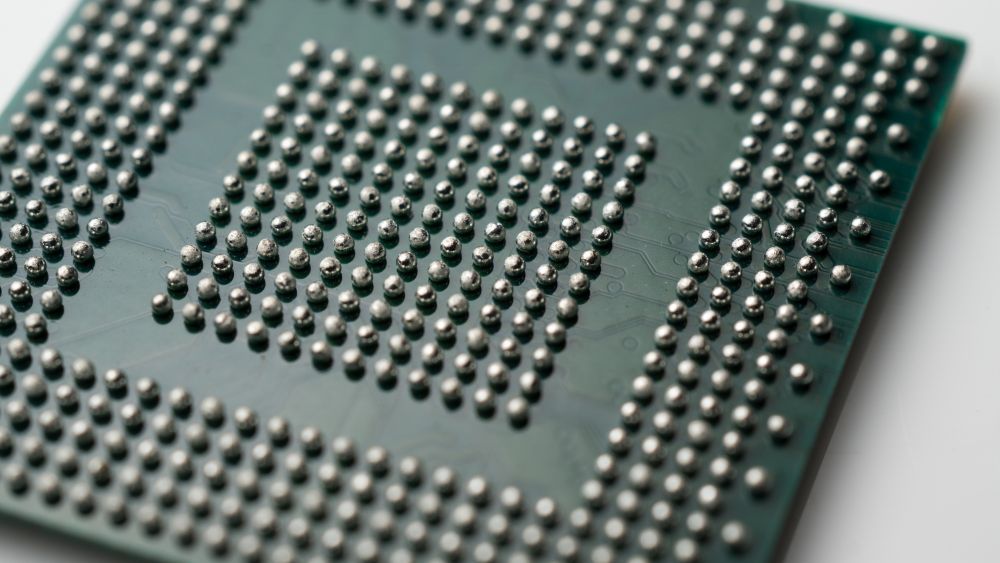

Solder ball placement solutions | Enables solder ball placement with SMT equipment

In recent years, the electronics manufacturing industry (EMS and electronics manufacturers) has begun to produce Ball Grid Arrays (BGAs) in-house, rather than relying on procurement from external manufacturers.

However, dedicated solder ball placement machines are expensive and the high cost of introducing equipment, such as the need for SPI machines (solder ball inspection machine) to check for missing placements remains a major issue.

Fuji offers solder ball placement solutions that do not require dedicated machines to resolve these issues.

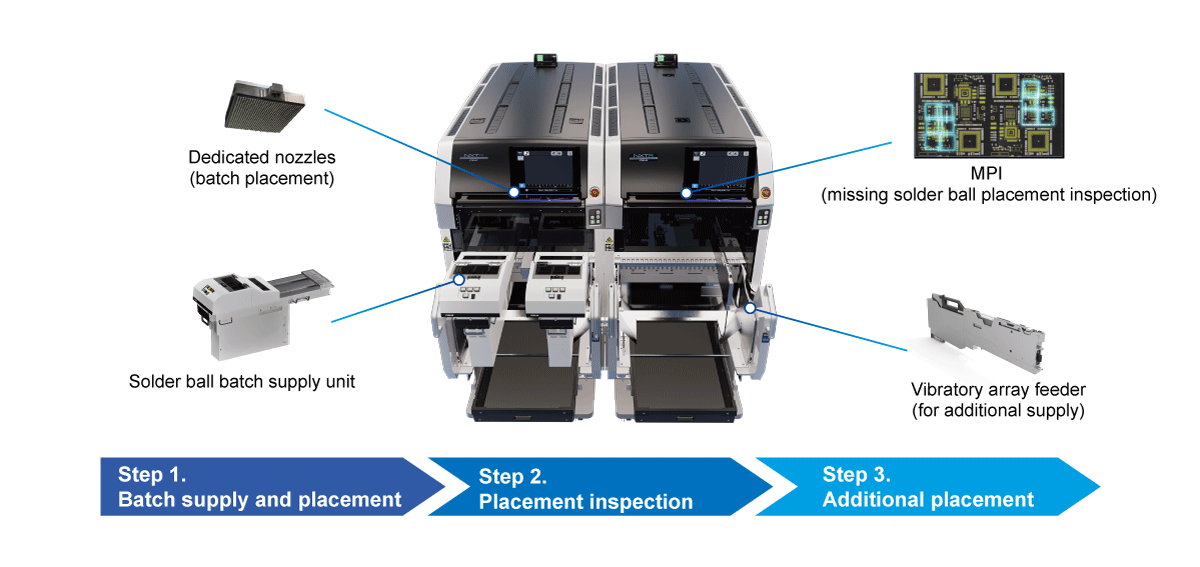

Without introducing dedicated machines, simply loading dedicated units on NXTR S model placement machines enables one-stop processing from batch solder ball placement to inspection and replenishment.

Solder ball placement can be performed by loading dedicated units on the NXTR S model.

Solder balls are picked and placed in batches using solder ball supply units and dedicated nozzles.

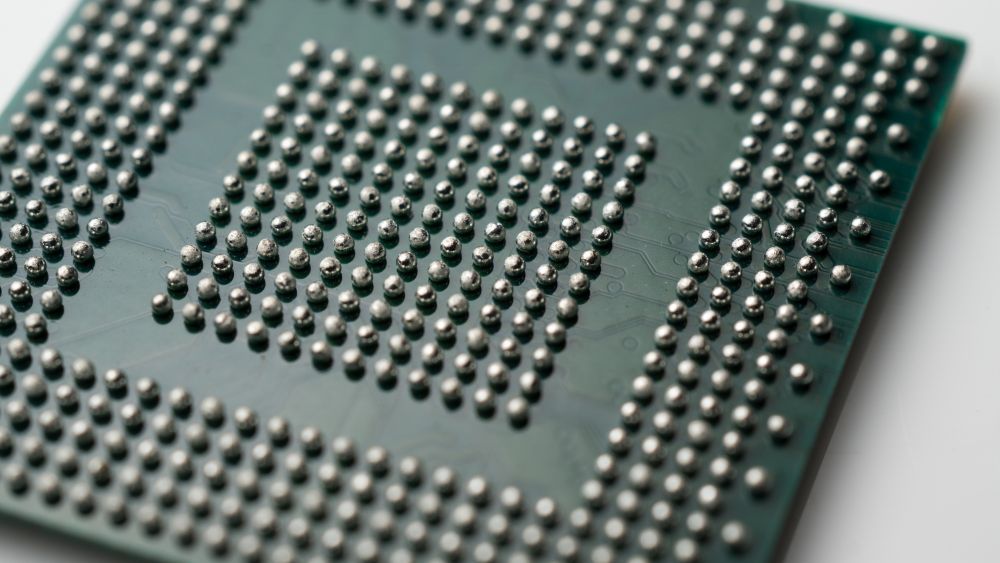

Missing solder ball placements are automatically detected after placement by the MPI function on the NXTR.

For detected missing locations, additional placement is performed individually using a vibratory array feeder.

NXTR inspection function automatically detects missing solder ball placements.

By performing additional placement at the detected locations, high quality production with minimal waste can be achieved.

Solder ball placement can be introduced with minimal investment because dedicated machines and inspection machines are not required.

Solder ball placement can be performed just by loading dedicated units on the NXTR S model.

When solder ball placement is not being performed, that NXTR machine can be used as a standard placement machine.

By supporting a wide range from BGA production to panel placement, the operating rates of production equipment can be maximized.