Production Quality Changed by Low Impact Placement

- Is the placement quality for very small parts stable?

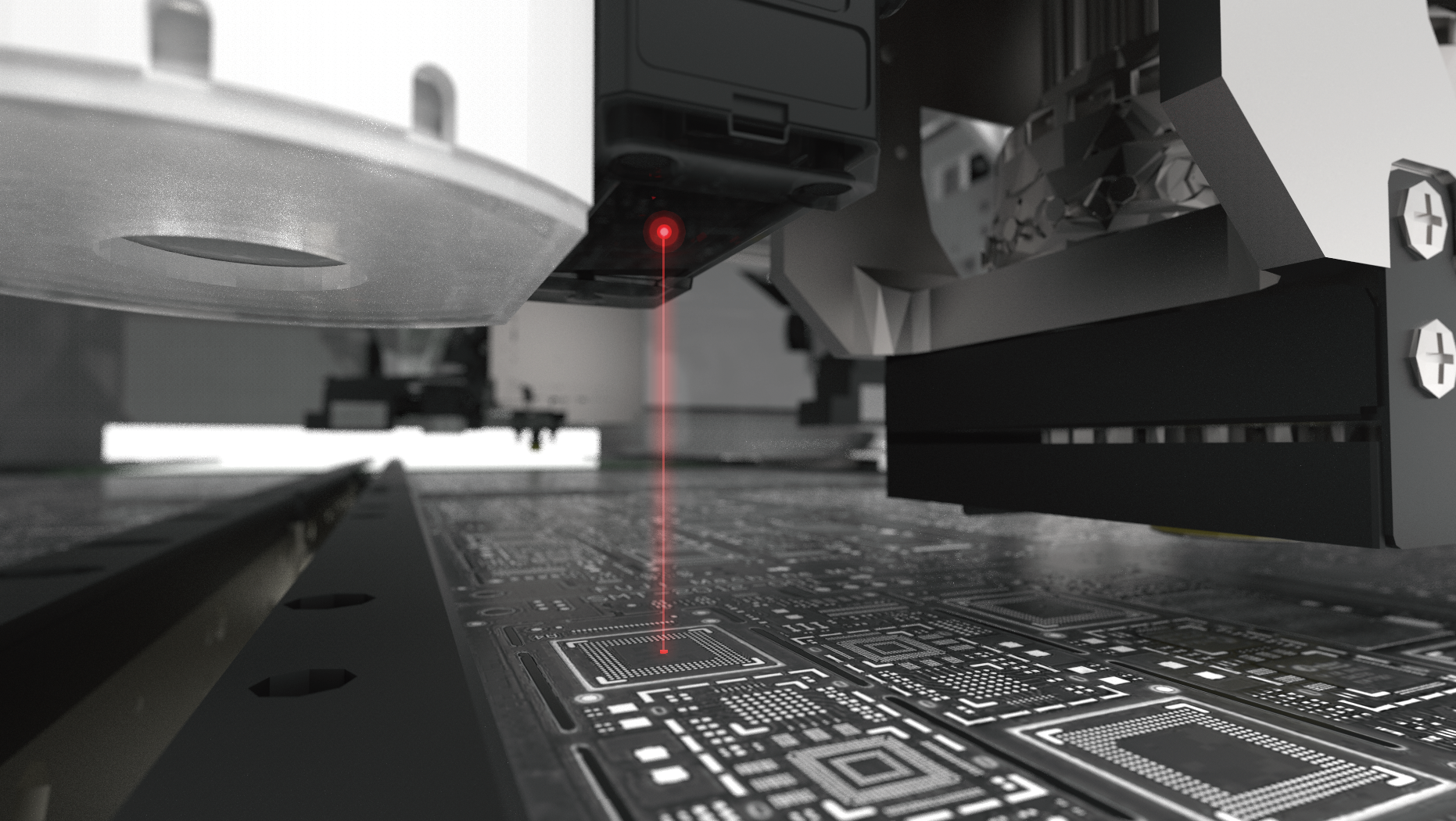

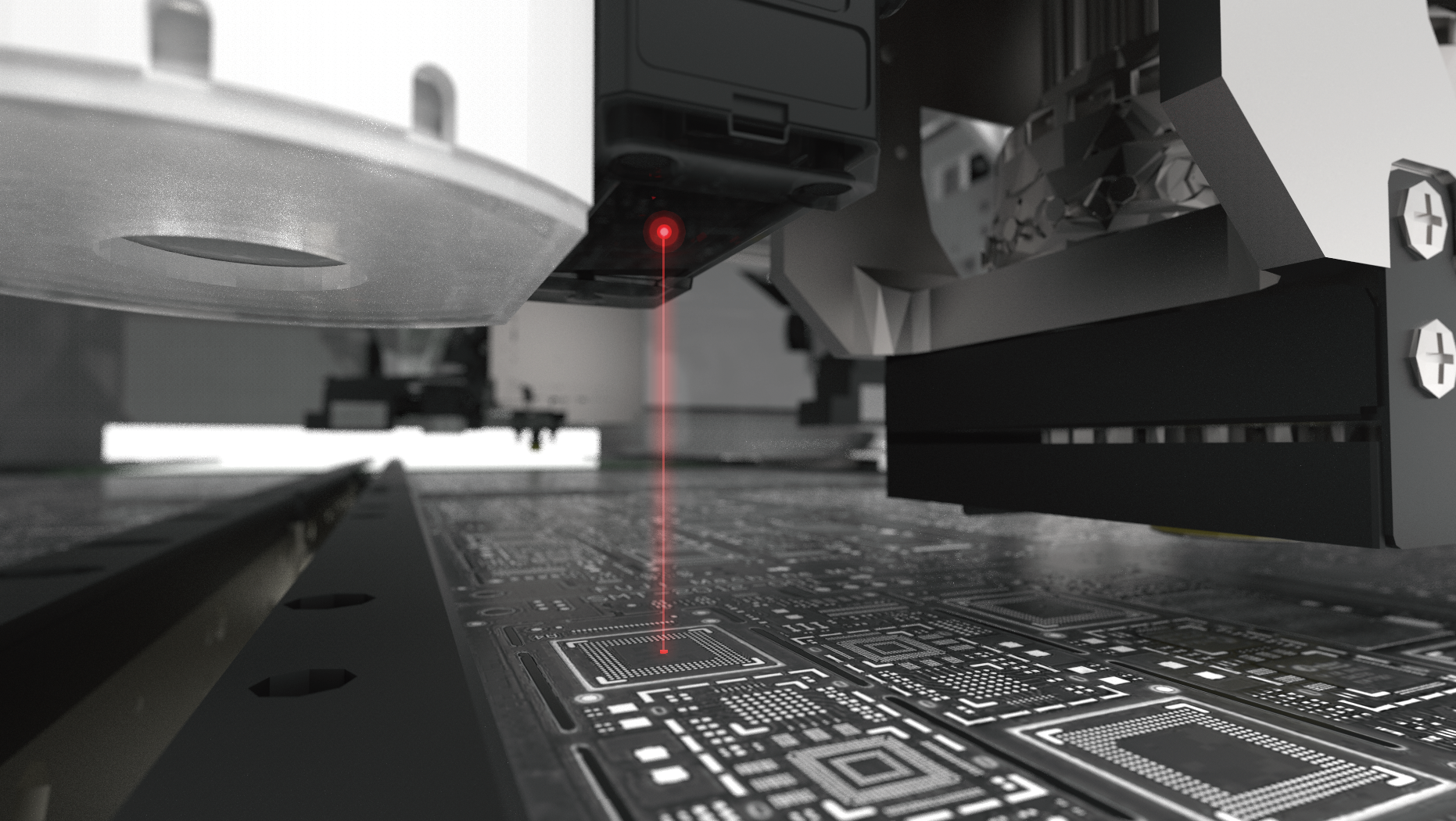

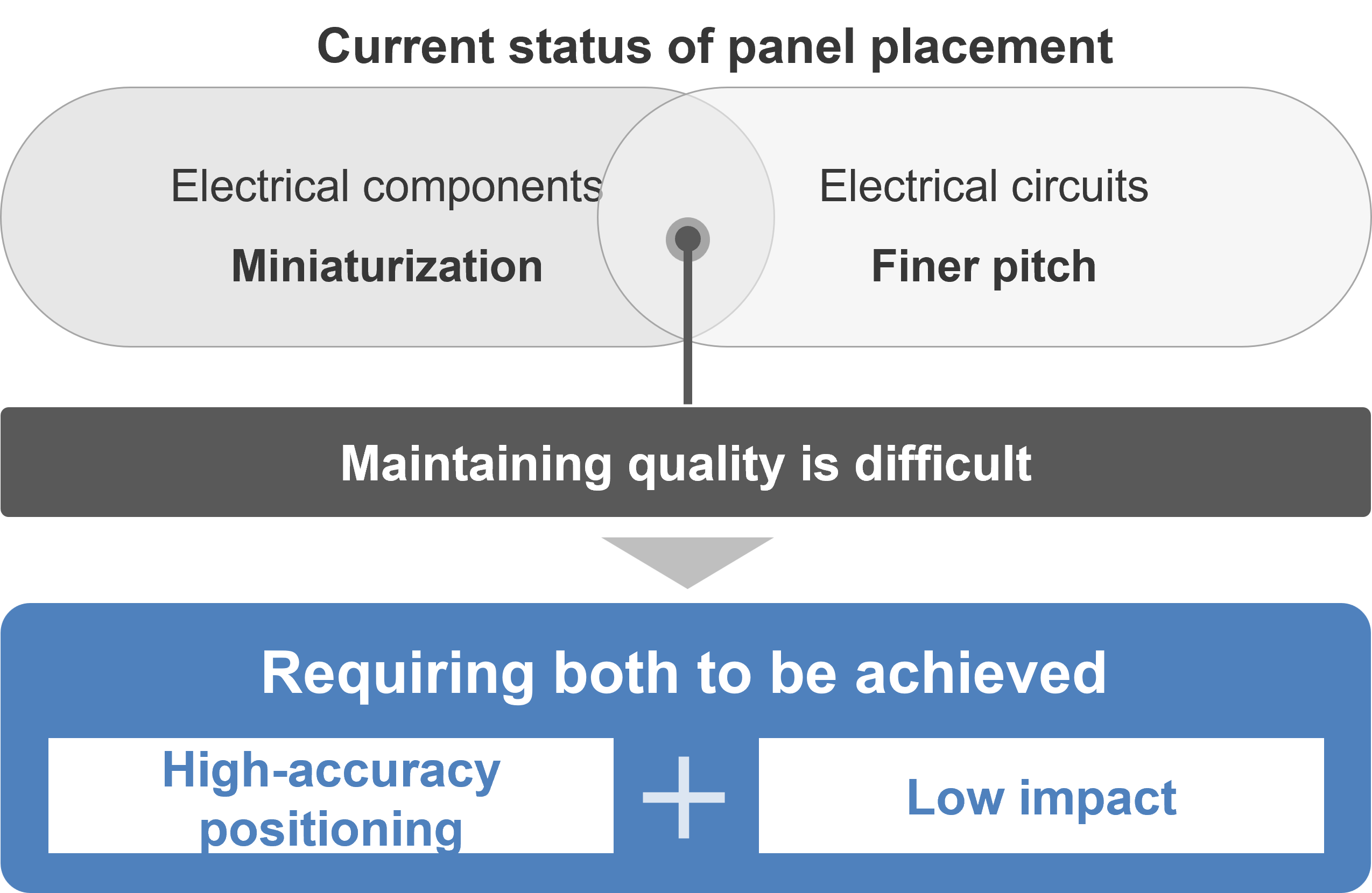

With the proliferation of very small parts and thin panels, the placement process has become ever more delicate. As components become lighter, thinner, and smaller, and panels are more easily deformed than ever before, the slightest change in conditions can affect placement quality.

As a result, the following problems commonly occur at each site. - Handling of parts has become more critical, leading to increased variation in placement results.

- The condition of the panel is inconsistent, affecting placement quality.

- Defective measures worsen production tact.

- Differences in operator judgment and skill lead to quality differences.

The limitations of relying solely on on-site efforts are becoming apparent.

Limitations of conventional approaches

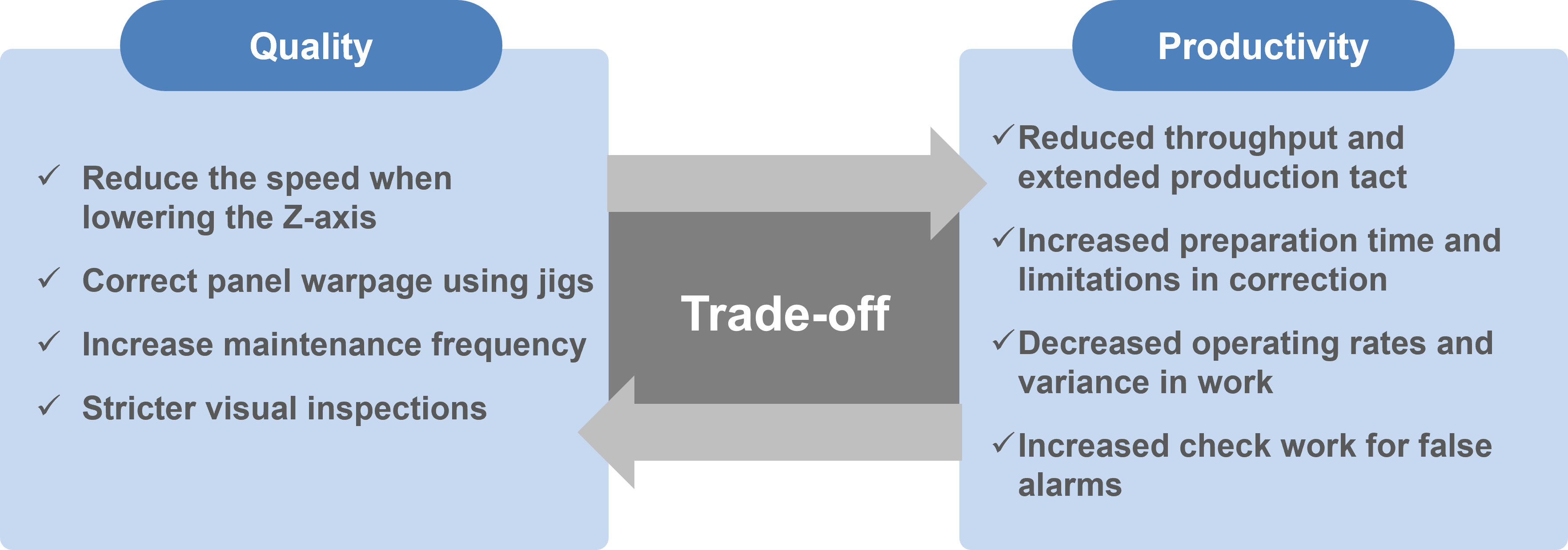

■ Why do common countermeasures reach their limits?

In production sites, the following actions are common to protect quality. - Lowering the placement speed

- Correcting the panel condition using jigs

- Increasing inspection frequency

However, these are not fundamental solutions and produce the side effect of reduced productivity.

Therefore, relying solely on measures that extend conventional approaches is no longer sufficient to keep up with the placement issues of the miniaturization era.

Introduction of the latest approaches (overview)

■ What is the new approach that achieves both quality and productivity?

In order to stabilize the placement quality, it is necessary to comprehensively optimize multiple factors that affect the placement process.

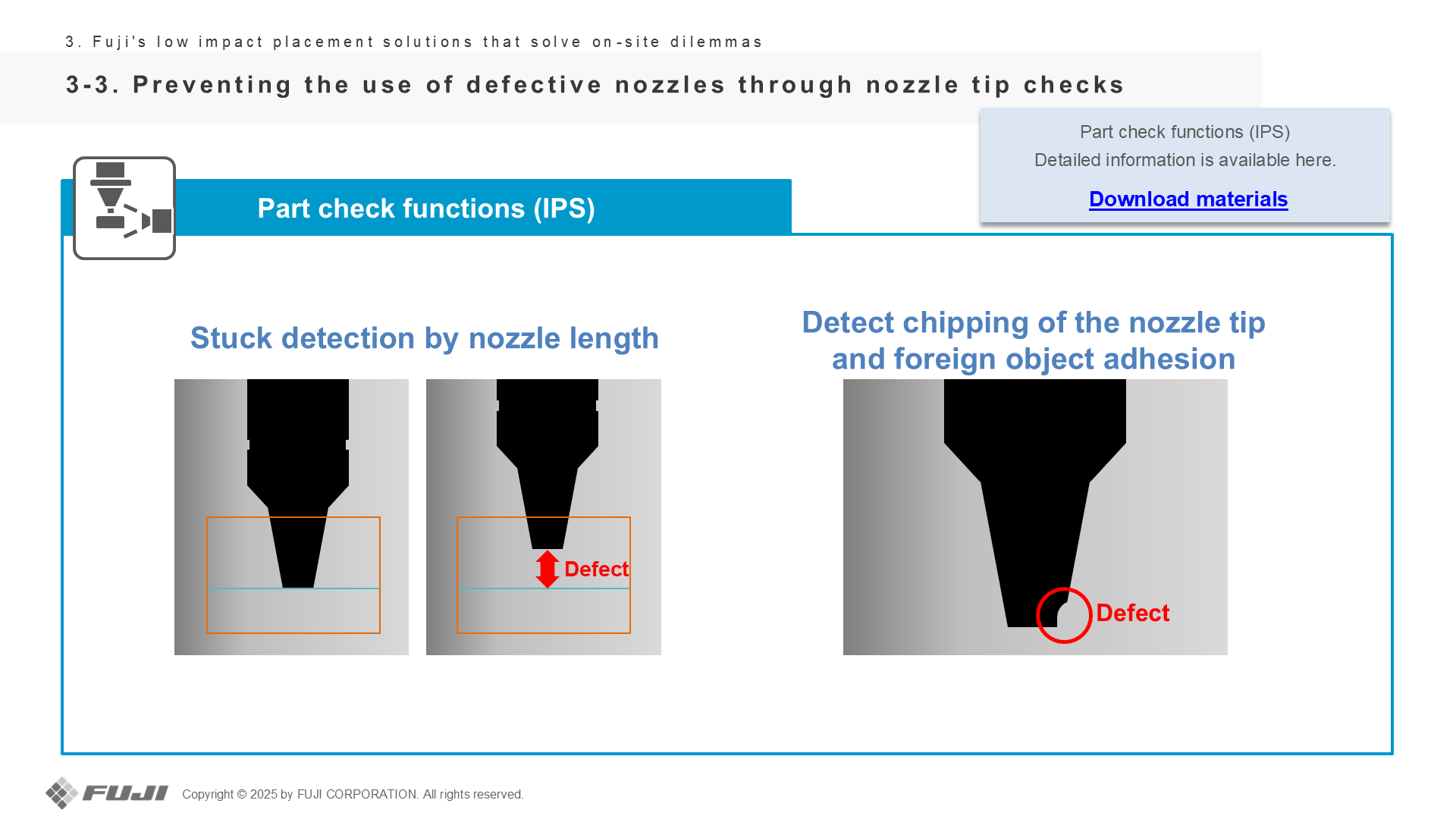

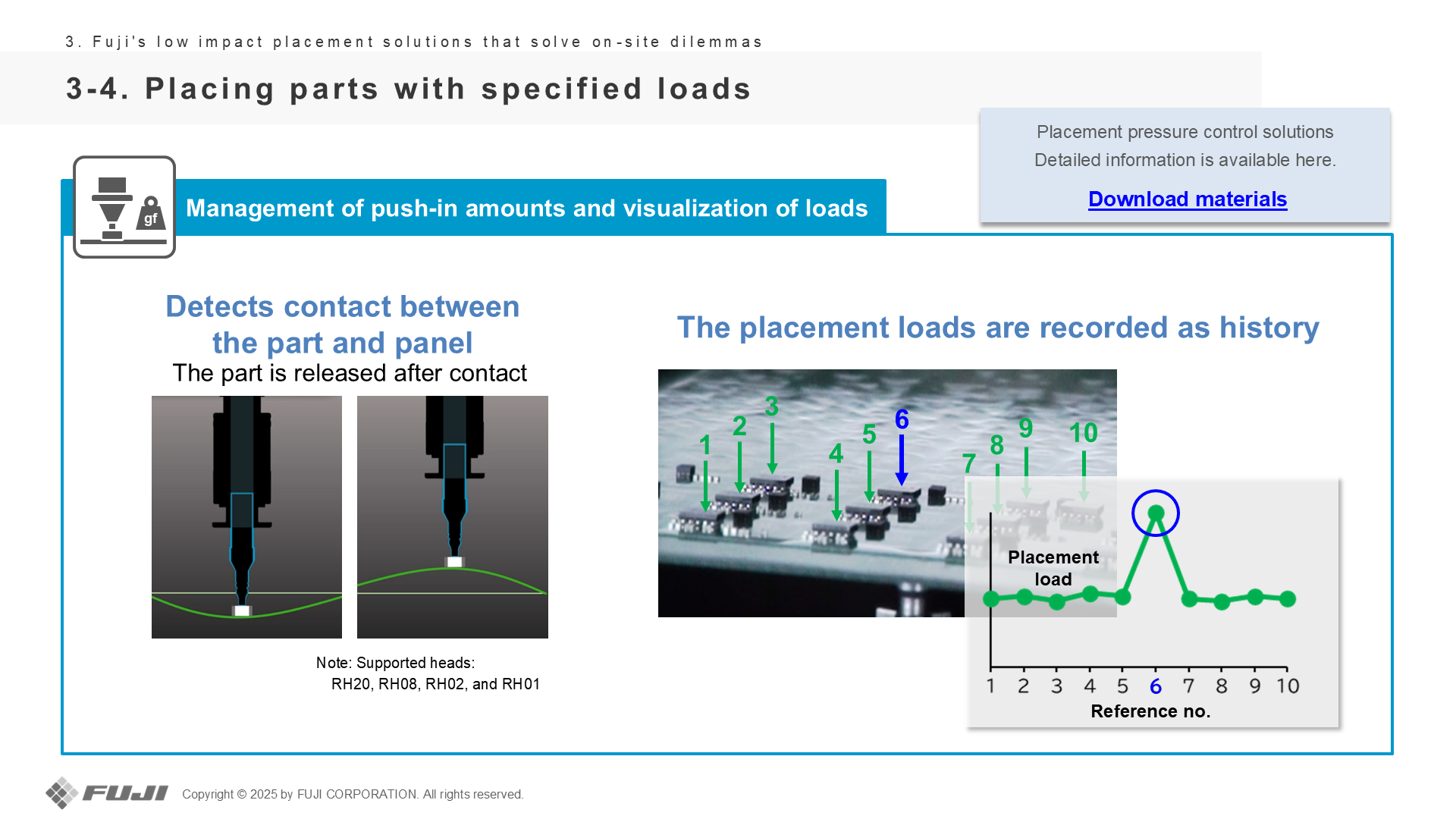

The key points are support for changes in the condition of materials, placement load management, and reducing impact during placement.

Details are explained in the downloadable documents.

This document outlines the essential principles required to achieve both quality and productivity in the evolving SMT sites.

If you have placement quality issues, please take a look at this document.