An entirely new type of changeover that makes fully automated operation possible - feeder packetized offline changeover - is increasingly being embraced in automated SMT lines

In high-mix production sites, improvement activities have been performed using a variety of approaches to reduce stock and lead time.

Factories with SMT lines are no exception and in particular, reducing feeder exchange time is seen as an effective way to reduce downtime. Therefore, time-consuming work that require checks is separated to offline changeover that is performed offline by people. However, due to factors such as overtime caused by a lack of manpower and the concentration of work on specific people, the rate of errors is increasing, and many managers may be struggling with the fact that improvements are not progressing as they wanted.

Do you have any of these issues for offline changeover work?

- It is troublesome to check the position of feeders when loading feeders and to check whether the position is correct or not.

- It is troublesome to sort the unrequired feeders (parts) from the used feeders and remove them.

- It takes time to search for the available feeders (parts) and collect them.

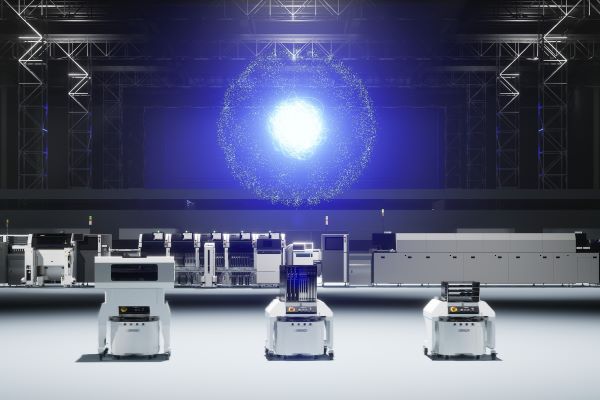

These issues can be solved with "Feeder packetized offline changeover" of the NXTR A model Note 1.

Note 1: The NXTR A model is the latest model of pick and place machine equipped with an automatic feeder exchange system, "Smart Loader".

What is feeder packetized offline changeover?

This is a changeover operation for the NXTR A model, a pick and place machine equipped with an automatic feeder exchange system.

The key point for feeder packetized offline changeover is "optimal role separation between robots, systems, and people".

Both improved productivity and labor savings can be achieved without difficulty by having robots and systems take on work that are prone to human error or take a long time to do in the series of preparation work from offline changeover to changeover.

Feeder packetized offline changeover benefits

Greatly reduces workloads by simplifying feeder preparation work

Setting feeders to pick and place machines is automatically performed by the Smart Loader.

By this, it is no longer necessary to check the loading position of each feeder in offline changeover and workloads can be reduced greatly compared to general offline changeover work.

Work time can be reduced by automating feeder sorting work

The Smart Loader automatically collects only the feeders that are not scheduled to be used from pick and place machines.

In the offline changeover area, the operator only needs to set the collected feeders in an advanced feeder stand Note 2. The work can be completed in a short time because there is no troublesome feeder sorting work.

Anyone can perform work correctly in a short time without any confusion

When the work order to begin preparing is selected, the applicable parts are displayed in a list. When part reels are removed and the IDs are scanned, guidance for the work procedures and the available feeders on the advanced feeder stand Note 2 is displayed at the same time. This guidance enables even inexperienced operators to perform work correctly in a short time without any confusion.

Note 2: This is a feeder stand which can manage the feeder location by linking with the management system.

The feeder status (such as availability and whether maintenance is required) is notified to operators through the use of LEDs.

Reusable feeders and prepared feeders can also be identified.

An AMR (autonomous mobile robot) can be used for transporting and collecting feeder magazines.

Further efficiency can be achieved because there is no need for operators to transport feeder magazines and work can be continued even during automatic transport.

Feeder packetized offline changeover can be seen at Fuji headquarters and in local showrooms around the world.

Please contact us if you have any further questions about these or any other solutions.