- Efficiency

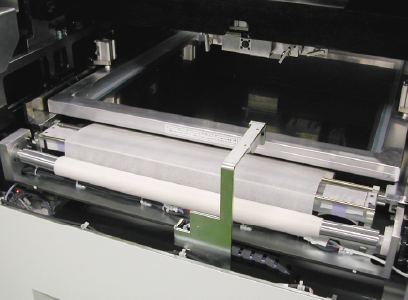

- Quality

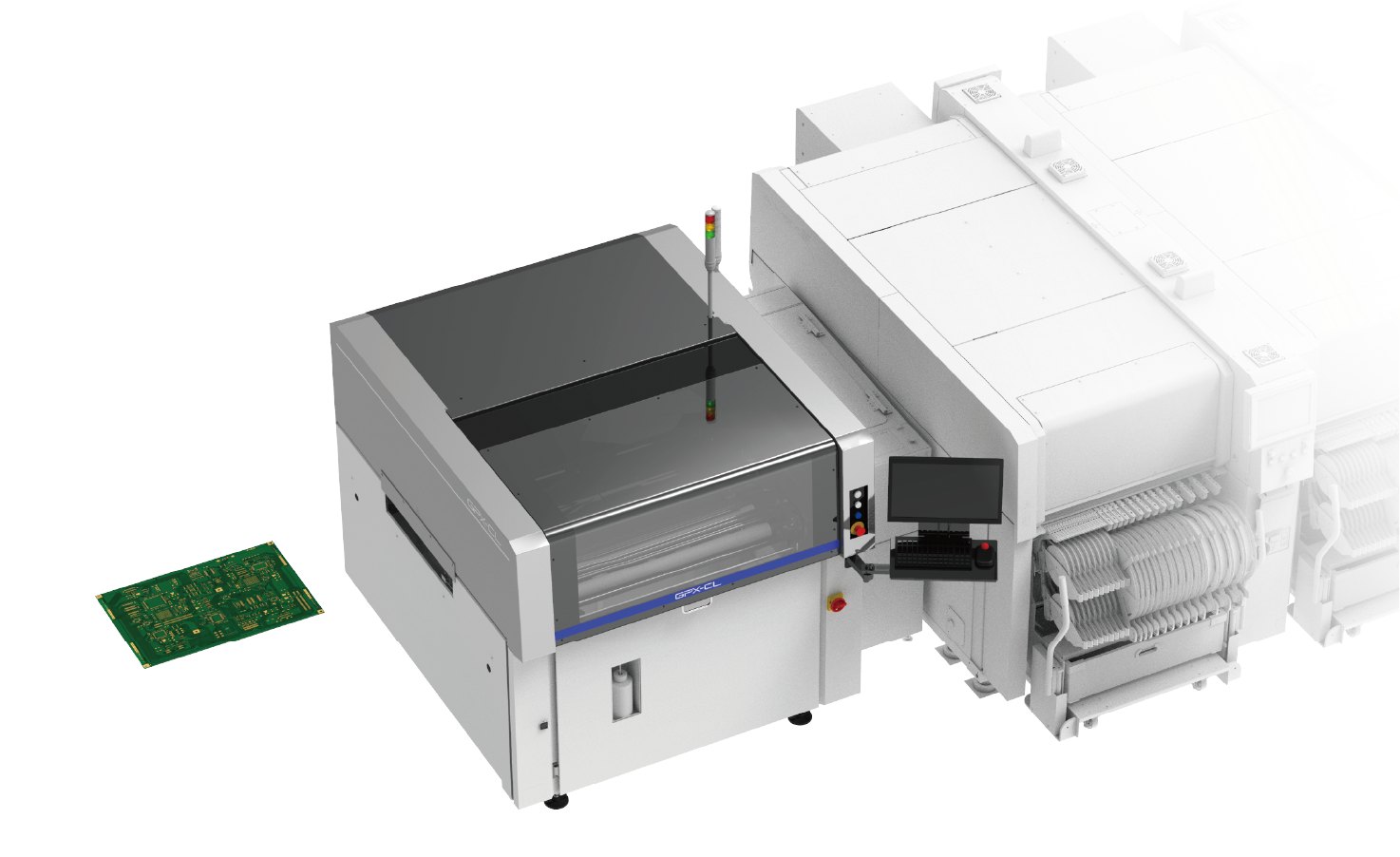

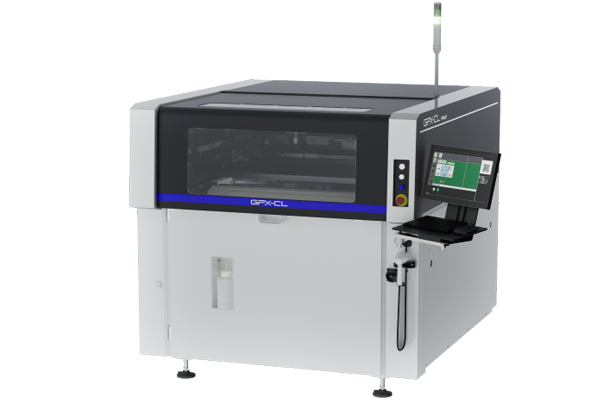

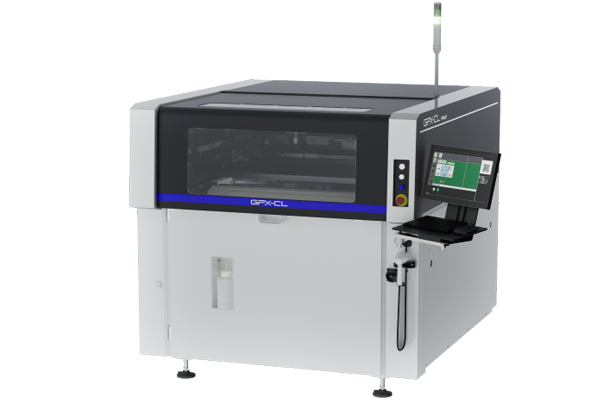

- Screen printing machine

- Smart factory initiative

- Variable-mix variable-volume production

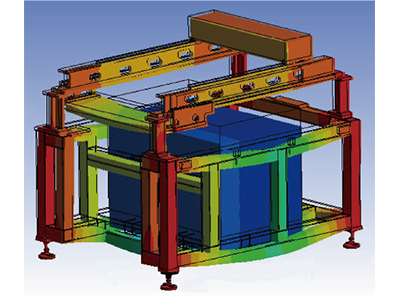

Consistent highly rigid machine design from the base to printing section enables stable, high accuracy printing at the top of its class. This is an intelligent screen printer that delivers both speed and usability. GPX-CL offers superior support for the production of extra-large panels from the GPX series.