In recent years, the diversification of market needs has led many production sites to adopt a production system that supports high-mix, low-volume production.

However, many people are working on trying to make improvements because the time taken for changeover is longer in high-mix production compared to mass production which leads to increased stop losses.

Requirements for changeover at high-mix production sites

- Reduced changeover workloads

- Shorter production times

- Reduced loads placed on line operators

Fuji’s Multi Job Line Balancer is a tool that can be used to cater to such requirements.

What is Multi Job Line Balancer?

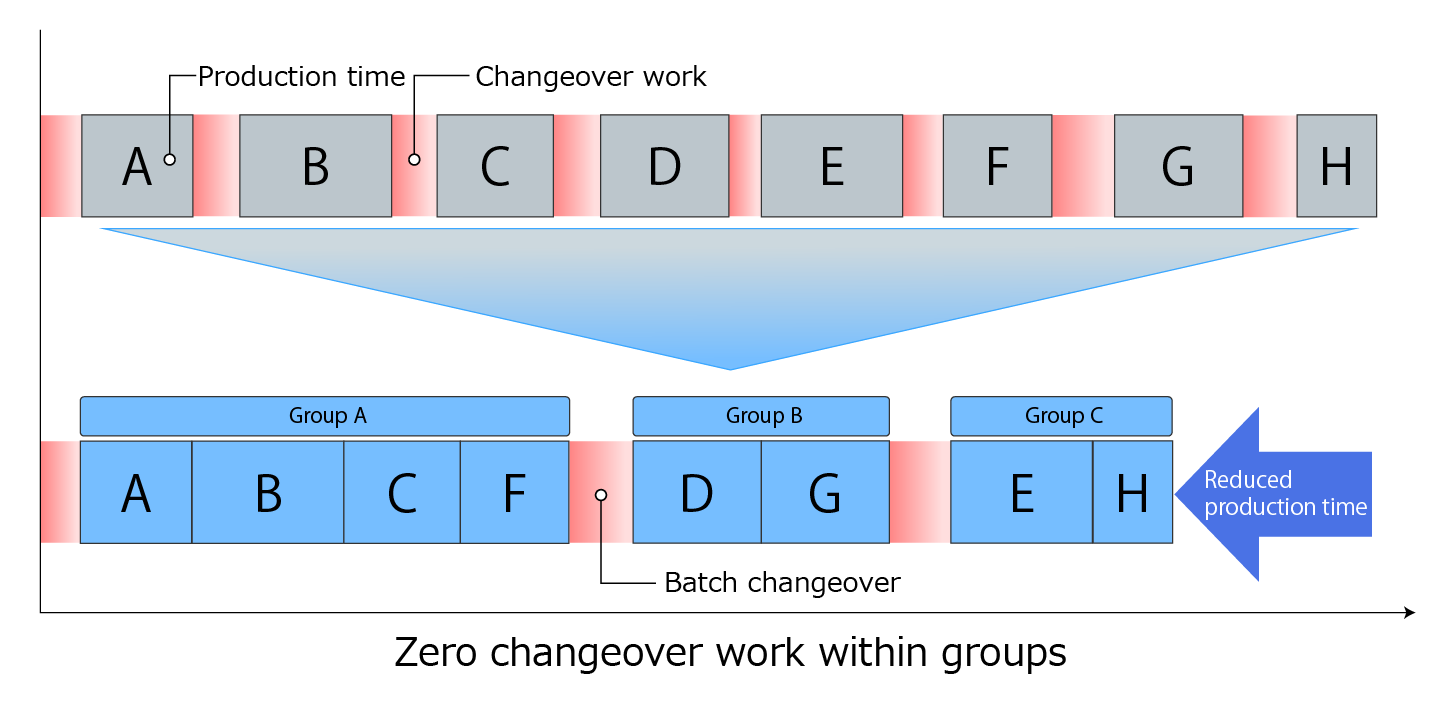

This tool groups together programs with parts that have a high degree of commonality, creates shared feeder setups, and automatically adjusts the production order to ensure the fewest changeovers possible.

It can be used for both when changing out feeders individually, and when performing batch changeover using feeder carts.

Multi Job Line Balancer example

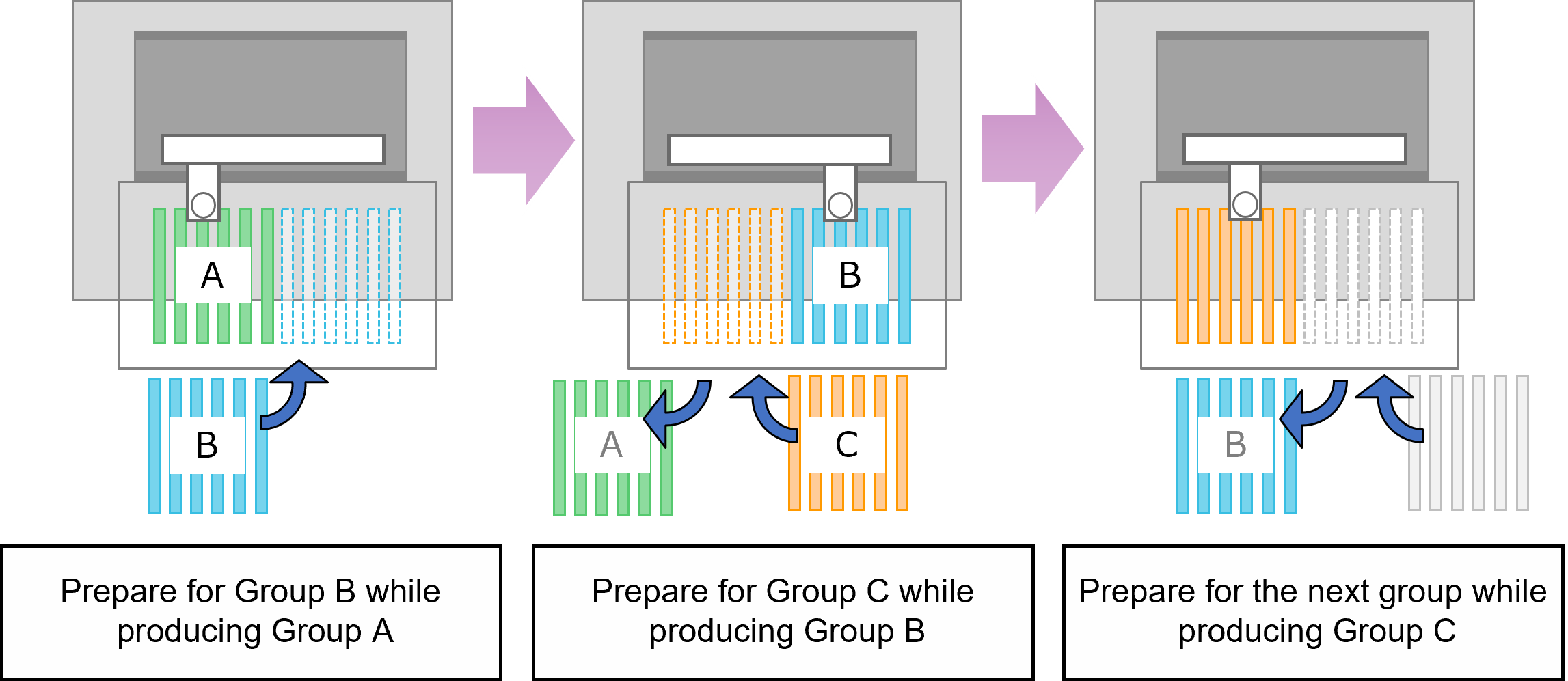

Improve operation rates by setting feeders for the next production during production with AB mode feeder exchange

If the number of feeders to be set per machine is low, the operation rate can be improved by using AB mode feeder exchange, in which each feeder supply unit is divided into two areas, one for production and the other for changeover.

This makes it possible to reduce stop losses because feeders to be set for the next production can be set during the current production.

AB mode feeder exchange example

Multi Job Line Balancer creates a selection of feeder setups with different conditions, so that the user may select the calculated results that best suit the production conditions.

| Applicable software | Nexim, Fuji Flexa |

|---|

Fuji’s support does not stop at handy tools like these. If you require help optimizing your production programs, or have any other improvements you would like to make to your production, our FUJI Kaizen Service team would be more than happy to lend their expertise.

Contact us below for more information or to request an appointment.

About the FUJI Kaizen Service: https://smt.fuji.co.jp/en/service_support/cv

Contact form: https://smt.fuji.co.jp/en/contact/