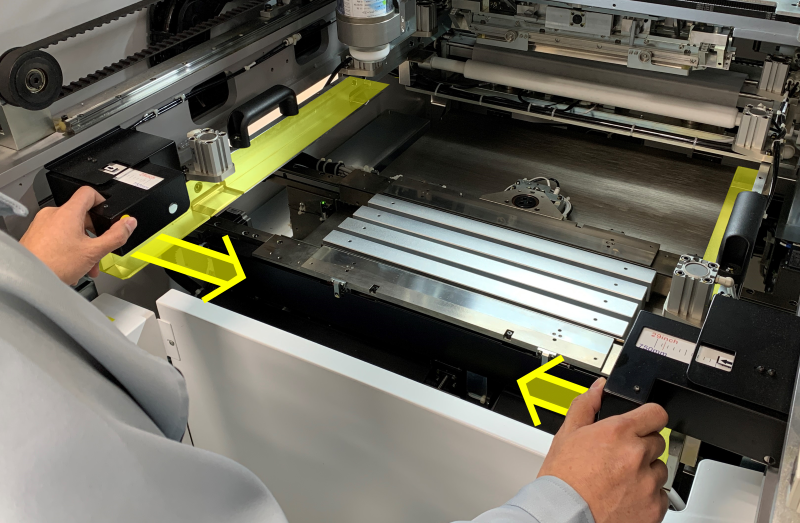

The width of the metal stencil frame can easily be changed to match the size of the metal stencil.

With the slide mechanism there is no need for dedicated adapters, reducing the amount of preparation work required when producing panels with differing stencil sizes on the same line.

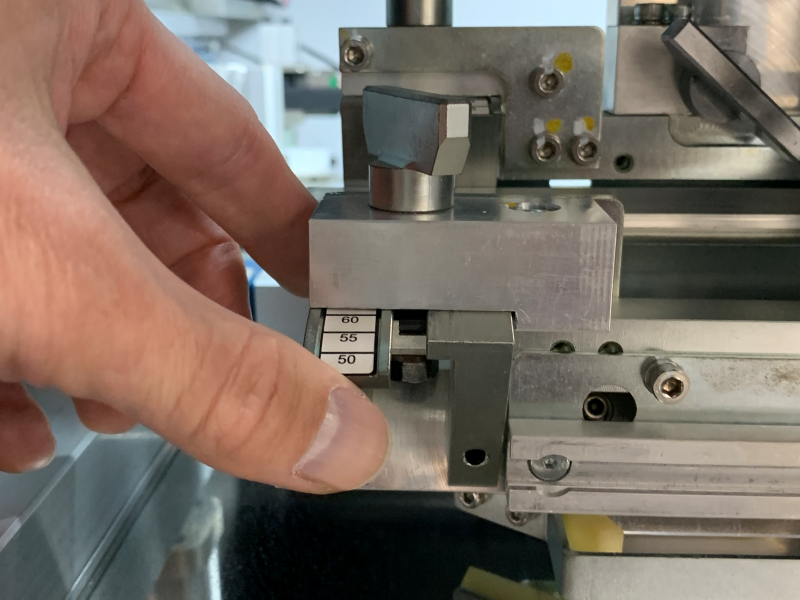

The angle of the squeegee can be easily adjusted against the indicators on the squeegee holder, without needing to remove the squeegee.

The machine has a front cover that provides easy access, reducing the load placed on operators during changeover and resupply.

Asterisks (*) denote option functions

Some functions are not supported on GPX-CSII and GPX-CL.

Contact Fuji for more details.

| GPX-CII | GPX-CSII | GPX-CL | |

|---|---|---|---|

High versatility for supporting a variety of panel sizes

|

A compact printer that supports dual-lane production

|

Support for producing extra-large panels

|

|

| Panel size | 48 x 48 to 610 x 610 mm Thickness: 0.4 to 6.0 mm, 0.3 mm *Option |

48 x 48 to 380 x 610 mm Thickness: 0.4 to 6.0 mm, 0.3 mm *Option |

80 x 80 to 850 x 610 mm Thickness: 0.4 to 10.0 mm |

| Repeated alignment accuracy | ±10 um, 6σ, Cpk ≥ 2.0 | ±10 um, 6σ, Cpk ≥ 2.0 | ±10 um, 6σ, Cpk ≥ 2.0 |

| Panel loading time | 6.0 seconds | 6.0 seconds | 10 seconds |

| Metal stencil frame size | 29 x 29 inches, 750 x 750 mm, 750 x 864 mm 550 x 550 to 29 x 29 inches, adjustable type |

29 x 29 inches, 750 x 750 mm, 750 x 864 mm 550 x 550 to 29 x 29 inches, adjustable type |

1050 x 864 mm 29 x 29 inches to 1050 x 864 mm, adjustable type |

| External dimensions | L 1,630 x W 1,220 x H 1,475 | L 1,380 x W 1,220 x H 1,475 | L 1,754 x W 1,540 x H 1,465 |

| Weight | 1,300 kg | 1,250 kg | 1,450 kg |