To ensure that supplying tray parts does not become a bottle neck – Large capacity tray unit proposal –

As smartphones, automotive ECUs, and industrial equipment become increasingly sophisticated, the parts placed are shifting toward larger, higher-performance parts.

In particular, large CPUs, power devices, high-heat/high-power ICs, and multi-pin, advanced-function ICs, which are supplied from trays, tend to increase in size as equipment performance improves.

As electronics devices become increasingly smart, the electronic parts used are experiencing a polarization, with both miniaturized parts and larger parts increasing simultaneously. Among these, larger parts—due to their shape and size characteristics—are primarily supplied from trays. As a result, the quantity of trays used is rising, and the operating rate of tray parts supply units is also increasing.

Challenges in supplying large parts

- Fewer parts set on a single tray

- More frequent replenishment due to rapid consumption

- Machines must be stopped each time parts are replenished

Frequent part replenishment

Large parts, in particular, have a high unit cost, and panels using these parts carry significant added value per unit. When such a production line stops, expensive parts and work-in-progress parts remain in the production line, and the loss in production opportunity becomes substantial—an impact that cannot be ignored. This is why a stable supply system that prevents line stops is essential for improving productivity.

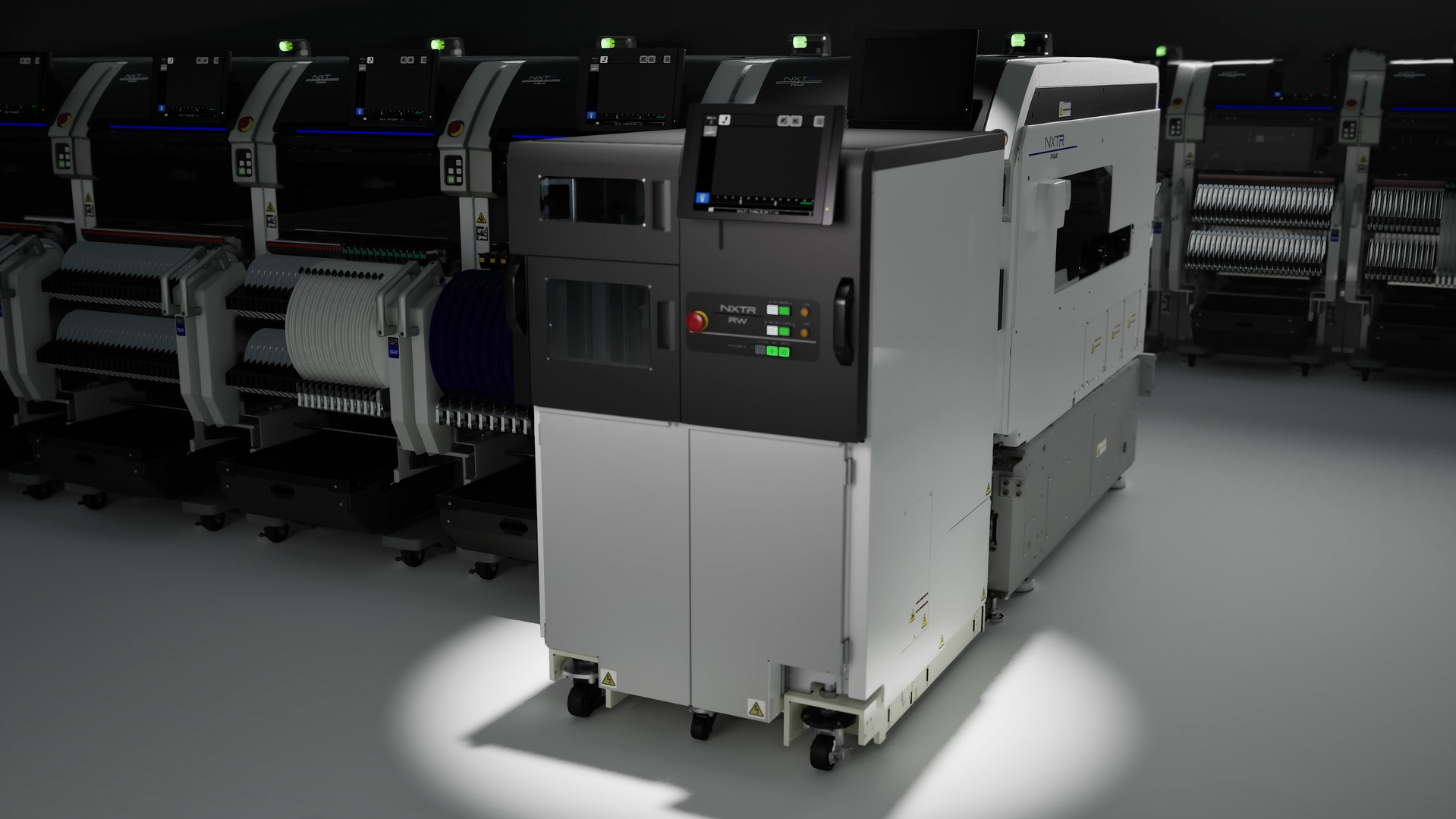

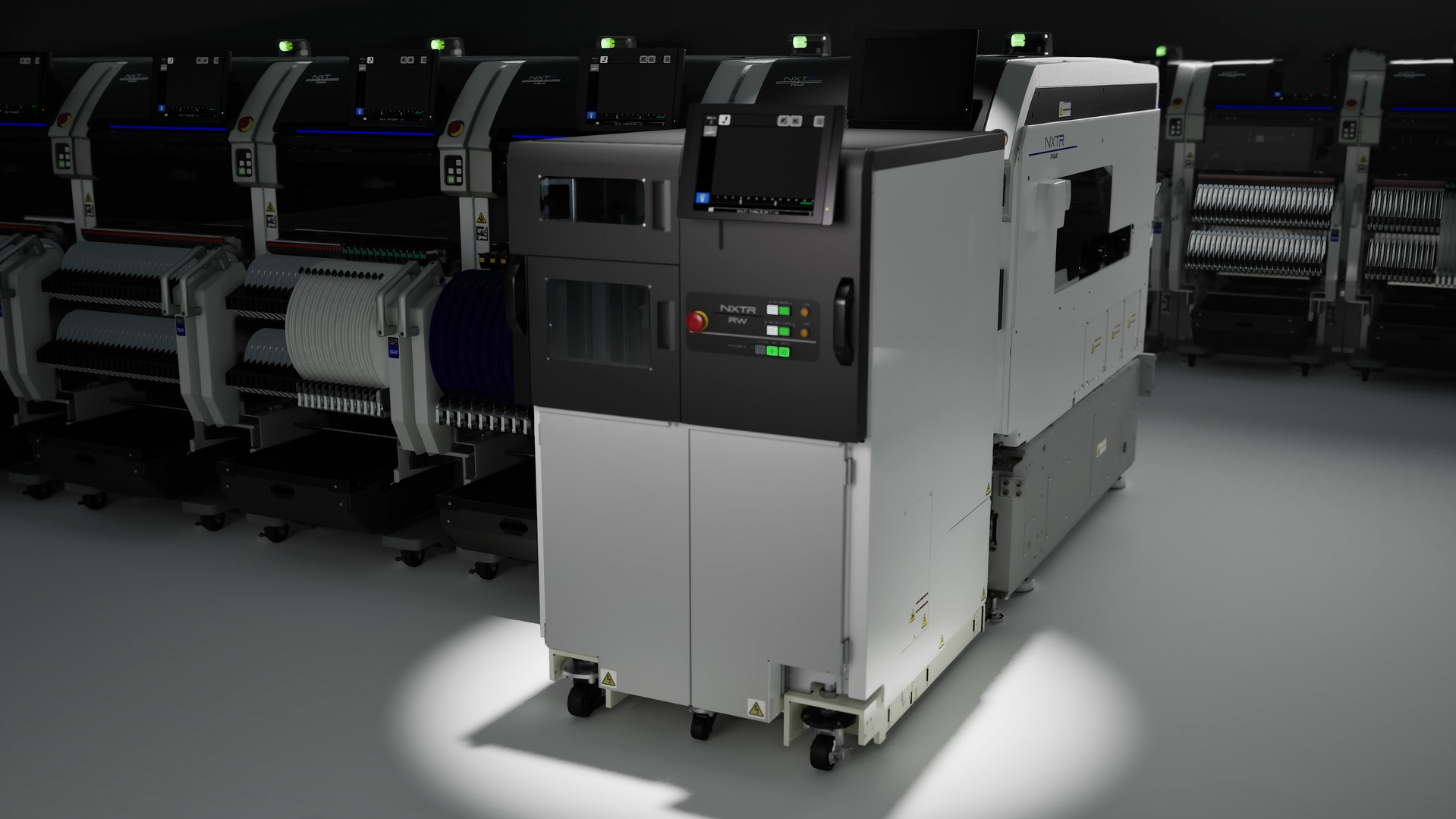

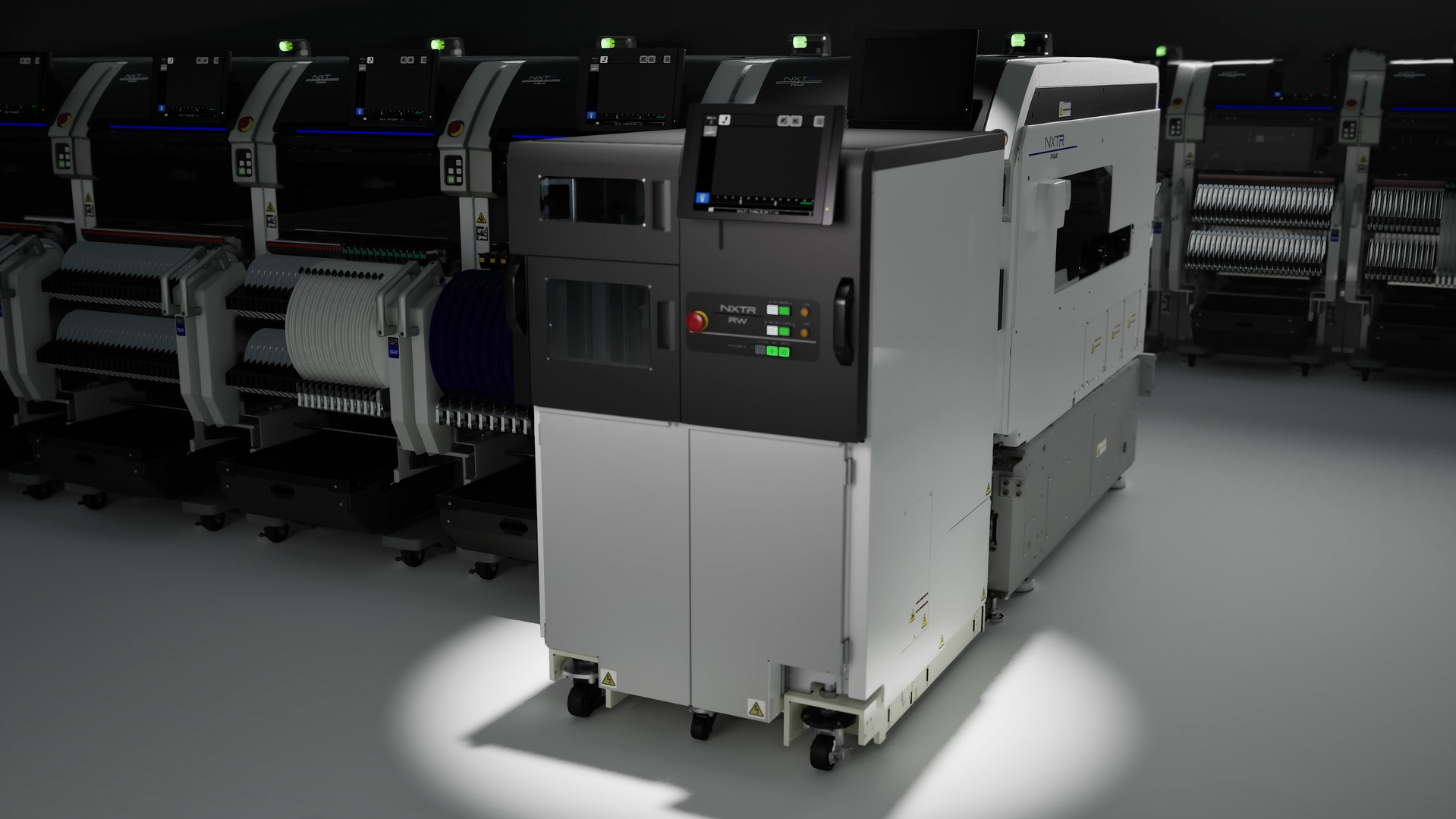

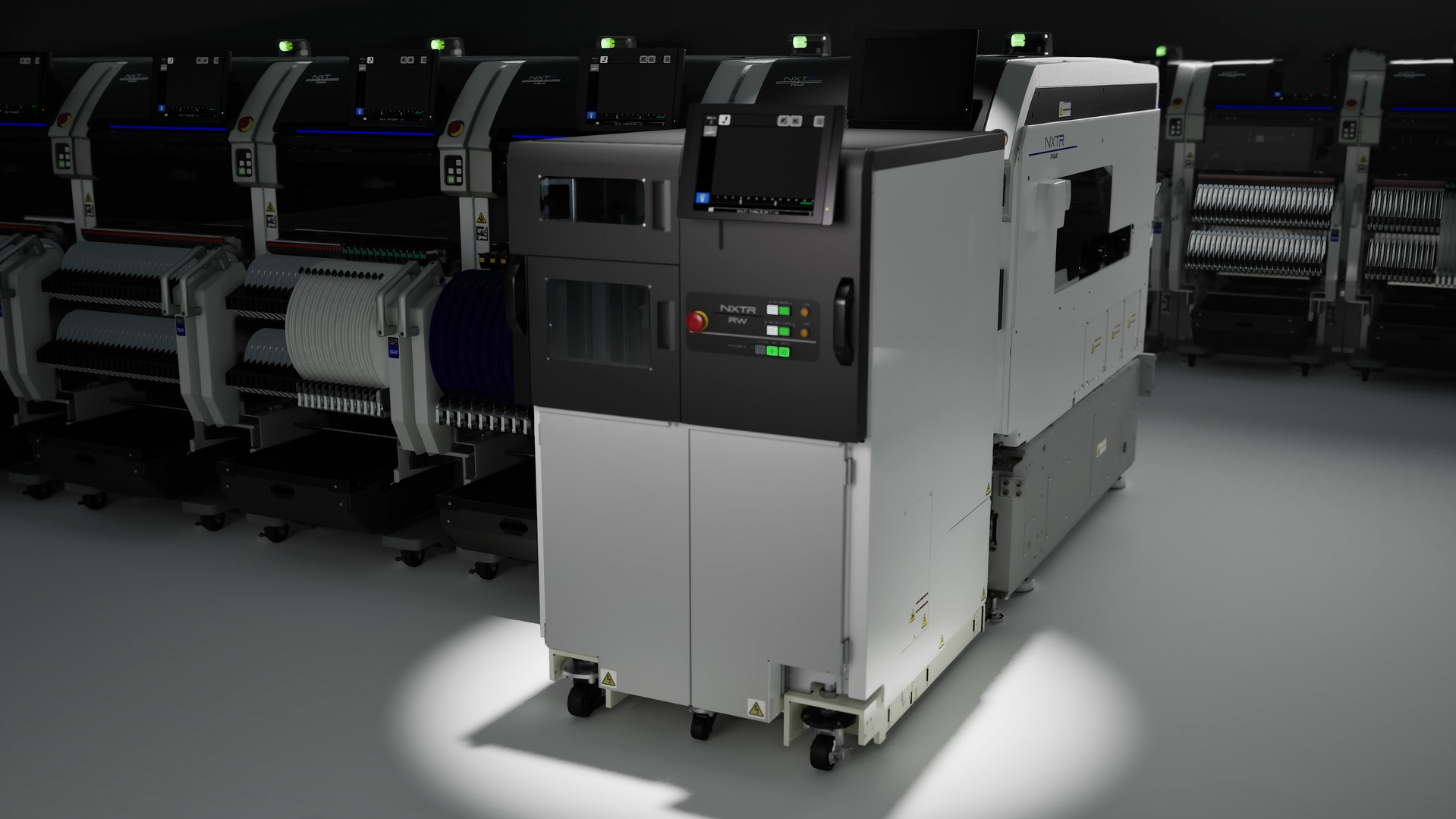

The tray unit-RW has the following three features, addressing the large tray part issues and supporting stable operation.

1. Large capacity (up to 69 drawers, 138 trays)

2. Part resupply without stopping production

3. Automatic changeover inside the unit

These features are detailed in the following slides.

A high-capacity supply unit is essential for stable production with large parts because the quantity of parts that can be set in a tray is smaller for large parts. The tray unit-RW has an overwhelming capacity of loading up to 69 drawers for 138 trays, allowing large parts of various types to be set collectively for one shift or one day.

This results in...

- Drastically reduced resupply frequency

- No need to stop the machine

- Significantly reduced operator workload

Operation with all large parts loaded is possible.

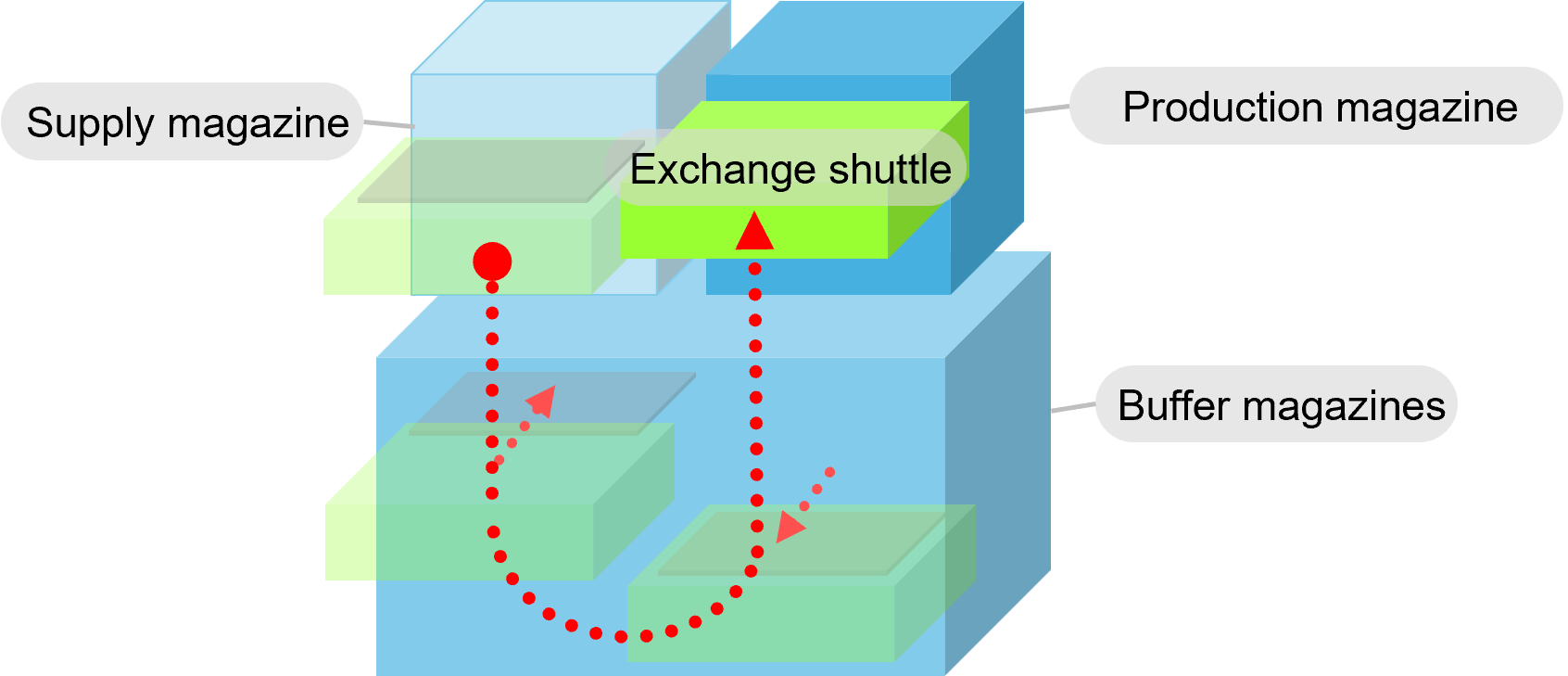

Production continues while parts are being supplied from the supply magazine to the production magazine.

In addition, operators can supply parts while production continues.

With this feature,

- Parts can be supplied at any time

- No need to stop production for part supply

Operators no longer need to wait in front of the machine to replenish parts, which frees them from replenishment work.

This enables a shift from machine-scheduled replenishment to operator-controlled replenishment.

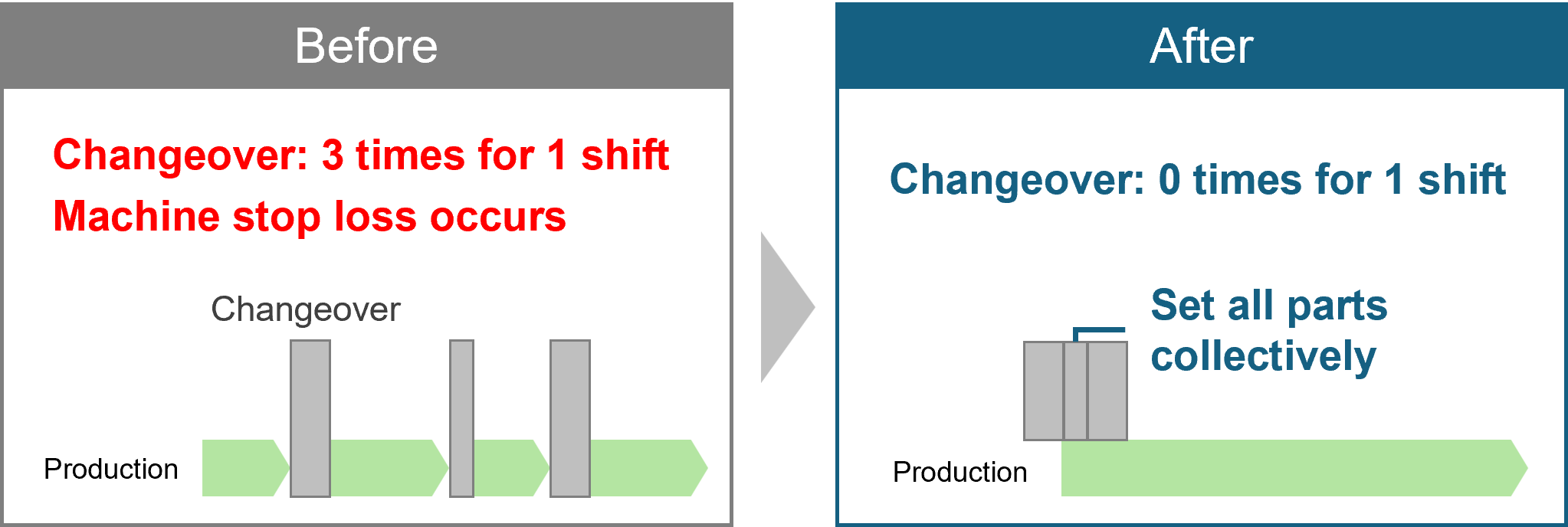

The tray unit-RW supports automatic changeover within the unit.

By setting the parts required for the next production in advance, changeover is performed automatically—without operator intervention.

Changeovers can be a significant burden on operators when performing high-mix production or when using large parts. With the tray unit-RW, operator workloads are reduced, and production line downtime is minimized.

Trays are automatically changed with the exchange shuttle

Before: Changeover: 3 times for 1 shift

After: Changeover: 0 times (no machine stops)

➜ Increased work flexibility and smoother production

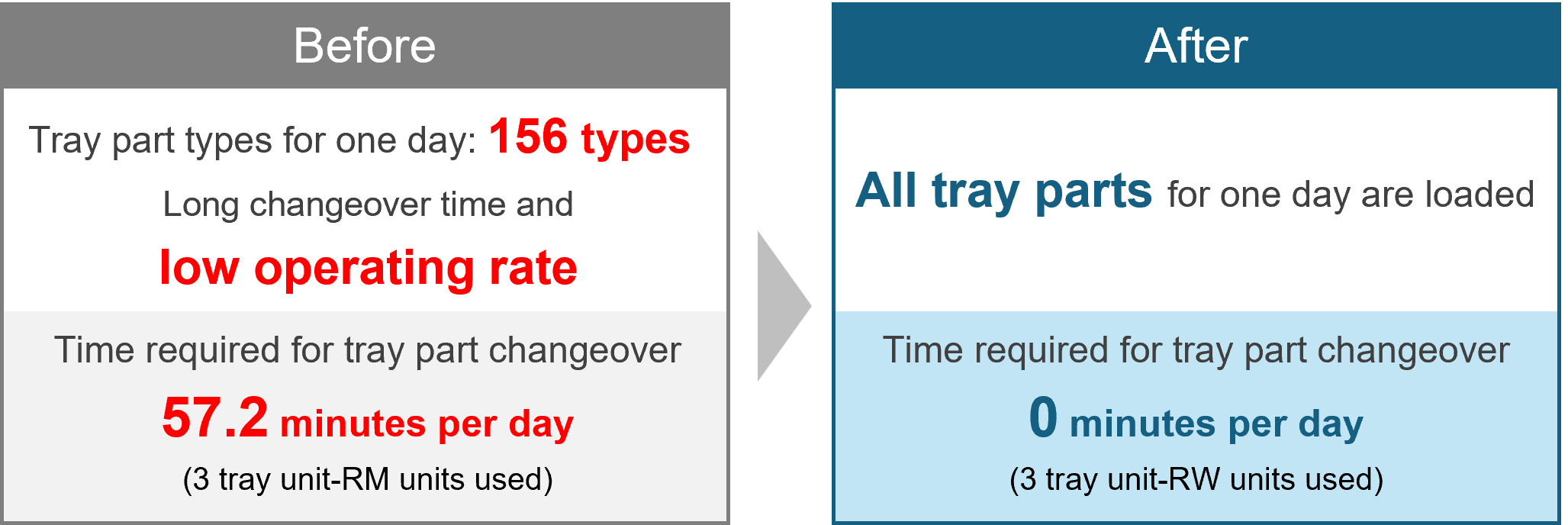

Before introduction: Changeover work: 57.2 minutes per day (as all parts cannot be loaded at once)

After introduction: Changeover work: 0 minutes per day

➜ Maximized operating rate + zero workload

The tray unit-RW delivers greater efficiency for production sites using a higher ratio of tray parts.

Large parts are the core of the product, but at the same time, they are a risk factor that can easily cause production stops. The tray unit-RW eliminates that bottleneck with its large capacity, replenishment without stopping production, and automatic changeover.

With the increasing number of large tray parts and growing labor shortages, now is the time to introduce the tray unit-RW into your production. The tray unit-RW helps ensure stable operation of your production lines.

For a clear overview of product features and basic specifications, visit the link below to learn more.