Halving the time to start production: Moving toward a printing process that achieves stable quality for everyone – Introducing a new support tool that brings out the power of the production floor. –

When ramping up mass production, operators often need to repeatedly run test printing to determine the best printing parameters. This work is highly dependent on the experience and intuition of the person in charge, and differences in skill can cause variations in start-up time and quality. Determining the optimal conditions for each product is not easy, even for experienced workers. As a result, the printing process has had long-standing issues, such as lengthy setup times and difficulty for new operators in achieving consistent quality.

Manpower shortage and the difficulty of passing down expertise

- The need for immediate workforce development

In recent years, labor shortages have become even more severe throughout the manufacturing industry. The SMT field is no exception. In addition to the retirement and transfer of skilled workers, it is becoming increasingly difficult to secure new personnel every year. Therefore, a major challenge for production sites is not only to maintain production with a limited number of personnel, but also to continue stable output without compromising quality.

It is necessary to quickly bring new employees into the workforce and establish a stable production system in a short period of time.

That is the most important theme for the SMT field in the future.

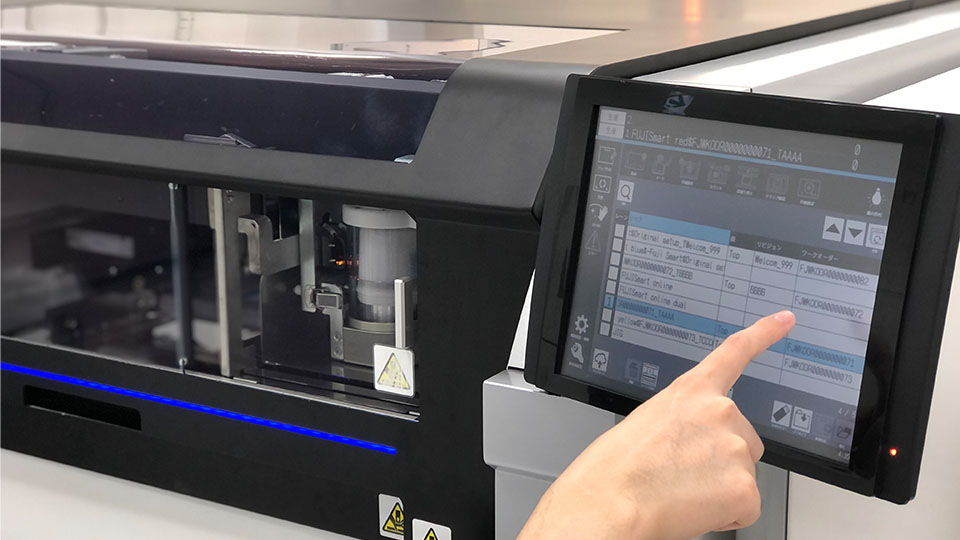

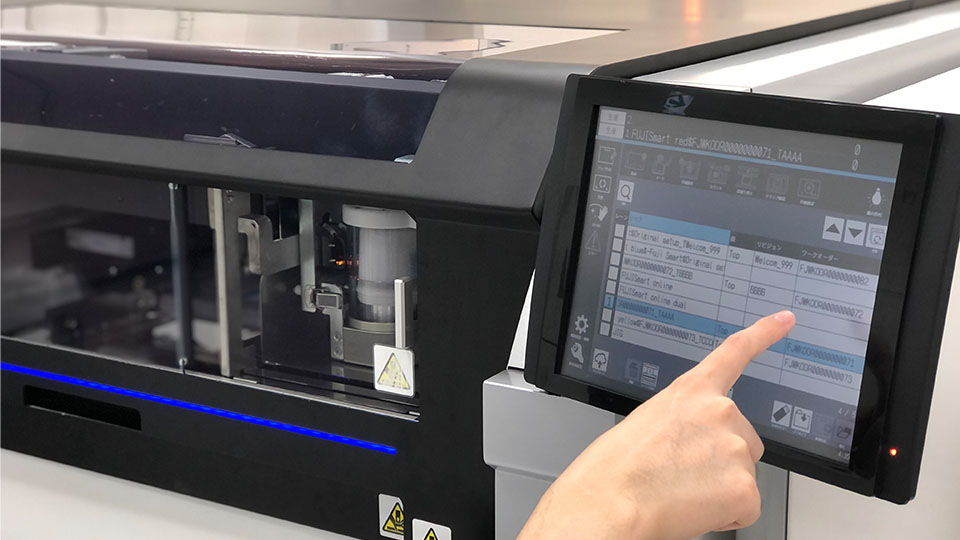

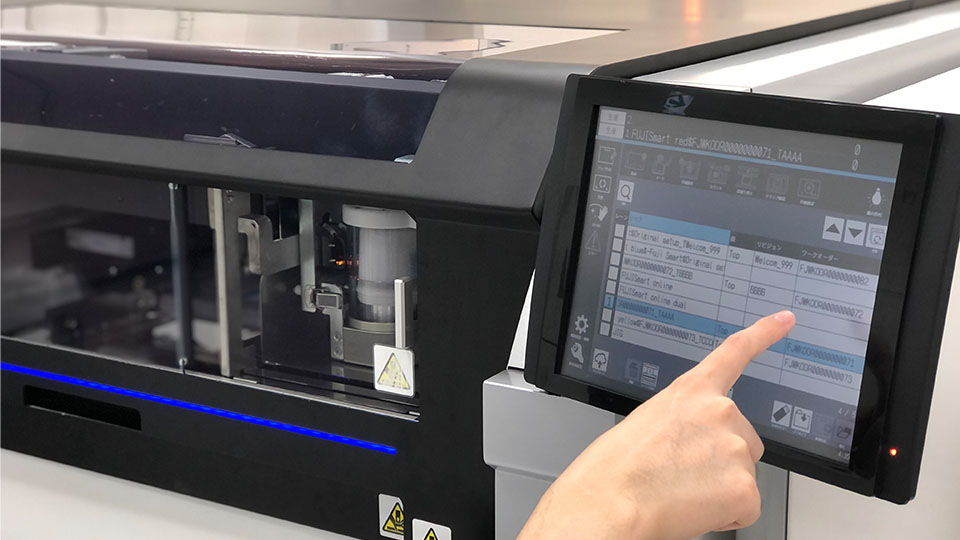

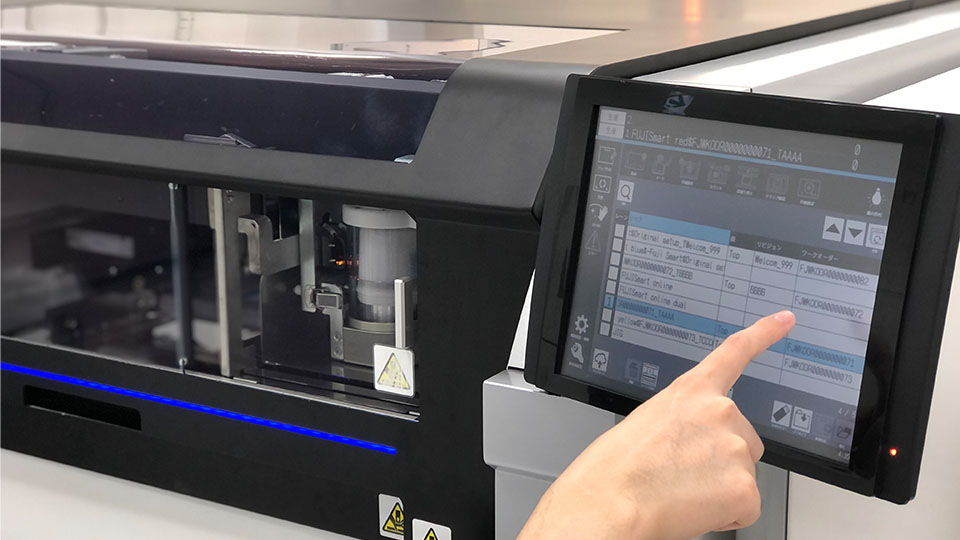

The solution to this problem is the Printing Navigator, a function that automatically presents printing parameters.

The tact time (cycle time) of the production line must match that of the placement machine and reflow oven. The Printing Navigator automatically presents the optimal printing conditions (such as squeegee speed, pressure, and snap-off speed) that meet these conditions when the target cycle time is entered and the button to automatically create parameters is pressed.

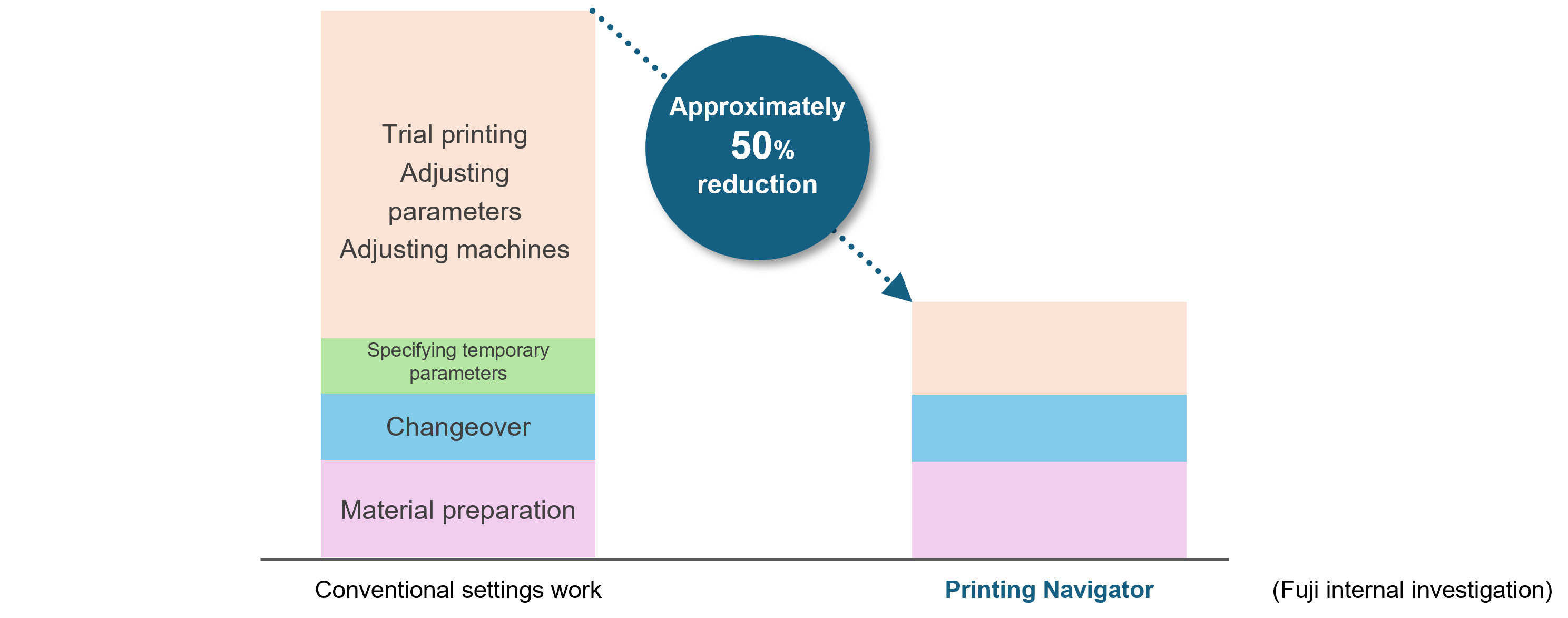

In addition, if an unstable element or defect occurs during test printing, users can simply select the problem, and the system will automatically adjust to the optimum conditions. This significantly reduces start-up time taking about half the time of conventional methods.

Note: Applicable machine: NXTR PM

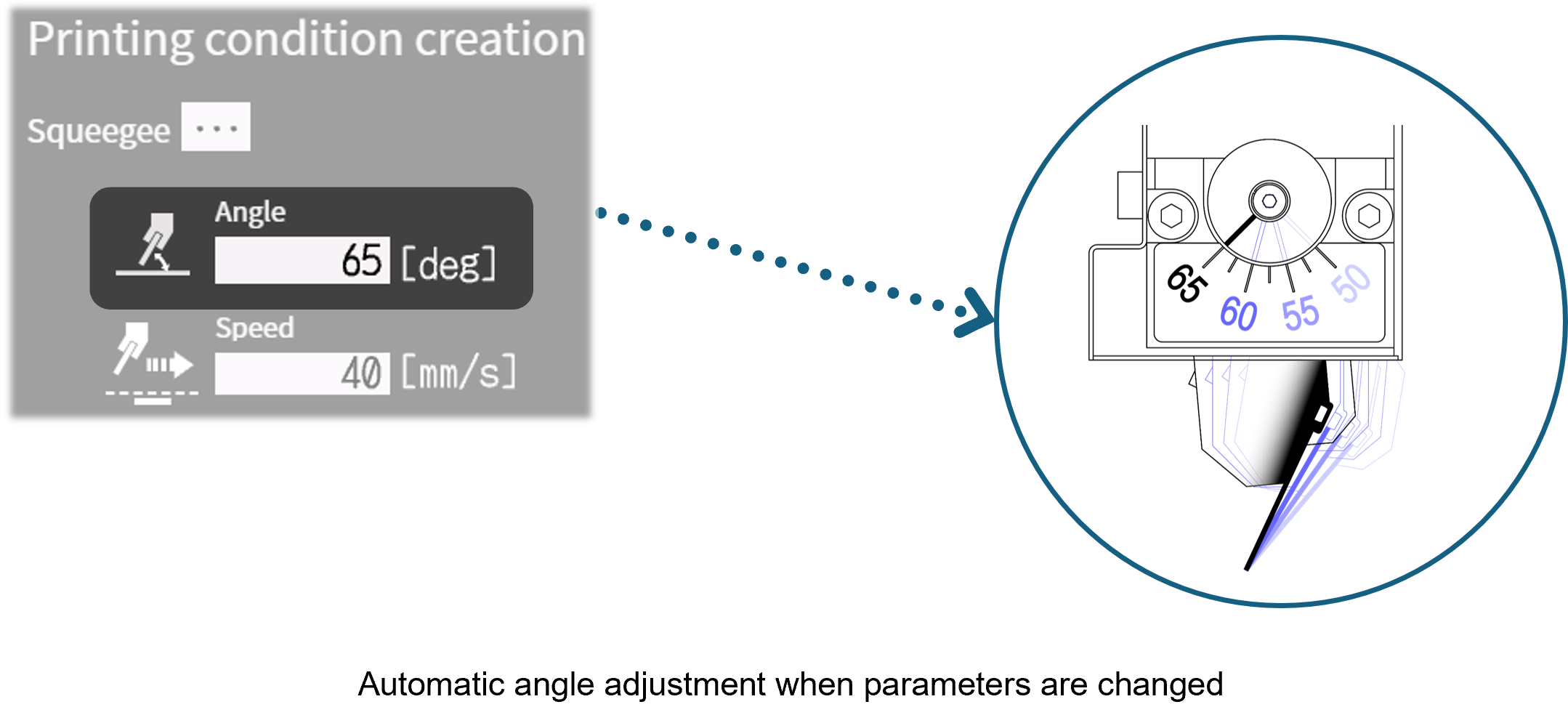

A further improvement is the new automatic angle adjustable squeegee function.

Once the optimum angle presented by the Printing Navigator is reflected, the squeegee automatically changes to the specified angle. Therefore, it is no longer necessary to open the cover and manually adjust the angle unlike in the past.

In addition, by using automatic angle adjustable squeegees, the history of squeegee angle changes can be automatically recorded. Other printing parameters aside from the squeegee angle can also be kept in the change history, which is useful for improving work traceability and optimizing conditions.

Notes: Option (can be retrofitted to already shipped machines)Supported machine: NXTR PM

Printing quality is maintained by daily condition checks

Before adjusting parameters, first check the condition of the machine and materials. The condition of the machine and materials is the most fundamental and important factor in achieving high-quality solder printing. Even the slightest error, such as stencil dents, squeegee chipping or deformation, or foreign matter adhering to the backup pins, can significantly affect print quality. Adjusting parameters while overlooking these physical factors makes optimization difficult and wastes time.

Keeping machines and materials in good condition is the first step toward high-quality printing.

We recommend making a habit of checking the machines before and after use on a daily basis and promote the creation of workplaces that support stable quality.

The Printing Navigator continues to evolve. As labor shortages become more serious and the globalization of production bases continues, we are developing a system that supports human skills, which are considered difficult to pass on, and provides an environment in which anyone can achieve the same quality.

Quality stays the same, even as operators change – that’s the next-generation printing floor Printing Navigator strives for.