- Efficiency

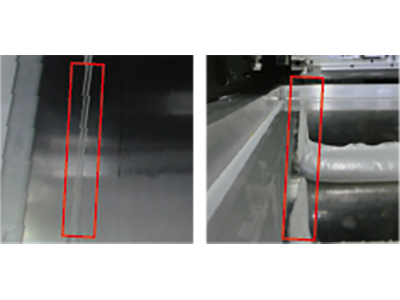

- Quality

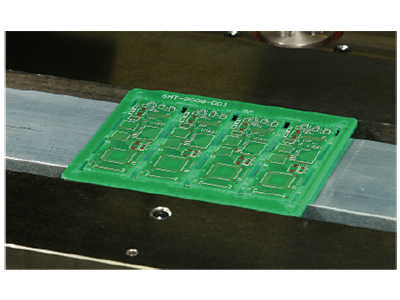

- Screen printing machine

- Smart factory initiative

- Variable-mix variable-volume production

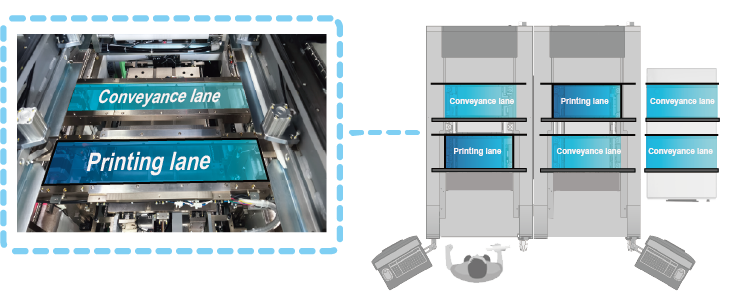

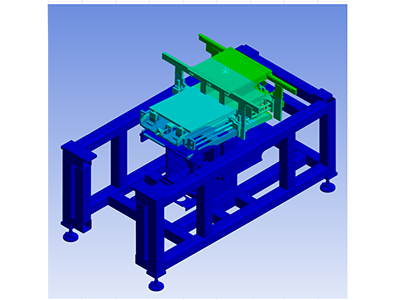

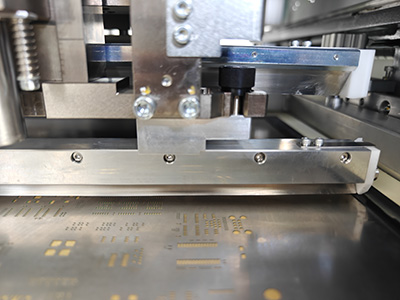

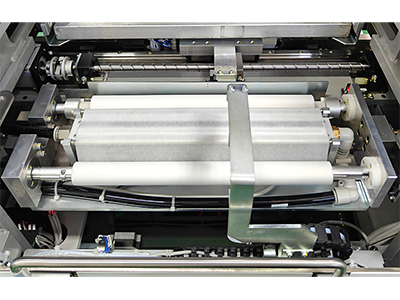

This compact printer offers the high performance inherited from the best-selling GPX series and dual-lane production support to perform a wide variety of production. An optimal line configuration can be made in combination with double conveyor machines that support dual lane production. The length of the machine is shorter than that of conventional machines, and in single lane production, a single unit arrangement provides the highest productivity in the smallest area.