Many of our customers are already using 3D coplanarity checks to check for parts with bent leads before they can result in placement defects. However, while the 3D coplanarity check unit is an accurate and versatile tool for detecting potential defects, there are also many who could benefit from the function to check for bent leads but have passed on it when weighing up the merits vs the initial costs of a unit that has a full-range capacity to check for missing or misshapen bumps, as well as missing and warped leads.

Because of this, we have developed an all-new lead checking unit.

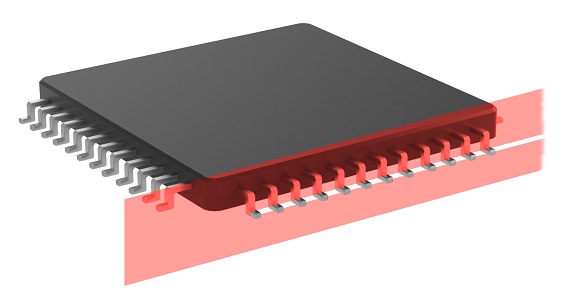

New! Laser-type lead check unit

The laser-type lead check unit has high cost performance and focuses on checking leaded parts that are easily warped by external influences such as SOPs, QFPs, and connectors. Because this check unit is loaded to unoccupied space within the machine, it can easily be attached to machines already being used in production.

Basic specifications

| Applicable machines: | AIMEX IIS, AIMEX III, AIMEX IIIc |

|---|---|

| Applicable parts: | Leaded parts such as SOPs, QFPs, and connectors |

| Applicable part size: | Up to 45 x 45 mm or 32 x 100 mm (including leads) |

| Lead thickness: | 0.1 to 1.0 mm |

| Detected lead deviation: | 0.1 mm or more (height) |