Takaya Corporation (Est. 1894, Okayama Prefecture) is a company with a long history in various electronics industries both in Japan and overseas.

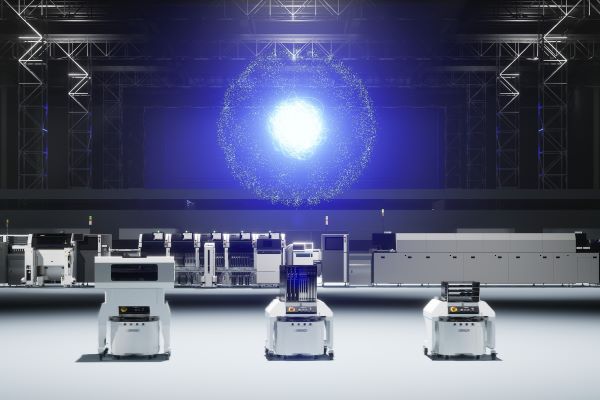

In recent years, Takaya has been focusing on reducing the time required for product changeover and searching for production materials, especially in the context of high-mix, low-volume production. In 2021, Takaya introduced FUJI Smart Factory (FSF) with its combination of system and automation technologies.

As a result, product changeover and parts supply within the SMT line were automated, and significant labor saving was achieved.

FSF also allows factories to entrust even new workers with managing production lines, with less time required for passing on know-how to new workers.

This content is for members only.

This content is for members only.