近年、自動車の電動化が急速に進展する中で、電子基板の構成や要求性能にも大きな変化が生じています。特に機能の統合による影響が大きく、微細な電子部品から大型部品に至るまで、さまざまなサイズや形状の部品が1枚の基板上に混載されるケースが増加しています。

このような状況下では、実装設備に対して以下のような高度な対応力が強く求められます。

・安定した品質を維持するための機能

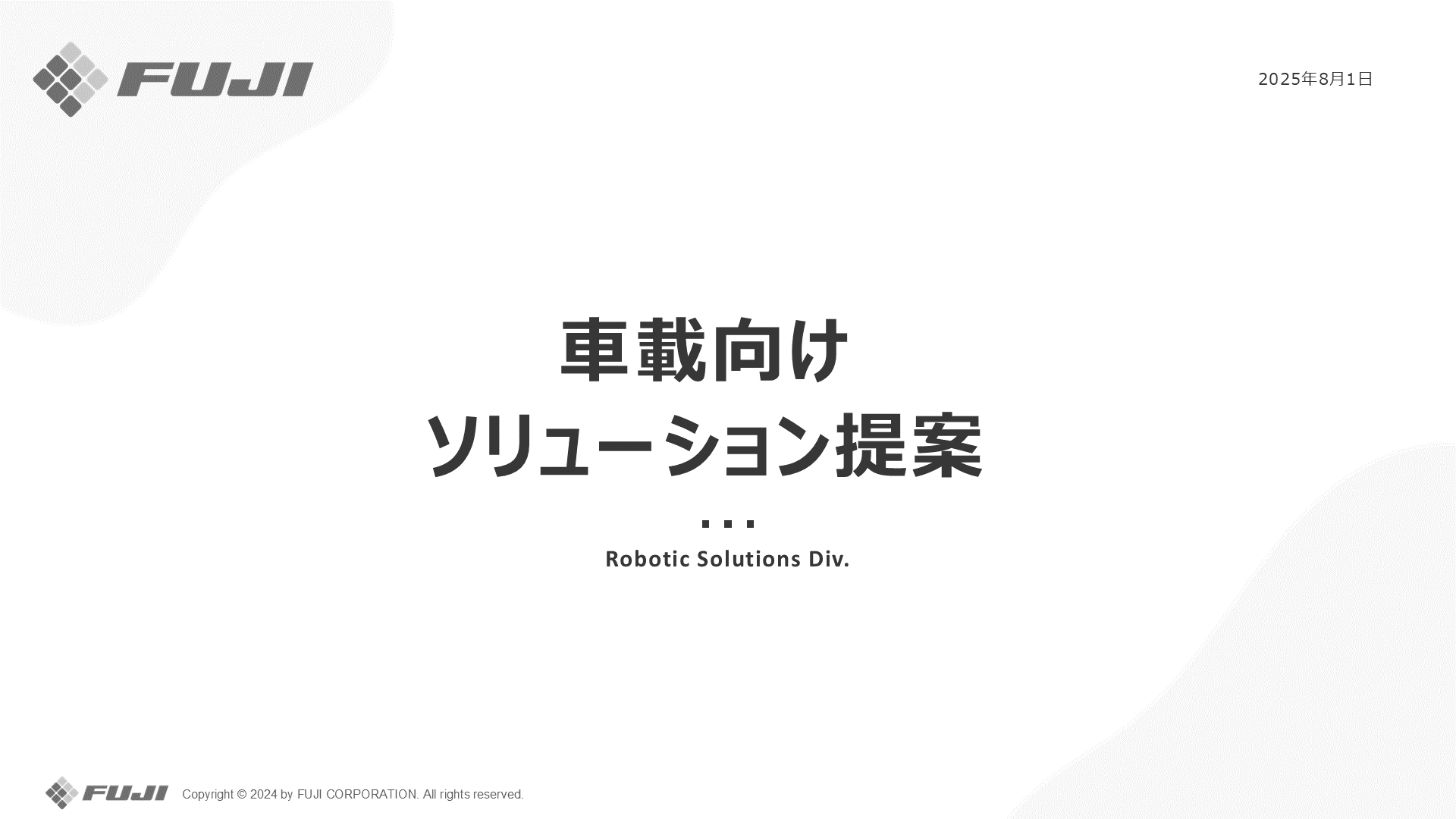

・多様な部品サイズおよび形状への柔軟な対応力

・イレギュラー事象に対する迅速かつ的確な対応力

これらの要件を満たす設備の導入が、製品競争力の維持・向上において重要な要素になると考えられます。

しかしながら、高い水準で品質と生産性を両立するうえで新たなリスク要因として浮上するのが「人的要因」です。

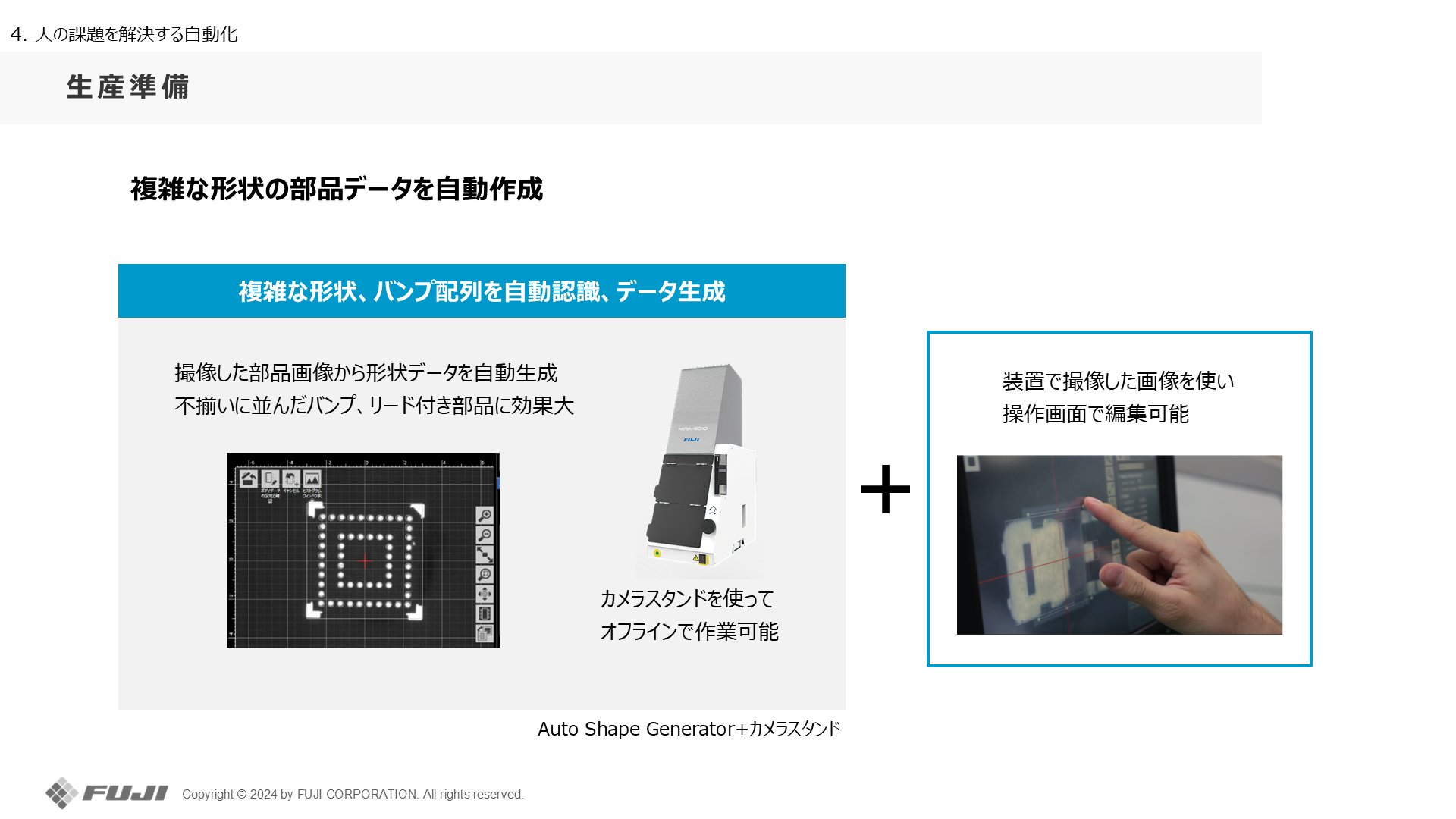

私たちはこうした人に関する課題の解決策の一つとして、業界最先端の自動化ソリューションをご提案しています。

人の作業をサポート、代替するソリューション

| 生産準備 |

|

|---|---|

| 外段取り |

|

| 内段取り |

|

| 生産 |

|

| メンテナンス |

|

本資料では、人の作業をサポート、代替する代表的なソリューションを生産工程ごとにご紹介します。

ぜひご覧ください。