Controlling placement load

To be able to maintain quality when placing electronic parts that are increasingly smaller, thinner, and lighter, it is necessary to have a high level of stopping accuracy as well as low load on the parts when placing them.

Low impact placement is a prerequisite for controlling the load on parts and solder.

The following introduces mechanical features of our products to deliver low impact placement and also sensing technologies for placing parts at an appropriate height while securing stable tackiness with the panel in mind.

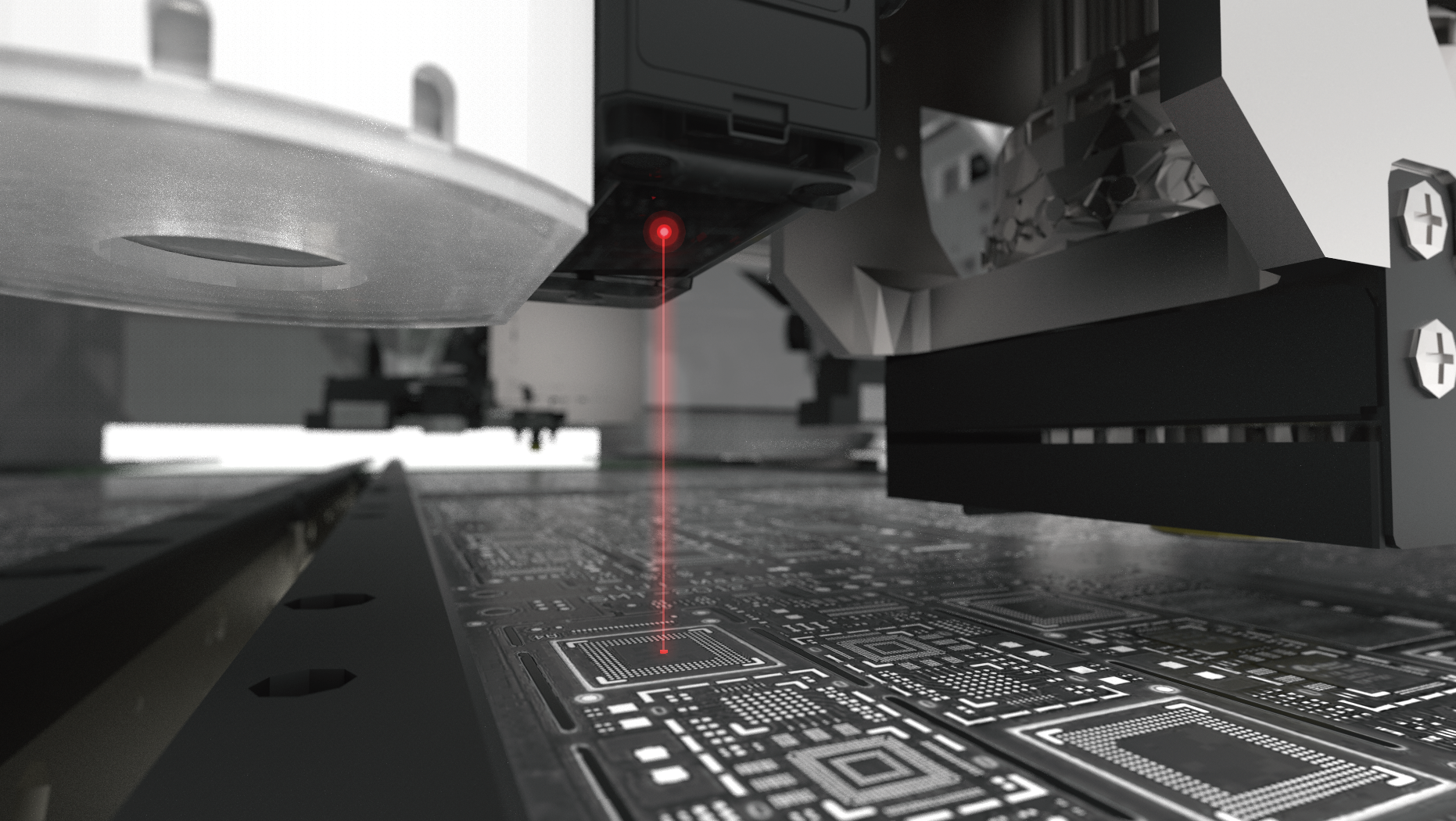

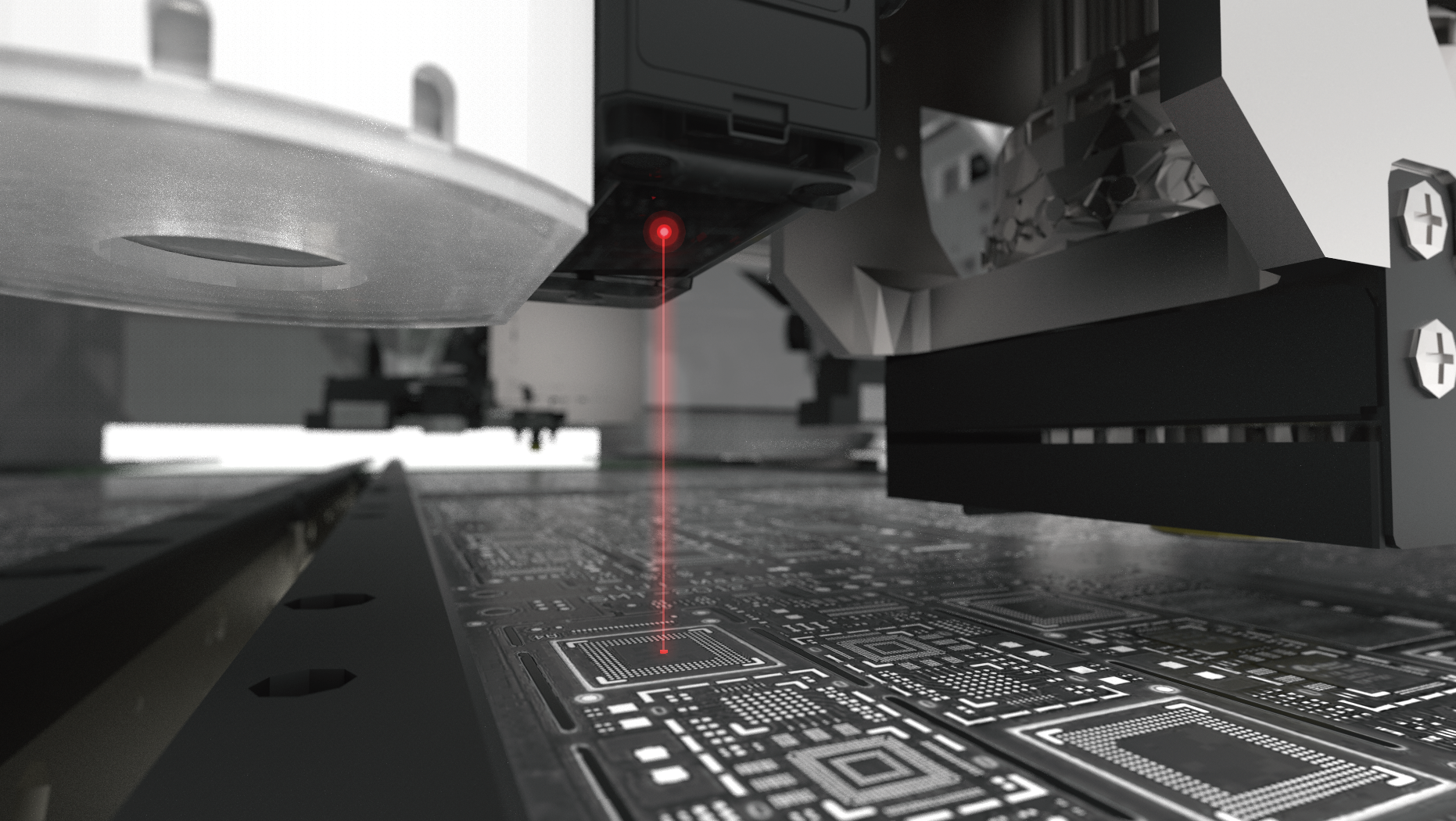

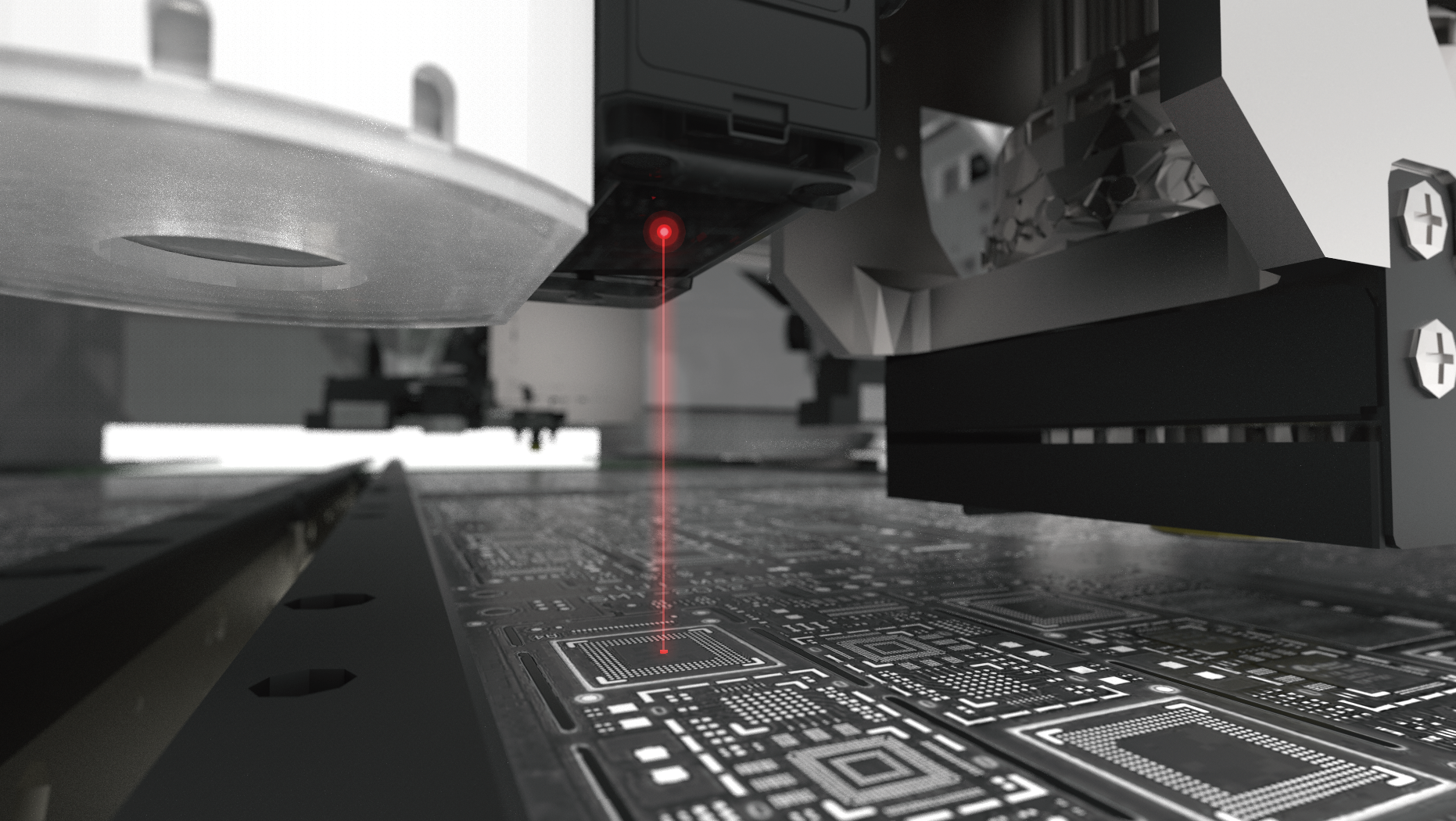

Measuring the panel warpage by a laser sensor allows offsetting the placement height, which assists in preventing damage to parts, short circuits by solder bridging, and placing parts before contacting the panel.

Using this function together with part height checks by IPS achieves greater accuracy in placement height control.

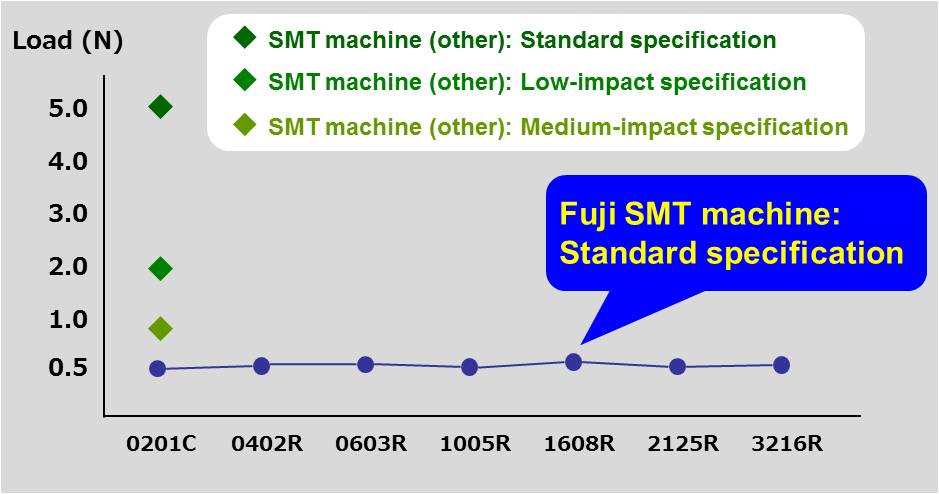

Fuji nozzles are crafted from two pieces. This mechanism absorbs impact from placement of parts to prevent damage to parts and solder bridging.

Placement does not require reduction of the nozzle lowering speed, so part placement with such low impact of 50 gf can be achieved without a drop in the tact time.

*H24S and H24A heads

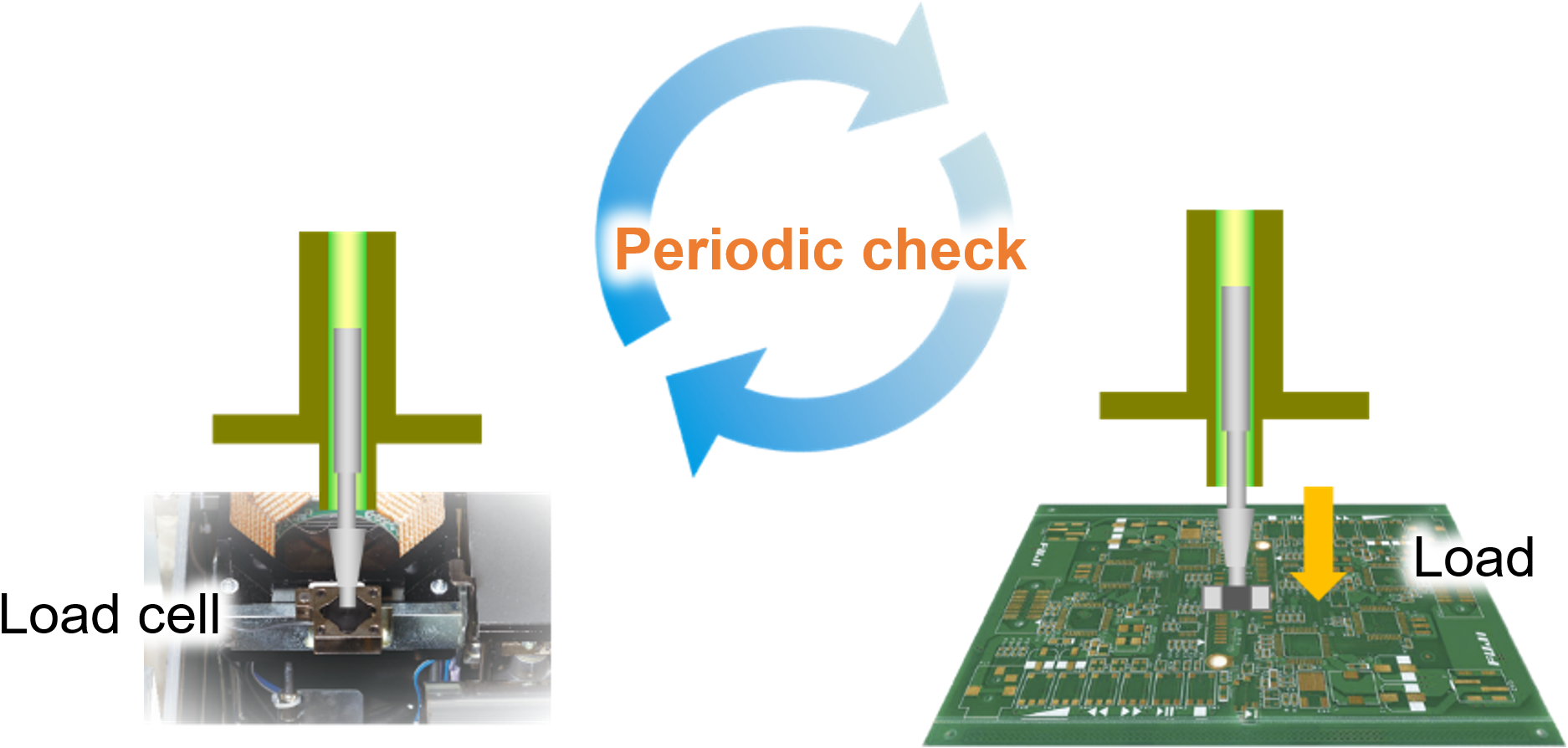

The actual push-in amount until it reaches the specified load is measured, and then while applying accurate load based on that measured value, parts are placed.

This is effective for parts for which a placement load needs to be kept low and parts that are to be placed using a significant amount of load.

Using together with the panel height detection delivers placement with more stable loads.